Intelligent vehicle cleaning and oil replacing system and oil replacing method

An intelligent cleaning and oiling system technology, which is applied in special distribution devices, packaging, distribution devices, etc., can solve problems such as long oil filling time, new oil pollution, waste of remaining oil, etc., and achieve stable efficiency and quality Highly efficient and accurate oil products The effect of stable quality and oil injection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

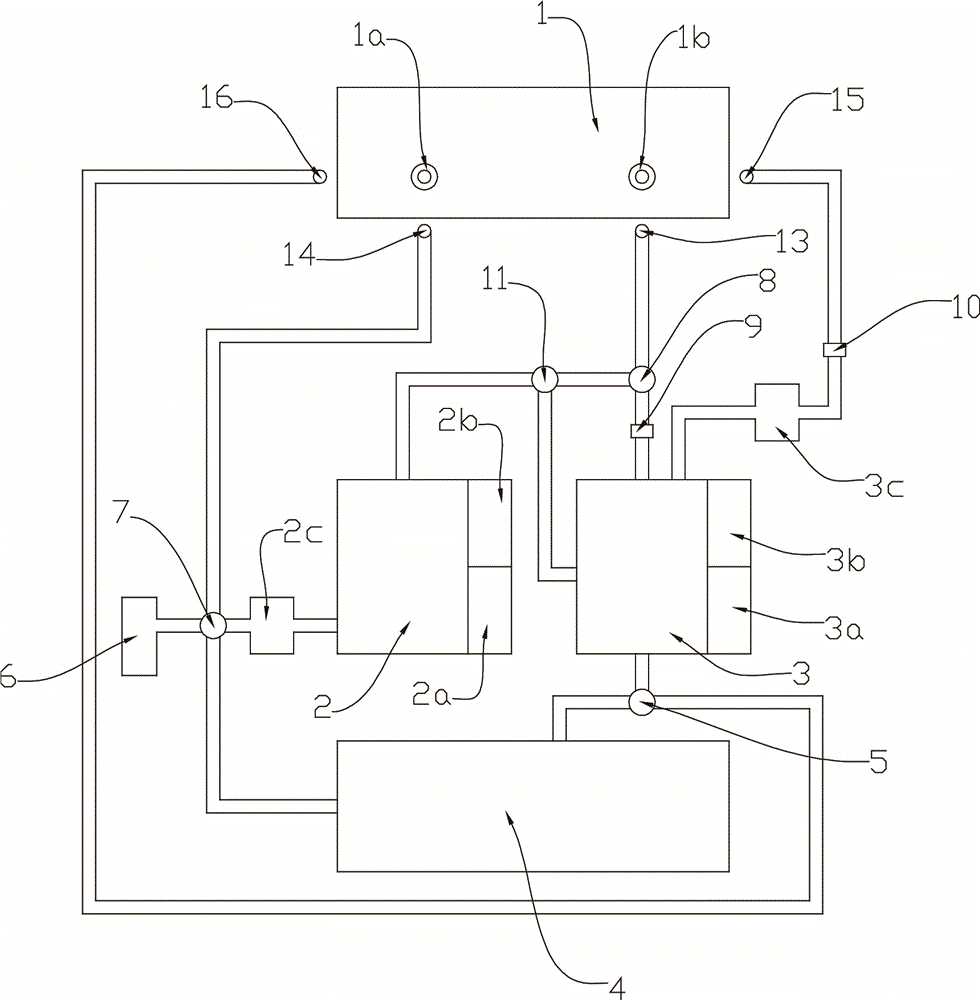

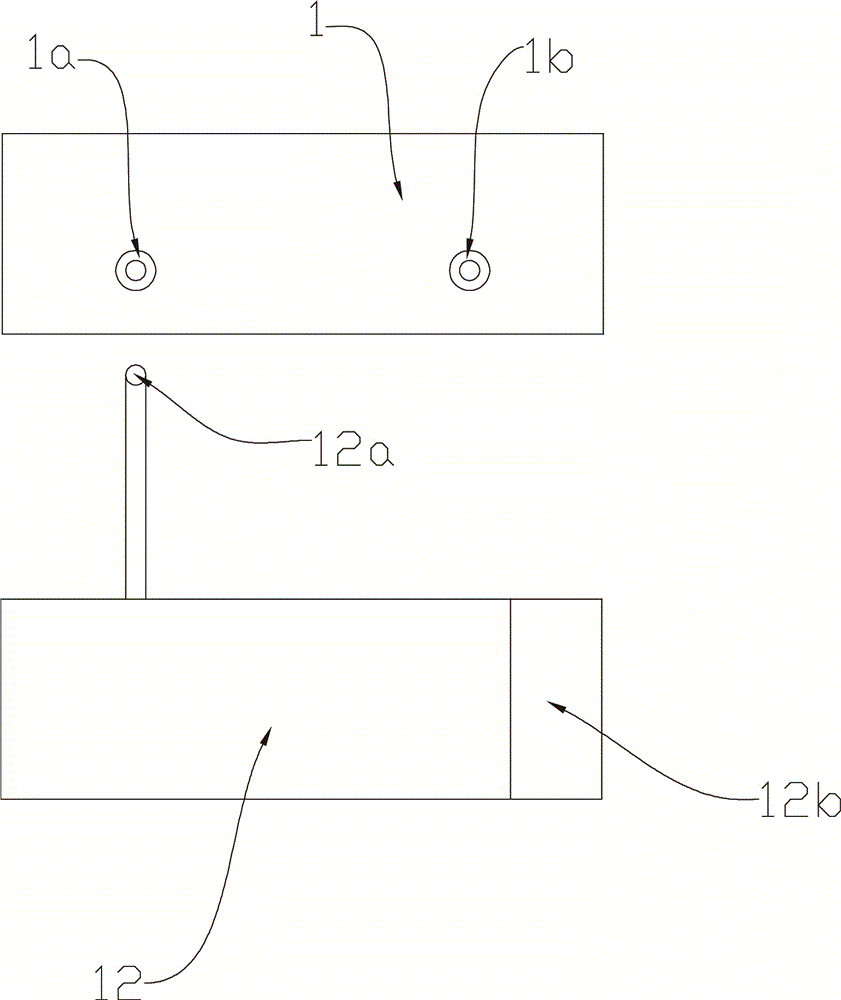

[0022] See Figure 1 to Figure 2 , a vehicle intelligent cleaning and oil change system, comprising an old fuel tank 2, a cleaning fuel tank 3, a plurality of reversing valves, a new fuel tank 12, and a waste fuel tank 4, and a first vacuum device 2a and a first pressure device are arranged in the old fuel tank 2 2b; the cleaning oil tank 3 is provided with a second vacuum device 3a and a second pressure device 3b; the old oil tank 2 is connected to the first reversing valve 7 through a pipeline, and the first reversing valve 7 is respectively connected to the waste oil tank 4 and the first oil injection joint 14, the old oil tank 2 is also connected to the second reversing valve 11 through another pipeline, and the second reversing valve 11 is respectively connected to the cleaning oil tank 3 and the third reversing valve 8, so The third reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com