Surface-mounted permanent magnet motor rotor and motor

A permanent magnet motor, surface technology, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electromechanical devices, etc., can solve the problems of increasing the length of the stator and rotor air gap, reducing the performance of the motor, increasing the weight of the motor, etc. The effect of equivalent air gap length, improving utilization, and reducing motor weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

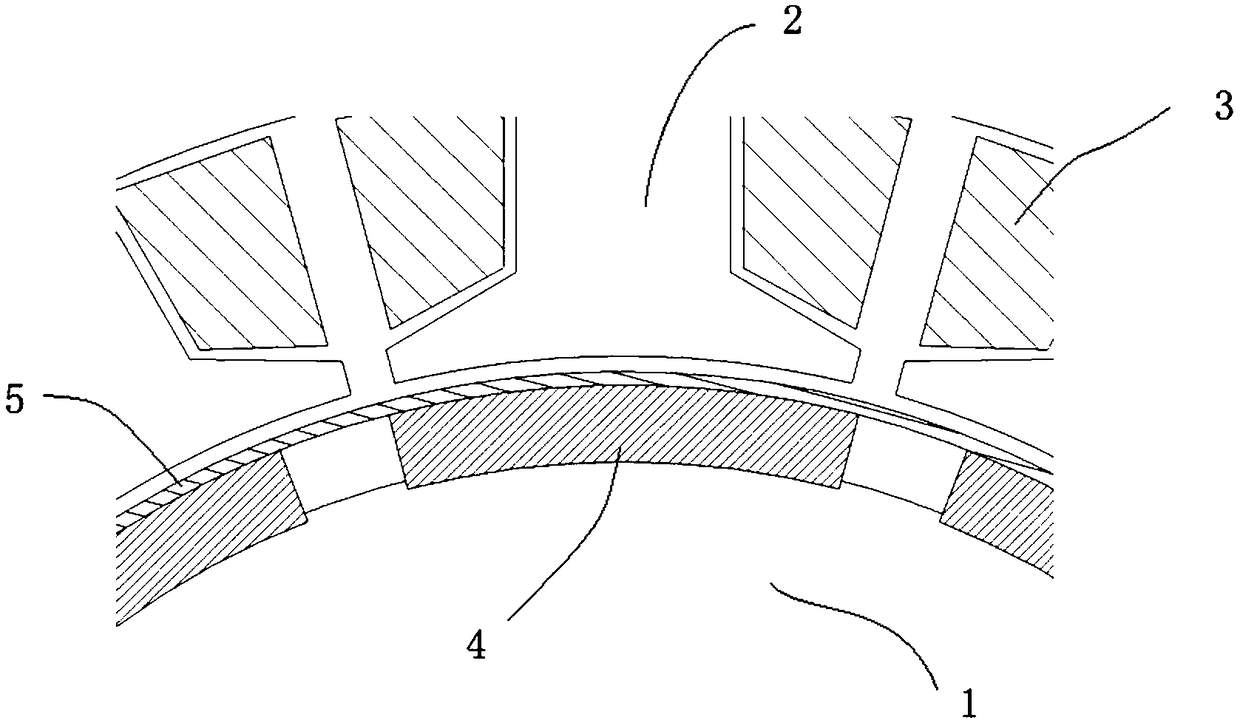

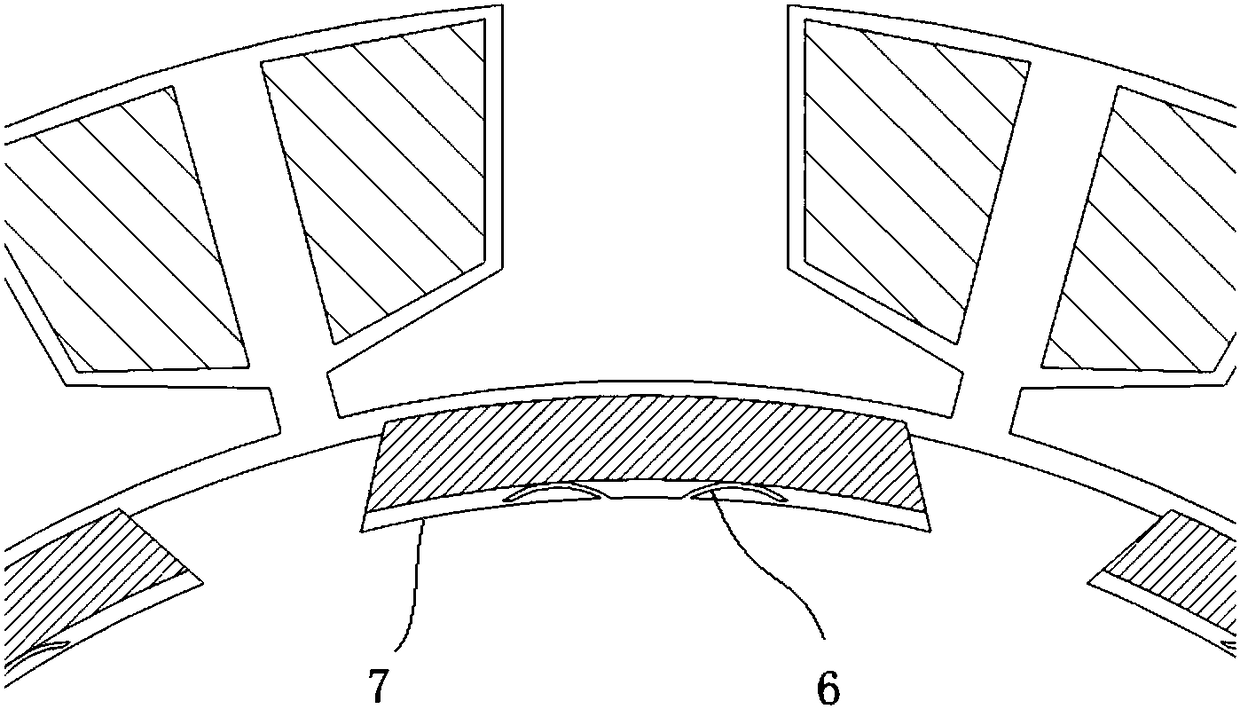

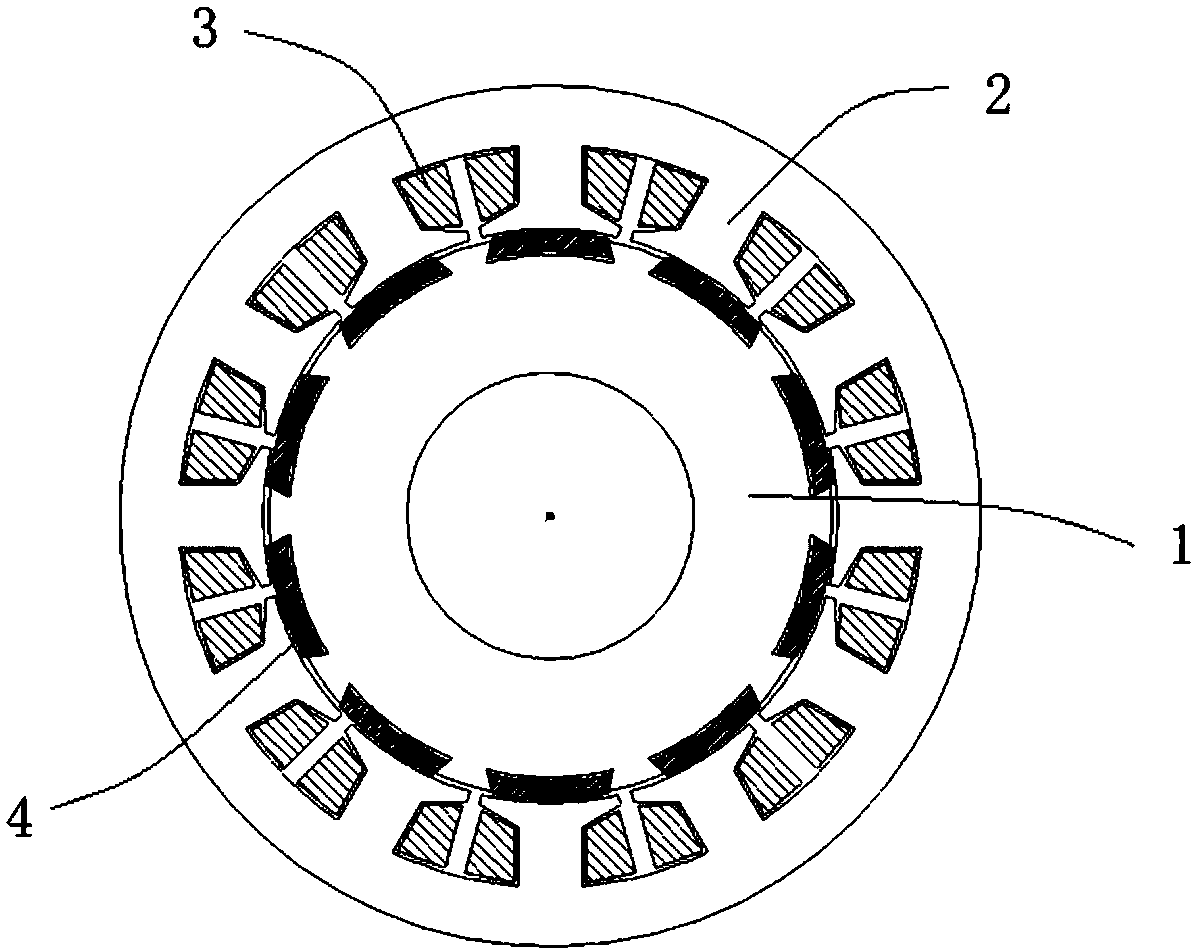

[0026] figure 2 It is a working diagram of the elastic sheet in this embodiment, image 3 It is a sectional view of the surface permanent magnet motor of this embodiment. The rotor of the surface permanent magnet motor in this embodiment includes a rotor body, the outer surface of the rotor body has a permanent magnet groove configured with permanent magnets 4, the permanent magnet groove adopts a dovetail groove structure, and more than one groove with the same width is left on the bottom edge of the permanent magnet groove. The elastic sheet 6 is integrally formed with the permanent magnet slot, one end is connected to the bottom edge 7 of the permanent magnet slot, and the other end is disconnected from the bottom edge of the permanent magnet slot to be in a freely movable state.

[0027] The elastic pieces 6 are arc-shaped, and the elastic pieces 6 are arranged side by side, and the directions of the free ends of every two adjacent elastic pieces 6 are opposite.

[0028...

Embodiment approach 2

[0031] Figure 5 It is a working schematic diagram of the elastic sheet in this embodiment. In this embodiment, the elastic piece 6 is polygonal, and preferably adopts a trapezoidal structure, wherein the top edge of the trapezoid is attached to the bottom of the permanent magnet 4 .

[0032] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment approach 3

[0034] like Image 6 As shown, the permanent magnet slots in this embodiment adopt T-shaped slots, and other structures are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com