Hybrid excitation double-stator switched reluctance motor

A technology of switched reluctance motor and mixed excitation, which is applied in synchronous machines, electrical components, electromechanical devices, etc., to achieve the effects of reducing core loss, increasing power density, and reducing the risk of demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

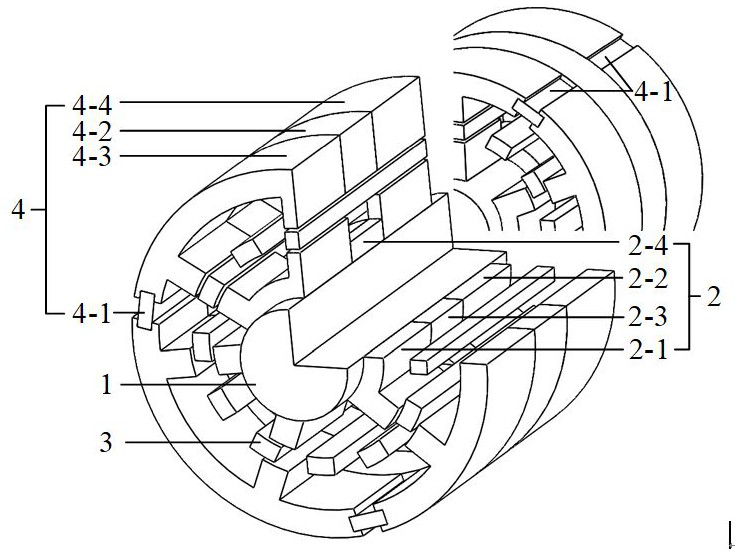

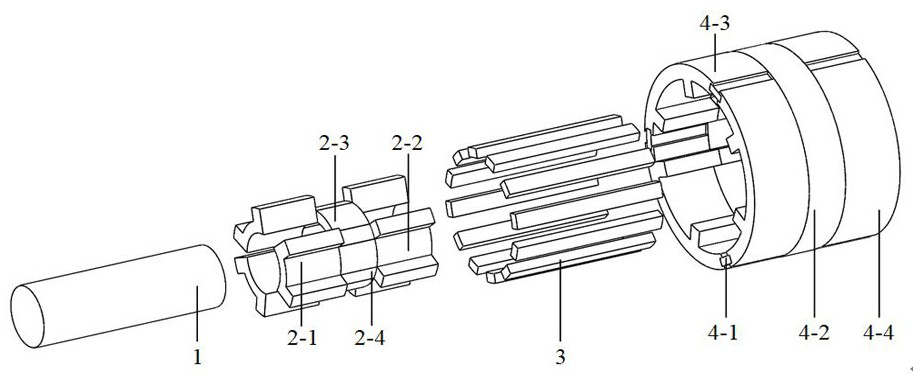

[0021] see figure 1 and figure 2 , a hybrid excitation dual-stator switched reluctance motor proposed by the present invention includes a fixed shaft 1 , a hybrid inner stator 2 , a rotor 3 , a hybrid outer stator 4 , an inner winding 5 and an outer winding 6 . In the middle is the fixed shaft 1, the hybrid inner stator 2, the rotor 3 and the hybrid outer stator 4 are coaxially nested in sequence from the inside to the outside along the radial direction, the hybrid inner stator 2 is fixedly sleeved outside the fixed shaft 1, and the hybrid inner stator 2 and the rotor 3 A radial air gap is left between them, and a radial air gap is left between the rotor 3 and the mixing outer stator 4.

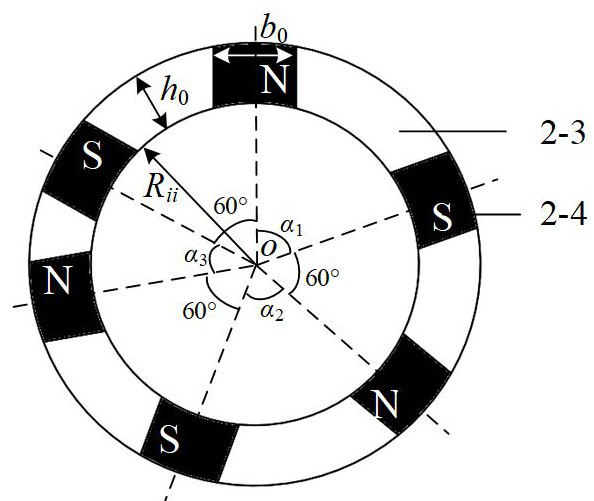

[0022] The hybrid inner stator 2 is composed of a left inner stator 2-1, a right inner stator 2-2, a magnetic isolation block 2-3 and an axially magnetized inner stator permanent magnet 2-4. recombine image 3 As shown, the magnetic isolation blocks 2-3 and the inner stator permanent magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com