Double-row multi-roller type modular current-receiving device for electric locomotive

A technology of electric locomotives and current receiving devices, which is applied to electric vehicles, circuits, collectors, etc., to achieve the effects of shortening service life, avoiding Joule heat, and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

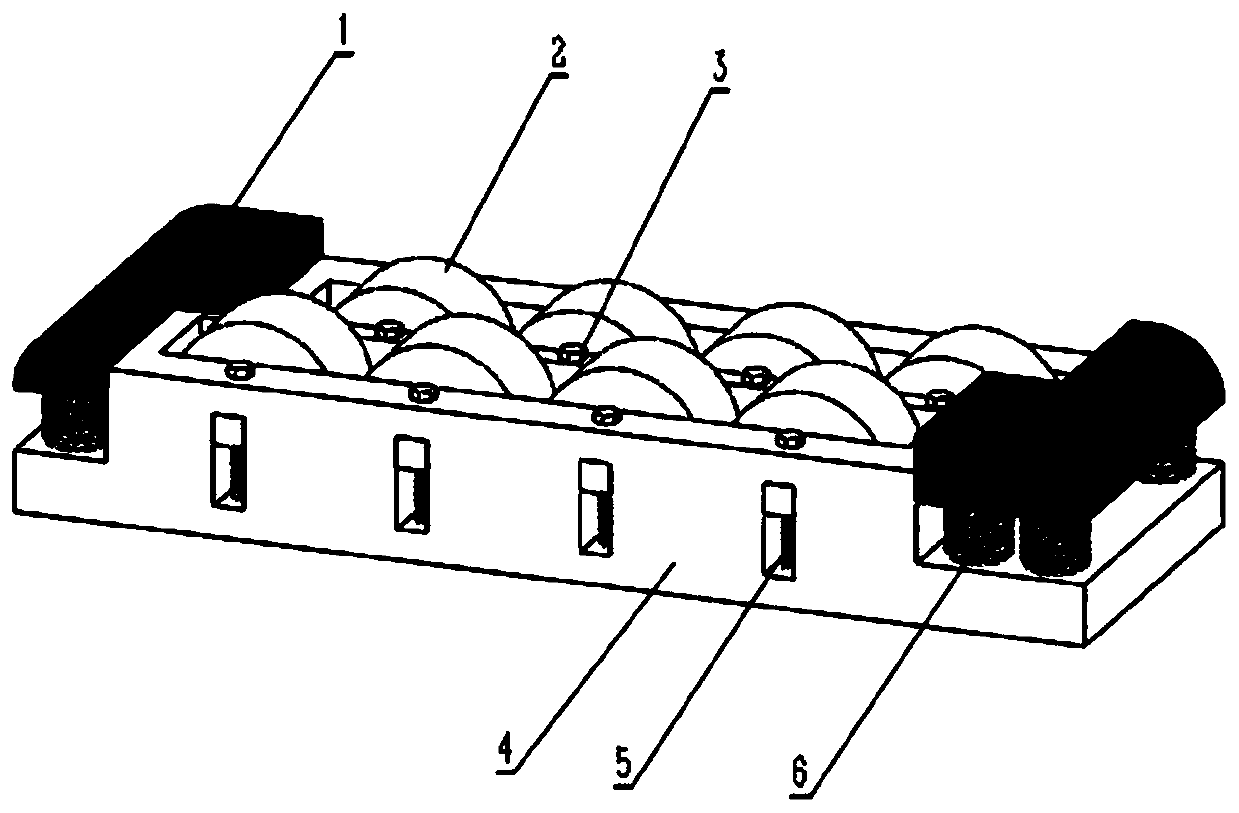

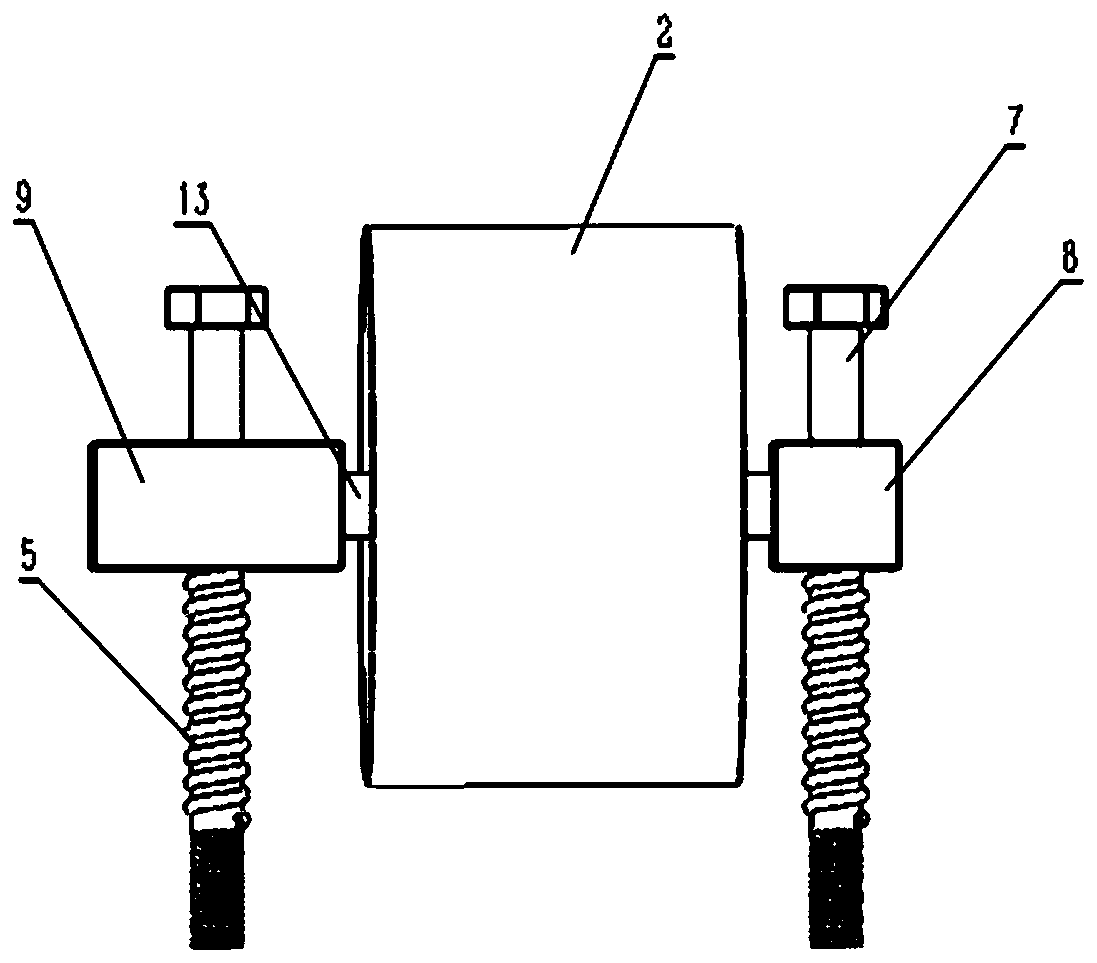

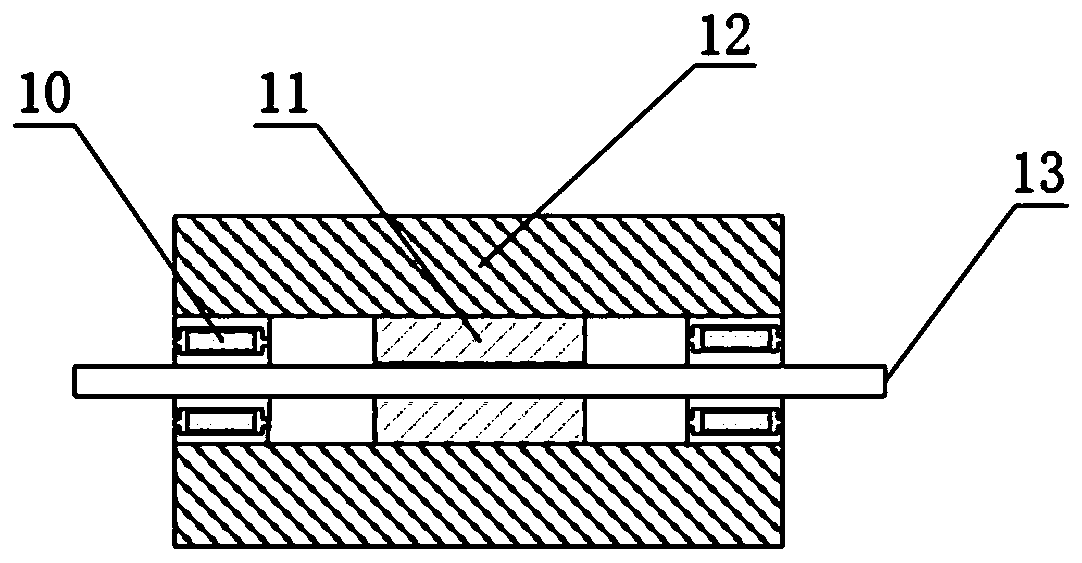

[0025] In the drawings: 1—(arc) pure carbon slider, 2—metal roller, 3—roller bracket (mainly composed of two insulating columns), 4—rectangular frame or rectangular frame, 5—compression spring, 6— Spring, 7—insulating column (cylindrical, two), 8—insulating block (with holes on it), 9—another insulating block (with holes on it), 10—insulating bearing, 11—current receiving brush, 12—roller metal shell, 13—metal shaft, 14—contact rail, 15—contact rail protective cover.

[0026] figure 1 figure 2 As shown, the double-row multi-roller modular current receiving device for the new type electric locomotive, the rectangular bottom plate of the insulating base 4 is evenly arranged along its long side direction with two rollers for rolling contact with the bottom surface of the contact rail 14 to receive electricity. Rows of metal rollers 2, each row has a plurality of metal rollers 2, and each metal roller 2 is arranged in the following manner: two insulating columns 7 are fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com