Rotor structure of external rotor motor and external rotor motor

A technology of external rotor motor and rotor structure, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of increasing the risk of permanent magnet demagnetization, increasing the loss of coil winding, and increasing the current of coil winding, so as to reduce the risk of demagnetization and reduce the Coil winding loss, the effect of increasing the operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

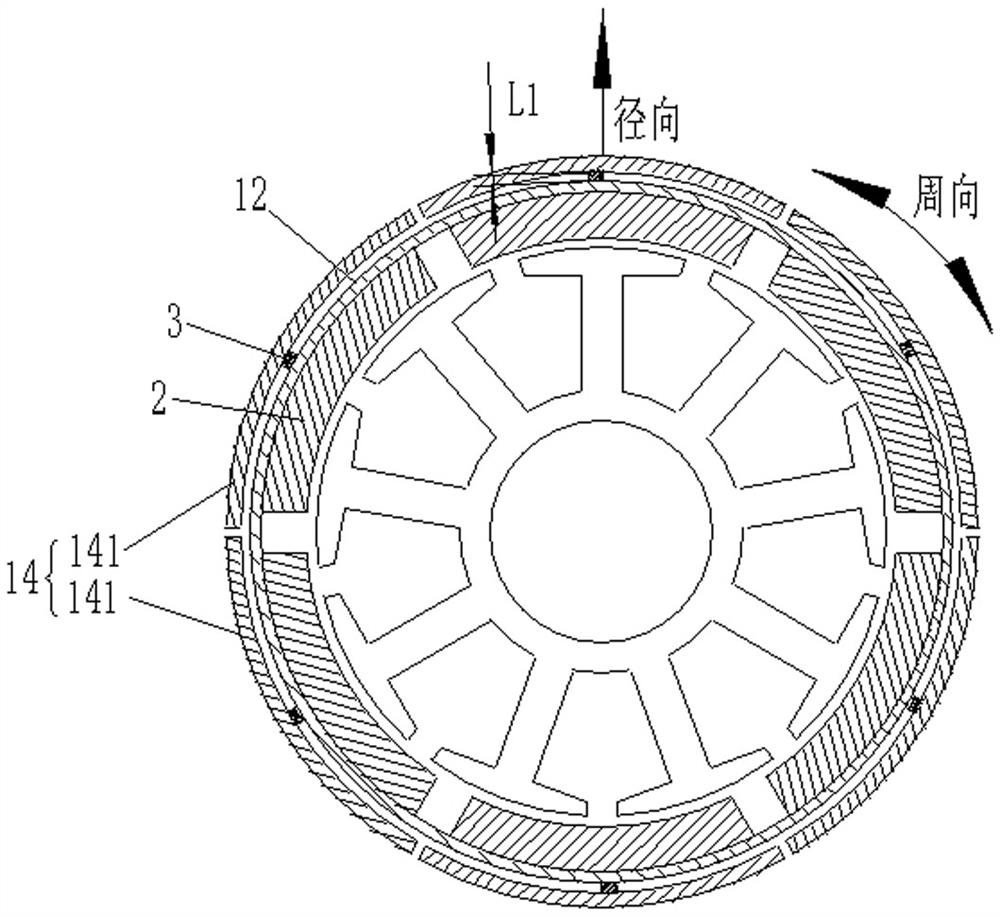

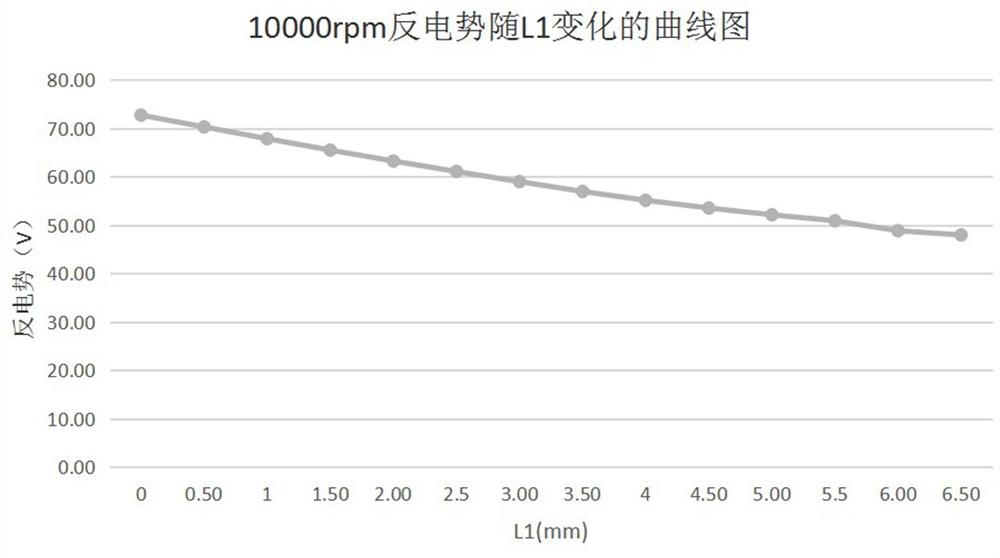

[0038] Such as figure 1 , figure 2 and image 3 As shown, this embodiment provides a rotor structure of an external rotor motor, including a rotor housing 1 and a number of permanent magnets 2. The rotor housing 1 includes an end plate 11 and a sleeve housing 12 extending from the edge of the end plate 11. The plate 11 and the sleeve shell 12 form a cavity 13, and several permanent magnets 2 are installed on the inner wall surface of the sleeve shell 12 at intervals in the circumferential direction. It is characterized in that: a movable shell 14 is installed on the outer surface of the sleeve shell 12. The casing 14 is movably installed on the outer wall of the sleeve casing 12, and the movable casing 14 is arranged radially outside the permanent magnet 2. When the rotor rotates at a speed exceeding a certain speed, the movable casing 14 moves radially to realize the effect of weakening the magnetic field and increasing the operating speed. Purpose, at high speed, without ...

