Efficient heat preservation dead head production device

A technology for production equipment and thermal insulation risers, which is applied to casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of easy deformation of risers, low production efficiency, and inability to achieve continuity, etc. Simple, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

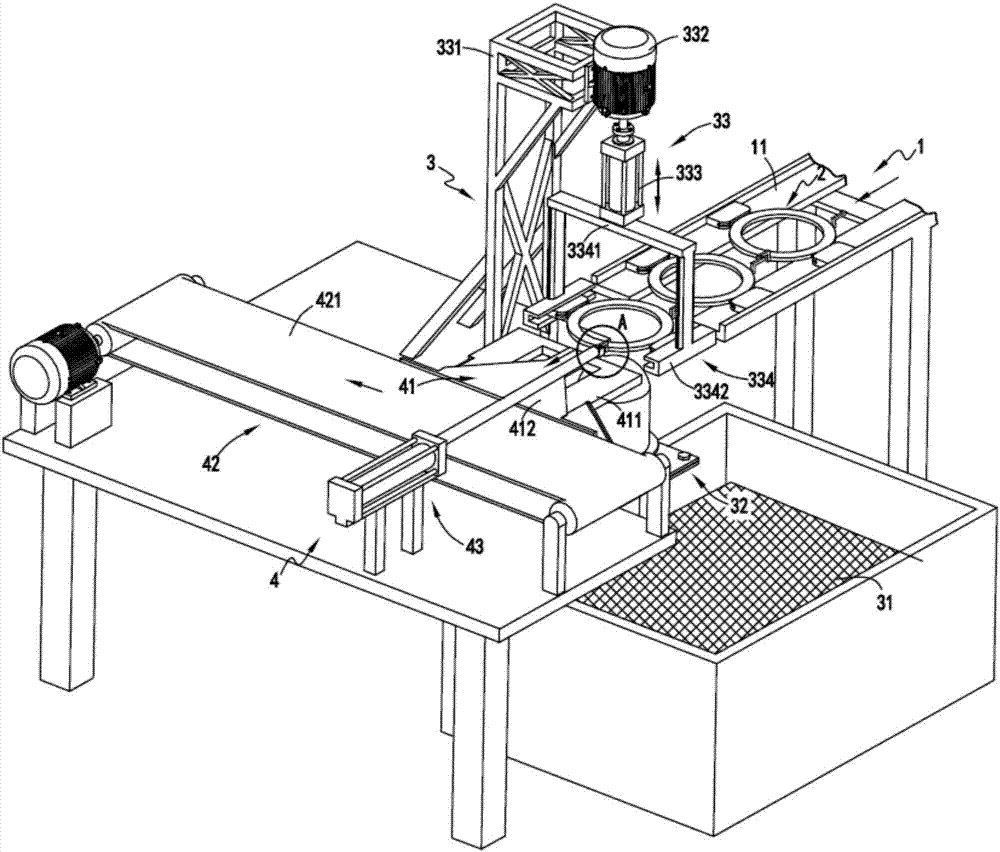

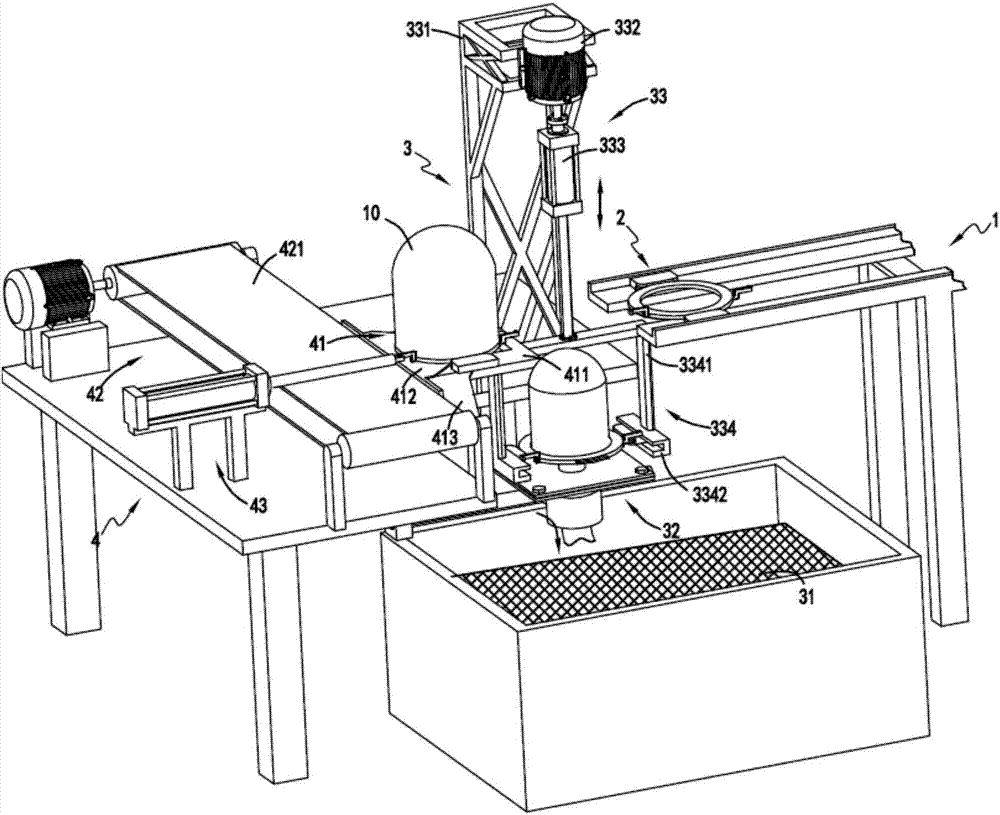

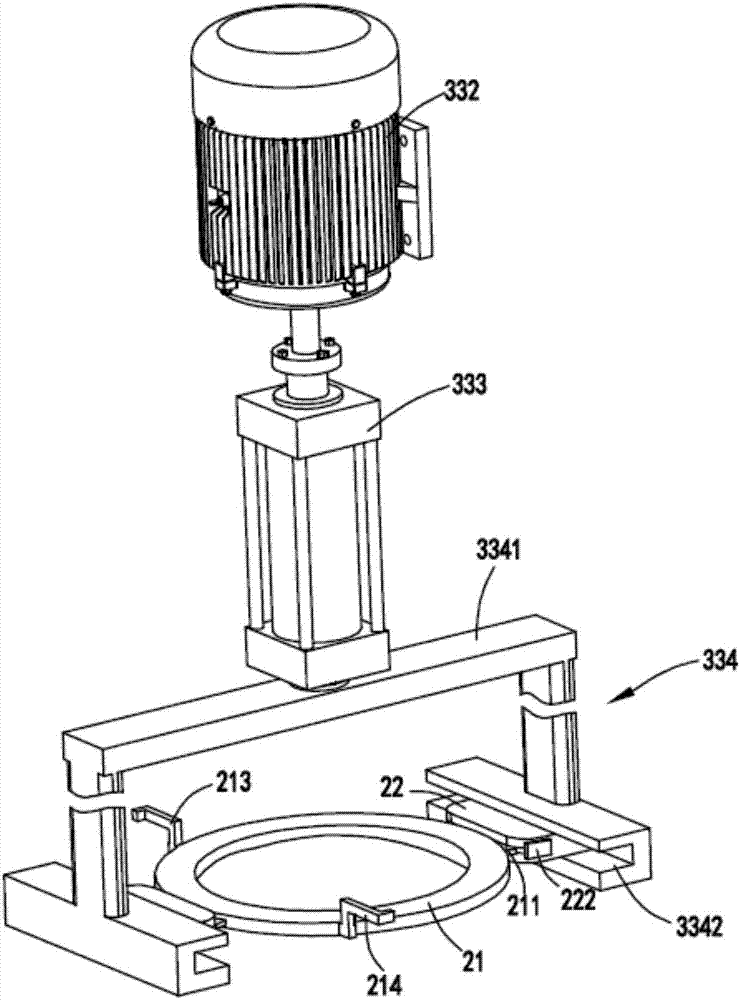

[0040] figure 1 Schematic diagram of the structure when the pallet assembly of the insulation riser is efficiently produced on the support device, figure 2 Schematic diagram of the structure when the forming device for the high-efficiency production equipment of the thermal insulation riser connects the supporting parts and starts to transfer into the mud pool, image 3 It is a schematic diagram of the structure of the lifting and rotating mechanism, Figure 4 It is a schematic diagram of the structure when the supporting device drives the tray assembly to the forming device, Figure 5 It is a schematic diagram of the structure when the supporting part is separated from the supporting part and the forming device drives the supporting part to turn over, Figure 6 is a schematic diagram of the structure of the component separation mechanism, Figure 7 is a schematic diagram of the structure of the pallet assembly, Figure 8 It is a schematic diagram of the front view when t...

Embodiment 2

[0051] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the pulling mechanism 43 includes a telescopic device 431 and a hook block 4312 fixed at the end of the telescopic rod 4311 of the telescopic device 431; The front end is provided with a hook block a213 that cooperates with the hook groove 4313 opened by the hook block 4312, and the rear end of the support member 21 is provided with a hook block that cooperates with the hook block a213 of the next support member 21. b214.

[0052] Further, the bent portion 4314 of the hooking block 4312 fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com