Method for harmless treatment of waste incineration fly ash through hydrothermal technology

A waste incineration fly ash, harmless treatment technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of not exceeding 95%, achieve strong adsorption capacity, strong stability and The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

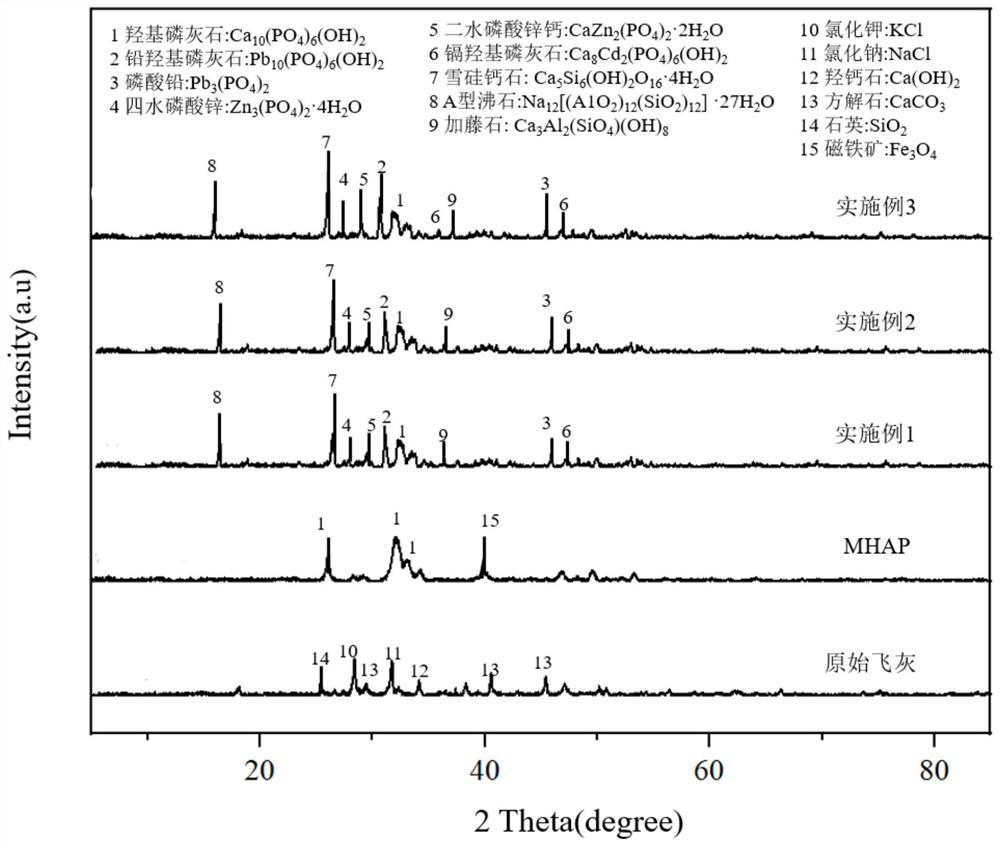

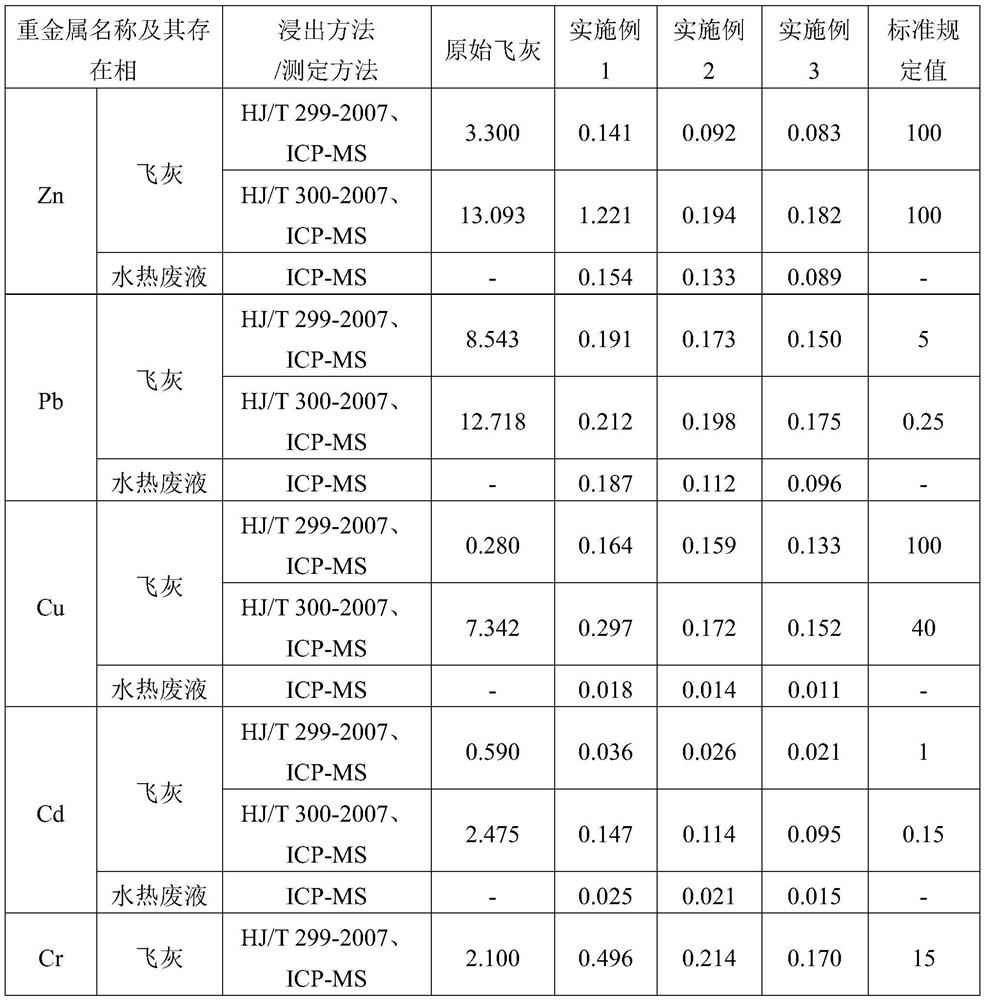

Embodiment 1

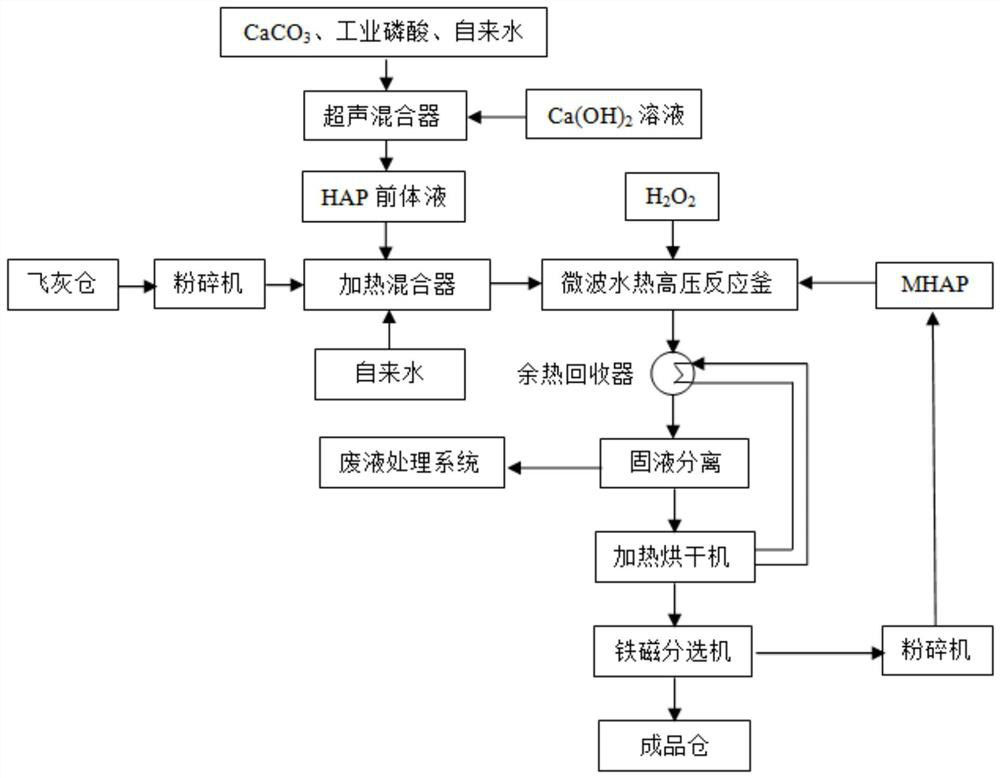

[0030] Such as figure 1 As shown, the method for hydrothermal harmless treatment of waste incineration fly ash comprises the following steps:

[0031] A. Pre-grind the collected waste incineration fly ash to make it uniform and have a particle size below 200 μm.

[0032] B. Add 10g of egg shells (calcium carbonate substance) with the inner film removed to the ultrasonic reactor, add 7mL of industrial phosphoric acid and 93mL of tap water, react ultrasonically for 30 minutes at room temperature, and let it stand until there is no more CO 2 Bubbles are generated to obtain about 100 mL of calcium phosphate salt stock solution, and then 100 mL of 0.1 mol / L calcium hydroxide is added dropwise at 10 