Embodiment 2

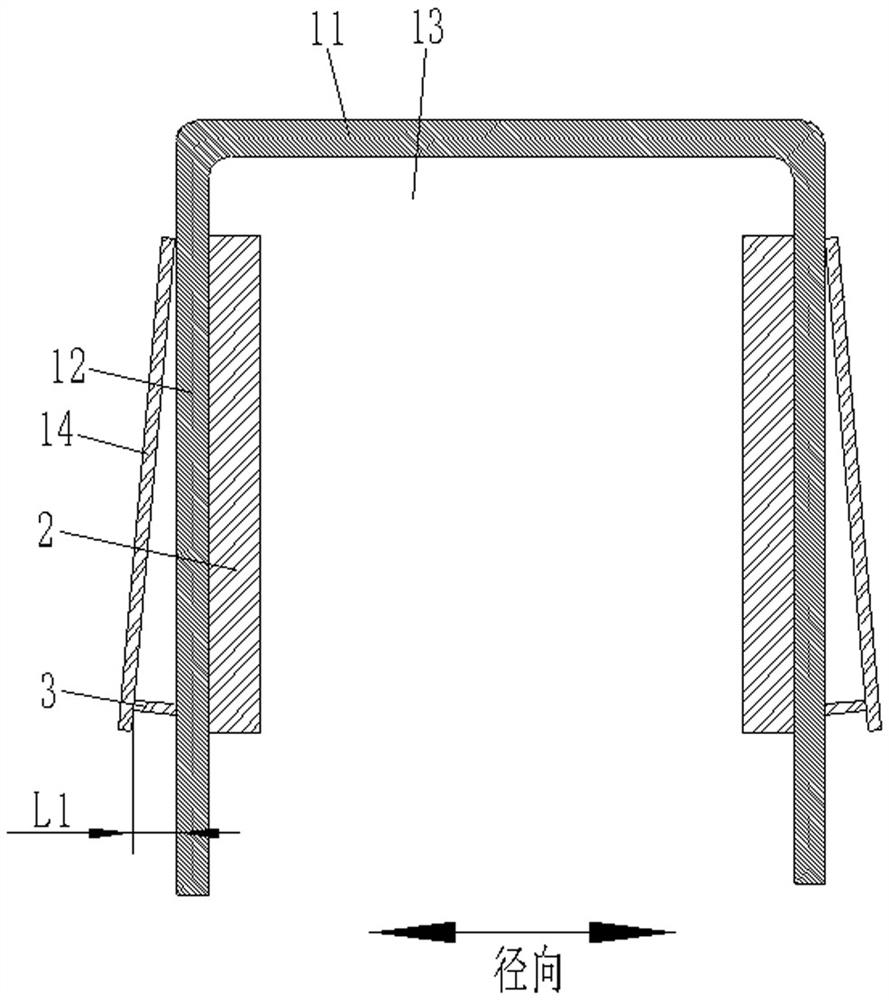

[0046] Such as Figure 4As shown, this embodiment is further improved on the basis of Embodiment 1. The above-mentioned deformable connector 3 is connected to one end of the movable monomer 141, and the other end of the movable monomer 141 is hinged on the outer wall of the sleeve shell 12 ( hinge is not shown), when the rotor rotates beyond a certain speed, one end of the movable monomer 141 does not move, and the other end swings around the hinge, the deformable connector is deformed, and the deformation distance of the deformable connector is L1, so that the movable monomer 141 Radial movement is used to achieve the purpose of weakening the magnetic field and increasing the operating speed. At high speeds, there is no need to increase the D-axis field weakening current, reduce coil winding loss, improve motor efficiency, and reduce the risk of permanent magnet demagnetization.

Embodiment 3

[0048] Such as Figure 5 As shown, this embodiment is further improved on the basis of Embodiment 1. There are two movable casings 14 above, and the two movable casings 14 are arranged at intervals along the axial direction. It consists of movable units 141 on the outer wall, and each movable unit 141 is movably installed on the outer wall of the sleeve housing 12 .

[0049] A deformable connector 3 is provided between each movable monomer 141 and the sleeve shell 12, and the inner wall surface of the movable monomer 141 and the outer wall surface of the sleeve shell 12 are respectively fixedly connected to both ends of the deformable connector 3, when When the rotor rotates over a certain speed, the deformable connector 3 is deformed, and the deformation distance of the deformable connector is L1, so that the movable monomer 141 can move radially to achieve the purpose of weakening the magnetic field and increasing the operating speed. At high speed, there is no need to incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com