Cold rolling processing line stepping beam steel coil tracking method

A walking beam and processing line technology, which is applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as loss and coil tracking errors, and achieve convenient maintenance, simple programming, and efficient and stable material tracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further illustrate the technical solution of the present invention, the present invention is described in detail with reference to the accompanying drawings.

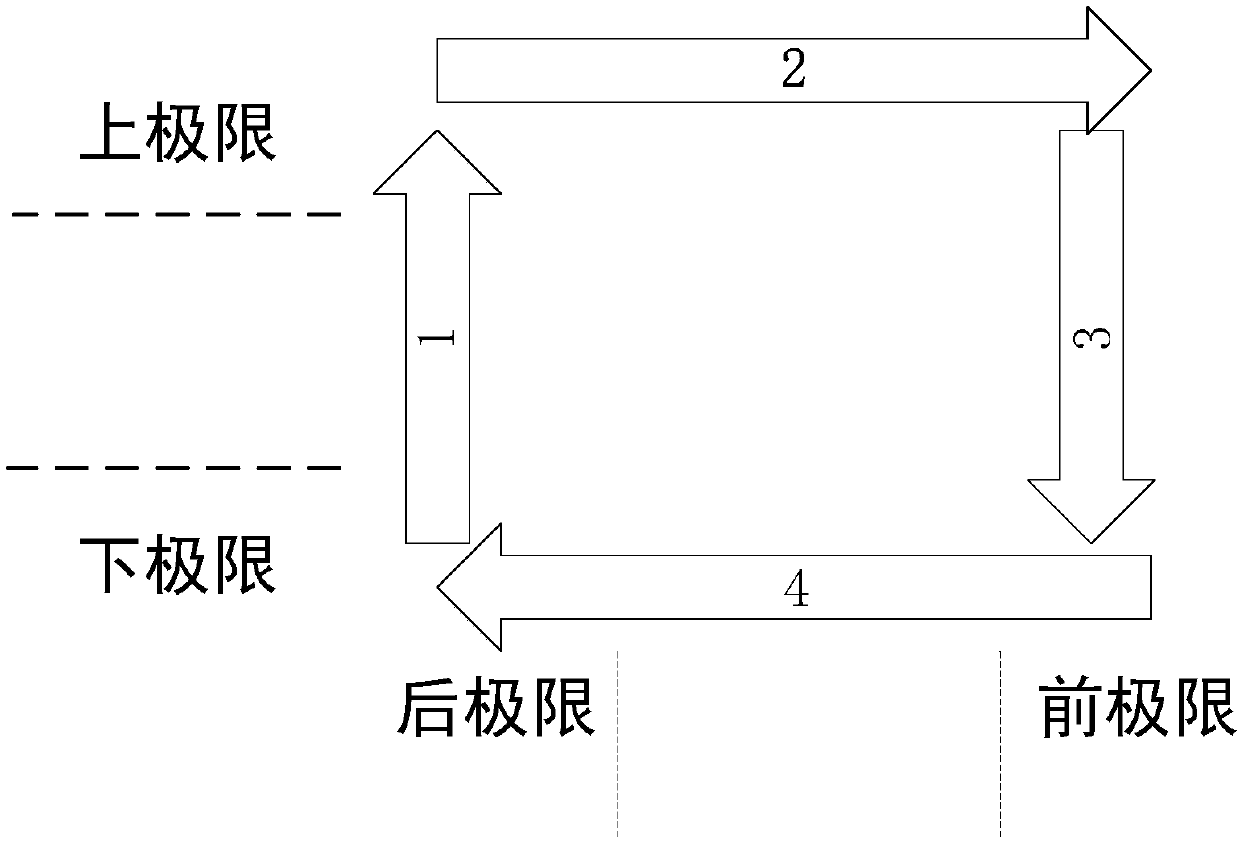

[0046] In the walking beam coil tracking method of the cold rolling treatment line implemented according to the present invention, the typical operating model of the walking beam is as follows: figure 1 Shown: wherein the walking beam movement steps are: 1. At the rear limit, rise from the lower limit to the upper limit. 2. At the upper limit, proceed from the rear limit to the front limit. 3. At the front limit, descend from the upper limit to the lower limit. 4. At the lower limit, back off from the front limit to the rear limit.

[0047] The following is combined with the specific implementation method of 3# walking beam steel coil material tracking at the exit of a continuous leveling line in a steel factory figure 1 To illustrate the present invention.

