Grinding unit for high speed train and preparation method of grinding unit

A technology for high-speed EMUs and abrasives, which can be used in vehicle maintenance, vehicle cleaning, metal processing equipment, etc., and can solve the problems that the application is not fully mature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

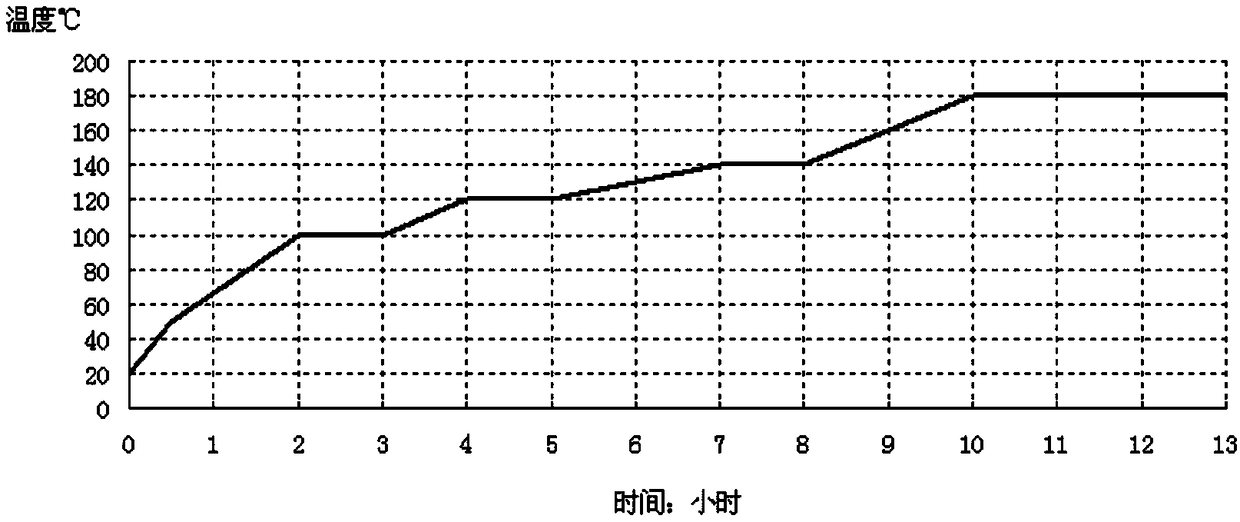

[0054] The invention provides a method for preparing a grinding wheel for high-speed EMUs, which includes the following steps: the selected raw materials are weighed, mixed, steel back surface treated, glue sprayed, hot-pressed and heat-treated according to the ratio, and the specific steps are as follows :

[0055] 1) Weighing:

[0056] According to the proportion of the raw material of the grinding sub, use an electronic scale with a suitable range and precision to accurately weigh the required amount of material; put different raw materials in different marked material boxes and make records for easy traceability.

[0057] 2) Mixing:

[0058] a) The present invention uses a rake type mixer for mixing, which can solve the problem of mixing uniformity of most asbestos-free mineral fibers and organic fibers with fillers, resins, and powdered rubber.

[0059] b) Put the prepared materials into the mixer, close the feed port; set the coulter to run for 20-25 minutes, and the h...

Embodiment 1

[0082] Embodiment 1, a kind of grinder for high-speed EMU and preparation method thereof

[0083] A grinding wheel for a high-speed EMU, the grinding wheel is composed of a steel back and a friction material, and the friction material includes the following raw materials and weight ratios, as shown in Table 1.

[0084] Table 1. Raw materials and weight ratio of friction materials

[0085] serial number

Weight ratio

1

Phenolic Resin

10%

2

Reduced iron powder

52%

3

4.9%

4

Aluminum oxide

7%

5

17%

6

4%

7

4%

8

1%

9

0.1%

[0086] The preparation method of a grinding wheel for a high-speed EMU includes the following steps: the selected raw materials are weighed according to the weight ratio, mixed, steel back surface treatment, glue sprayin...

Embodiment 2

[0099] Embodiment 2, a kind of grinder for high-speed EMU and preparation method thereof

[0100] A grinding wheel for a high-speed EMU, the grinding wheel is composed of a steel back and a friction material, and the friction material includes the following raw materials and weight ratios, as shown in Table 2.

[0101] Table 2. Raw materials and weight ratios of friction materials

[0102] serial number

Weight ratio

1

Phenolic Resin

9%

2

powdered nitrile rubber

4%

3

Reduced iron powder

58%

4

2.5%

5

Aluminum oxide

4%

6

steel fiber

16.5%

7

3.5%

8

Aramid fiber

2%

9

0.5%

[0103] The preparation method of a grinding wheel for a high-speed EMU includes the following steps: the selected raw materials are weighed according to the weight ratio, mixed, steel back surface treatment, glue spraying, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com