Primary and secondary yoke-free permanent-magnetic linear synchronous motor with double-side secondary structure

A permanent magnet linear synchronization, secondary structure technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problem of low thrust density, achieve increased thrust density, good dynamic response performance, armature magnetomotive force added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

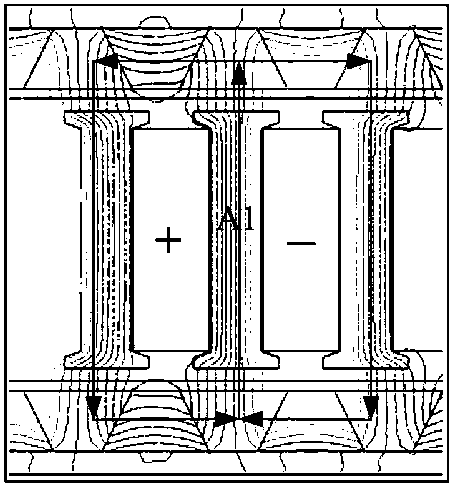

[0017] Specific implementation mode one: combine figure 1 Describe this embodiment, the permanent magnet linear synchronous motor with primary and secondary yokeless bilateral secondary structures described in this embodiment, it includes a primary 1 and a secondary 2, and the secondary 2 includes an upper secondary 21 and a lower secondary 22 , the upper secondary 21 is set above the primary 1, and the next secondary 22 is set below the primary 1; the primary 1 includes 2M+1 magnetic teeth 11 and M coils 12, and the 2M+1 magnetic teeth 11 are from the left Arranged side by side in parallel to the right, and 2M+1 magnetic teeth 11 are numbered from left to right as No. 1 magnetic tooth, No. 2 magnetic tooth, No. 3 magnetic tooth, ..., 2m+1 No. The magnetic tooth, the mth magnetic permeable tooth 11 is covered with a coil 12, the said M is a natural number, the number is 1, 2, 3...m, and the said m is a sequence of natural numbers 1, 2, 3.... m. The positive and negative sign...

specific Embodiment approach 2

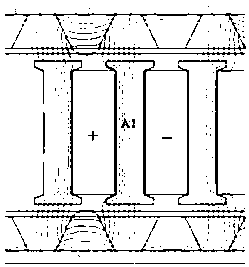

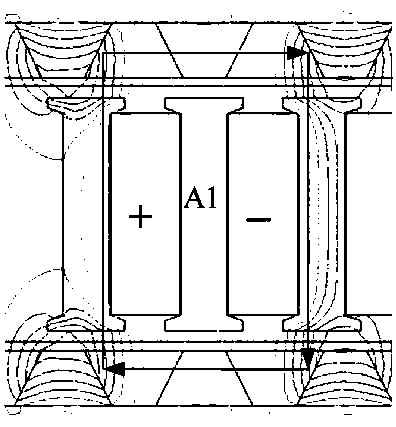

[0019] Specific implementation mode two: combination figure 2 Describe this embodiment, the permanent magnet linear synchronous motor with primary and secondary yokeless bilateral secondary structures described in this embodiment, it includes a primary 1 and a secondary 2, and the secondary 2 includes an upper secondary 21 and a lower secondary 22 , the upper secondary 21 is set above the primary 1, and the next secondary 22 is set below the primary 1; the primary 1 includes 2M+1 magnetic conductive teeth 11, 2M coils 12 and 2M brackets 13, 2M+1 conductive The magnetic teeth 11 are arranged side by side in parallel from left to right, and the 2M+1 magnetic teeth 11 are numbered from left to right as No. 1 magnetic tooth, No. 2 magnetic tooth, No. 3 magnetic tooth, ..., No. 2m+1 magnetic tooth, two coils 12 are set on the mth magnetic tooth 11, all the upper coils belong to a coil group, and all the lower coils belong to a coil group, the two coil groups can be connected in se...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, the magnetically conductive teeth 11 of the permanent magnet linear synchronous motor with primary and secondary yokeless bilateral secondary structures described in this embodiment are composed of a plurality of silicon steel sheets superimposed. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com