Guide rail sliding block device and machining technology thereof

A guide rail slider, processing technology, applied in bearings, linear motion bearings, bearing components, etc., can solve the problems of poor stability, high noise, poor structural design of bearings and guide rails, etc., to achieve good stability and service life. The effect of long, feasible processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

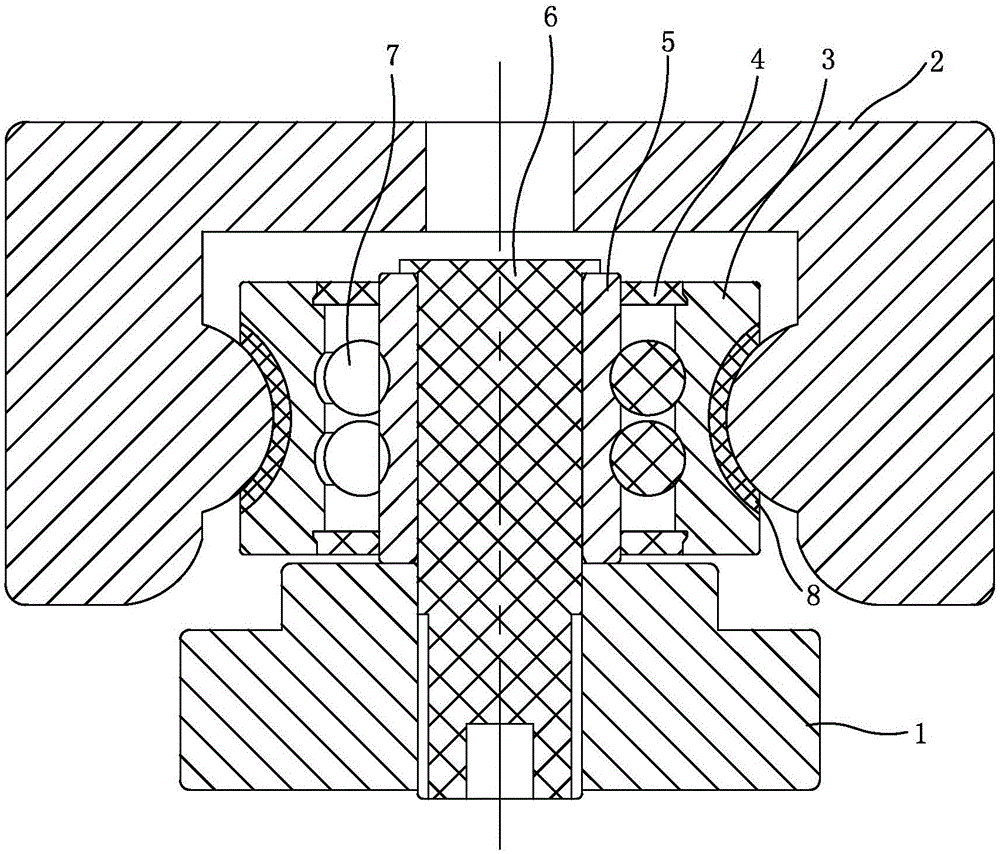

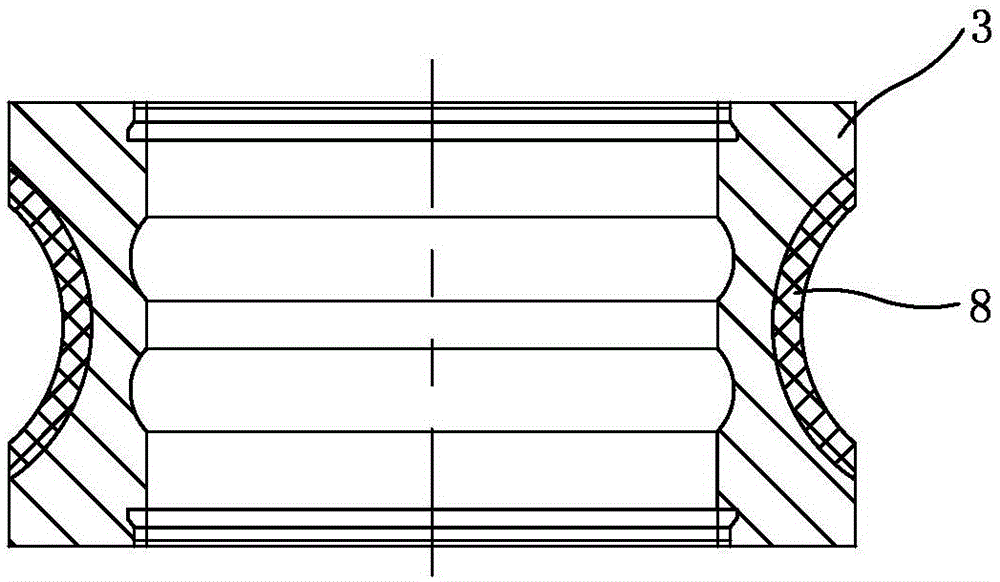

[0016] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. The guide rail slider device includes a slider 1, a guide rail 2 and a slider bearing. The slider bearing includes an outer ring 3, a dust cover 4, an inner ring 5, a steel ball 7 and a cage, and a steel ball is arranged between the inner ring and the outer ring. And the cage, the ring-shaped gap on both sides between the inner ring and the outer ring is provided with a dust cover, the slider bearing is connected with the slider through the screw 6, and the outer ring of the slider bearing passes through the chute of the outer ring on the slide of the guide rail. slide on the rail. The chute of the outer ring is provided with a glue coating layer 8, which is integrally formed with polyurethane material and the outer ring. The main processing process of the outer ring rubber coating layer is: heat treatment → sandblasting → milling groove → putting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com