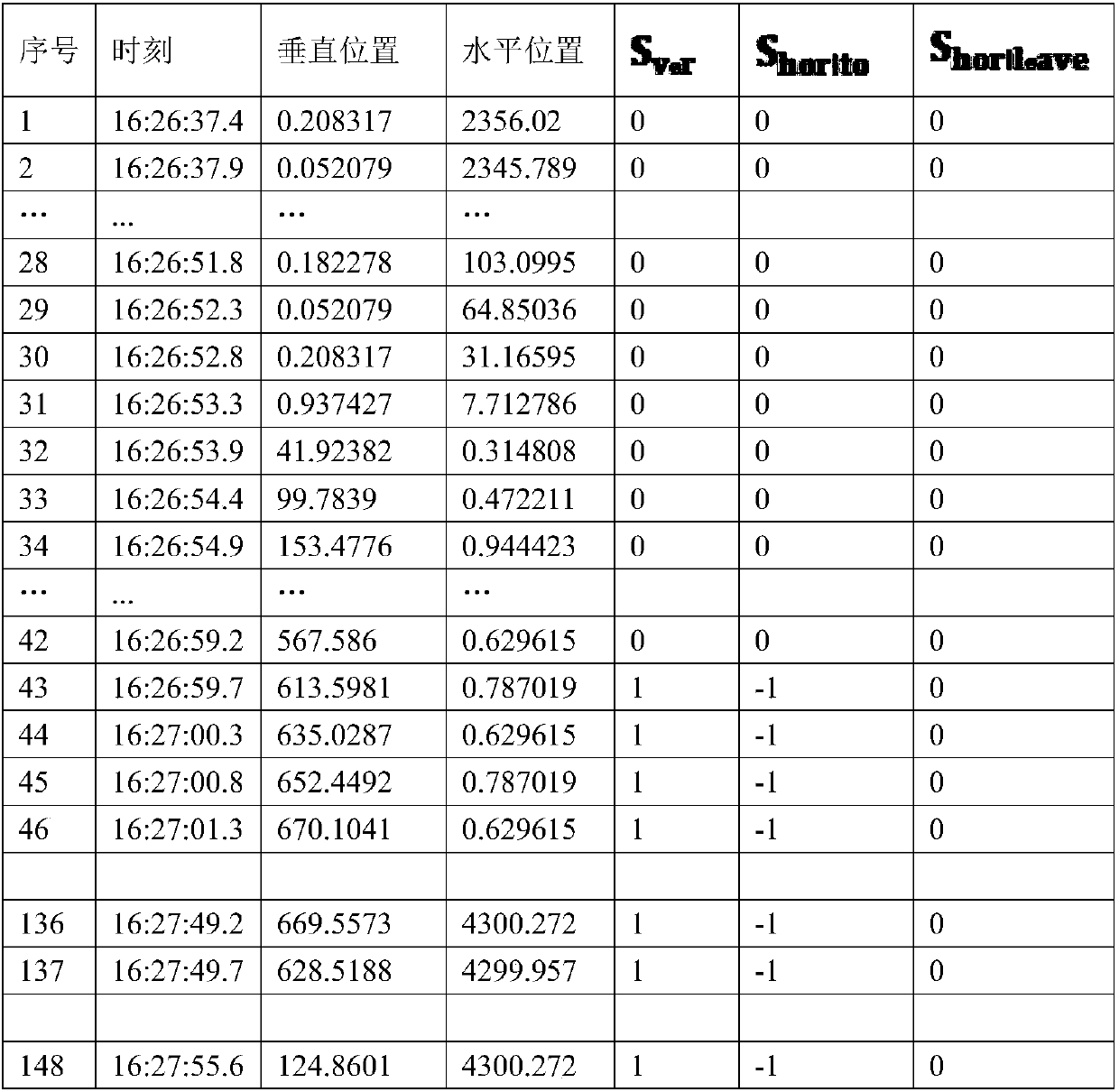

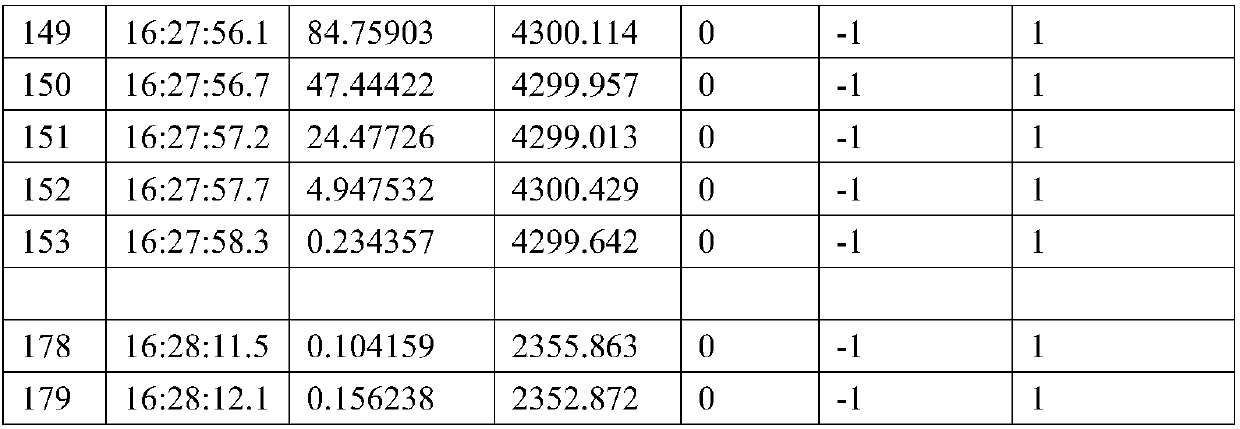

[0048] This production line adopts hie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com