Friction particle, friction material and friction goods

A technology of friction particles and friction materials, applied in other chemical processes, chemical instruments and methods, etc., can solve environmental pollution and other problems, and achieve the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

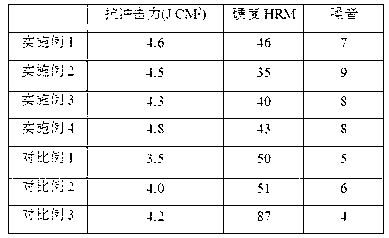

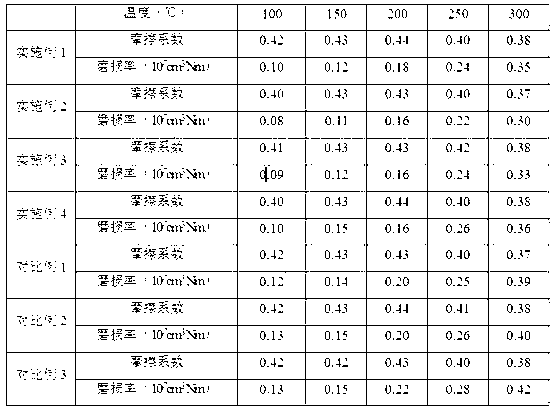

Examples

Embodiment 1

[0024] This embodiment provides a friction particle, which can be prepared by the following method:

[0025] 1) Material preparation: According to grinding dust: 73 parts, phenolic resin: 1 part, liquid nitrile rubber: 15 parts, expanded graphite: 2 parts, molybdenum sulfide: 1 part, expanded perlite powder: 7 parts, brass powder: 1 part, choose grinding dust, phenolic resin, liquid nitrile rubber, expanded graphite, molybdenum sulfide, expanded perlite powder, and brass powder;

[0026] 2) Mix the above materials evenly according to the proportion, and then put the mixture into the internal mixer for banburying for 5 minutes. The banburying temperature is 80°C. After cooling the blocks after banburying, break them into 4-40 mesh Particles, that is, friction particles.

[0027] This embodiment also provides a friction material, which includes a binder, a second reinforcing material, a second friction modifier, and the friction particles prepared by the above method. It can b...

Embodiment 2

[0030] This embodiment provides a friction particle, which can be prepared by the following method:

[0031] 1) Material preparation: according to grinding dust: 55 parts, phenolic resin: 3 parts, liquid nitrile rubber: 20 parts, expanded graphite: 7 parts, molybdenum sulfide: 4 parts, expanded perlite powder: 7 parts, brass powder: 4 parts, choose grinding dust, phenolic resin, liquid nitrile rubber, expanded graphite, molybdenum sulfide, expanded perlite powder, and brass powder;

[0032] 2) Mix the above materials evenly according to the proportion, then put the mixture into the internal mixer and banbury for 8 minutes. The banbury temperature is 100°C. After cooling the mass after banbury, break it into 4-40 mesh Particles, that is, friction particles.

[0033] This embodiment also provides a friction material, which includes a binder, a second reinforcing material, a second friction modifier, and the friction particles prepared by the above method. It can be understood ...

Embodiment 3

[0036] This embodiment provides a friction particle, which can be prepared by the following method:

[0037] 1) Material preparation: according to grinding dust: 65 parts, phenolic resin: 2 parts, liquid nitrile rubber: 18 parts, expanded graphite: 5 parts, molybdenum sulfide: 4 parts, expanded perlite powder: 5 parts, brass powder: 1 part, choose grinding dust, phenolic resin, liquid nitrile rubber, expanded graphite, molybdenum sulfide, expanded perlite powder, and brass powder;

[0038] 2) Mix the above materials evenly according to the proportion, and then put the mixture into the internal mixer for banburying for 7 minutes. The banburying temperature is 90°C. After cooling the mass after banburying, break it into 4-40 mesh Particles, that is, friction particles.

[0039] This embodiment also provides a friction material, which includes a binder, a second reinforcing material, a second friction modifier, and the friction particles prepared by the above method. It can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com