Preparation method for alloy sample surface wear-resisting protective layer

A protective layer and sample technology, applied in the direction of surface reaction electrolytic coating, coating, anodizing, etc., can solve the problem of reducing the lubricating ability and service life of the lubricating film, reducing the friction coefficient, lubricating phase particles and friction surface of aluminum alloy parts The pores cannot achieve the mutual anti-friction effect, etc., to achieve the effect of improving the lubricating performance, reducing the corrosion, and reducing the friction coefficient value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The surface of the aluminum alloy is polished, and the surface roughness is Ra0.8; after alkali washing, pickling and neutralization, the surface is dried to keep the surface clean.

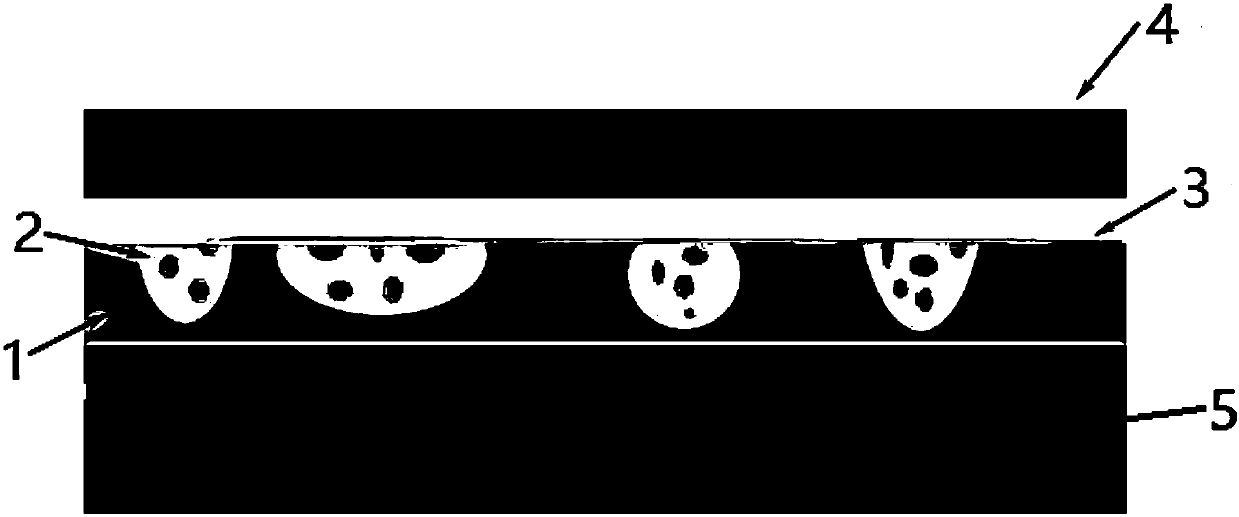

[0044] Put the prepared sample into the electrolyte of the silicate system during micro-arc oxidation. The composition and concentration of the electrolyte are: 8g / LNaSiO 3 , 2g / LCH 3 COOHNa, 3g / LNa 5 P 3 o 10 , PH: 10~11 Put the dried aluminum alloy sample into the electrolyte, adopt the constant current method, the positive and negative current density is 30A / dm 2 , the frequency is 500Hz, and the time is 20min. After micro-arc oxidation treatment, the average pore diameter of the aluminum alloy surface is 3 μm, and the pores between 1 and 5 μm account for 35% of all pores.

[0045] Dissolve 3g / l polyimide powder completely in the ethanol solution, then add molybdenum disulfide powder with an average particle size of 1 μm into the PI / ethanol solution to make the solid phase content ...

Embodiment 2

[0061] The surface of the aluminum alloy is polished, and the surface roughness is Ra0.8; after alkali washing, pickling and neutralization, the surface is dried to keep the surface clean.

[0062] Put the prepared sample into the electrolyte of the silicate system during micro-arc oxidation. The composition and concentration of the electrolyte are: 8g / LNaSiO 3 , 2g / LCH 3 COOHNa, 3g / LNa 5 P 3 o 10 , PH: 10~11 Put the dried aluminum alloy sample into the electrolyte, adopt the constant current method, the positive and negative current density is 30A / dm 2 , the frequency is 500Hz, and the time is 25min. After micro-arc oxidation treatment, the average pore diameter of the aluminum alloy surface is 3 μm, and the pores between 1 and 5 μm account for about 30% of all pores.

[0063] Dissolve 3g / l polyimide powder completely in the ethanol solution, then add graphite powder with an average particle size of 0.7 μm into the PI / ethanol solution to make the solid phase content reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com