mL / min during stirring, and NaOH is added to keep the pH at about 12 to 13, and then stirred for 1 hour to obtain 200 mL of hydroxyapatite precursor solution (HAP precursor solution).

[0033] C. Add HAP precursor liquid to the fly ash in the oscillating or stirring heater. The solid-l...

Embodiment 2

[0041] Such as figure 1 As shown, the method for hydrothermal harmless treatment of waste incineration fly ash comprises the following steps:

[0042] A. Pre-grind the collected waste incineration fly ash to make it uniform and have a particle size below 200 μm.

[0043] B. Add 10g of calcium carbonate to the ultrasonic reactor, add 7mL of industrial phosphoric acid and 93mL of tap water, react ultrasonically at room temperature for 30 minutes, and let it stand until there is no more CO 2 Bubbles are generated to obtain about 100mL of calcium phosphate salt stock solution, and then 100mL of 0.1mol / L calcium hydroxide is added dropwise at 10mL / min during stirring, and NaOH is added to keep the pH at about 12-13, and then stirred for 1 hour to obtain 200 mL of hydroxyapatite precursor solution (HAP precursor solution).

[0044] C. Add HAP precursor liquid to the fly ash in the oscillating or stirring heater, the solid-liquid ratio of fly ash and HAP precursor liquid is 1:4 g / m...

Embodiment 3

[0052] Such as figure 1 As shown, the method for hydrothermal harmless treatment of waste incineration fly ash comprises the following steps:

[0053] A. Pre-grind the collected waste incineration fly ash to make it uniform and have a particle size below 200 μm.

[0054] B. Add 10g of egg shells (calcium carbonate substance) with the inner film removed to the ultrasonic reactor, add 7mL of industrial phosphoric acid and 93mL of tap water, react ultrasonically for 30 minutes at room temperature, and let it stand until there is no more CO 2 Bubbles are generated to obtain about 100mL of calcium phosphate salt stock solution, and then 100mL of 0.1mol / L calcium hydroxide is added dropwise at 10mL / min during stirring, and NaOH is added to keep the pH at about 12-13, and then stirred for 1 hour to obtain 200 mL of hydroxyapatite precursor solution (HAP precursor solution).

[0055] C. Add HAP precursor liquid to the fly ash in the oscillating or stirring heater. The solid-liquid r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com