Patents

Literature

43results about How to "Achieve self-lubricating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

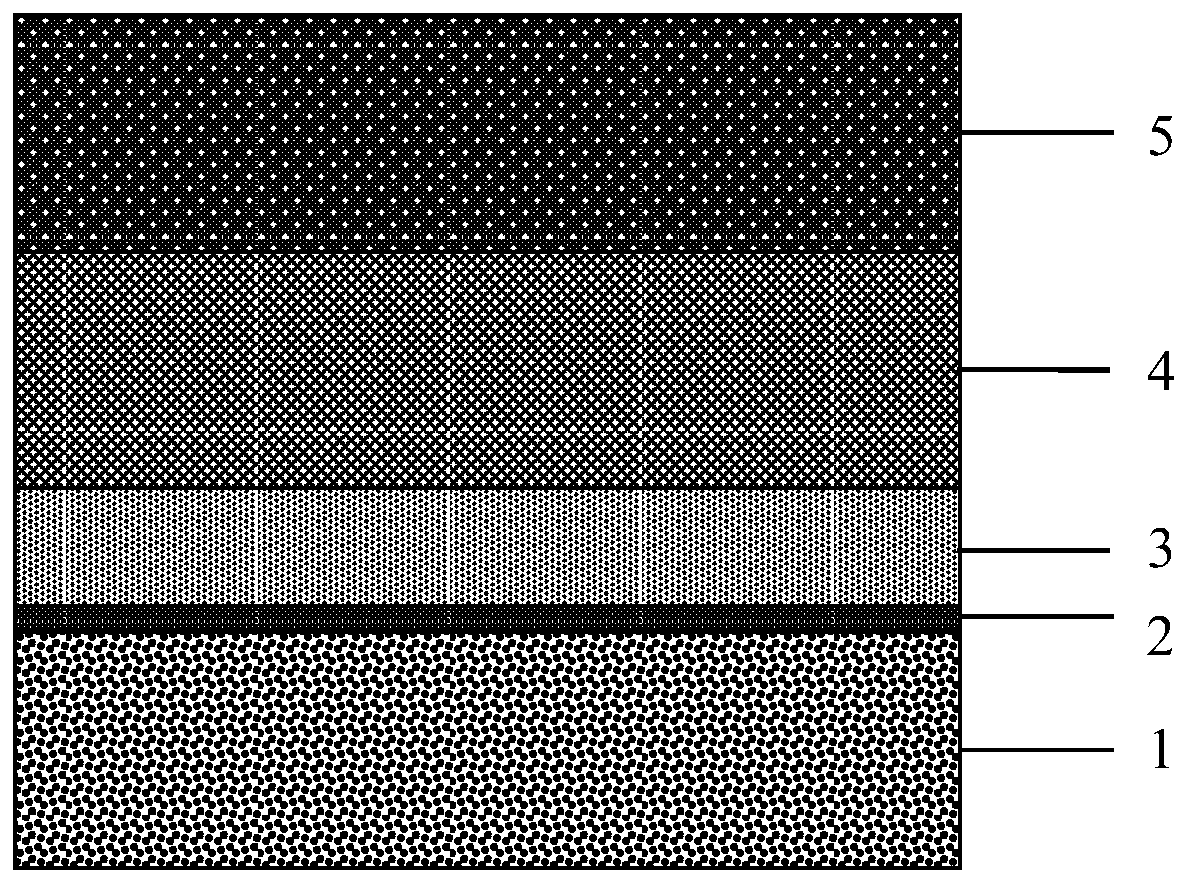

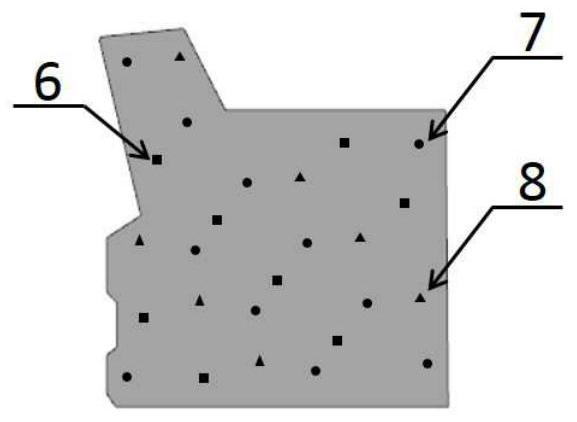

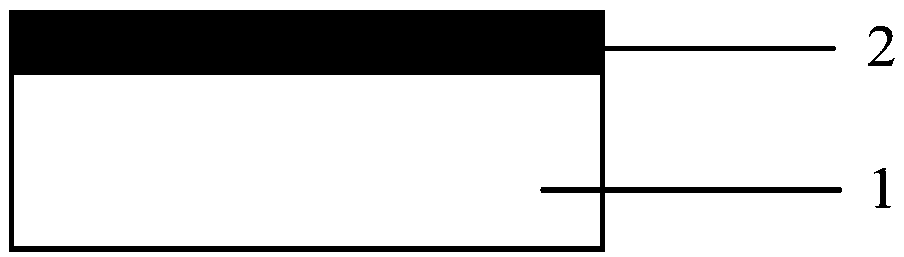

Self-lubricating ceramic composite material with biomimetic structure and preparation method thereof

ActiveCN102092164AStable lubricationAvoid adverse effectsCeramic layered productsMolybdenum disulfideGraphite

The invention discloses a self-lubricating ceramic composite material with a biomimetic structure and a preparation method thereof. The composite material has a structure which is alternately laminated by ceramic layers and lubricating layers, wherein the ceramic layer is ZrO2, Al2O3, or ZrO2-Al2O3, and the lubricating layer is made of graphite, molybdenum disulfide, or hexagonal boron nitride. The composite material has excellent friction and abrasion performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

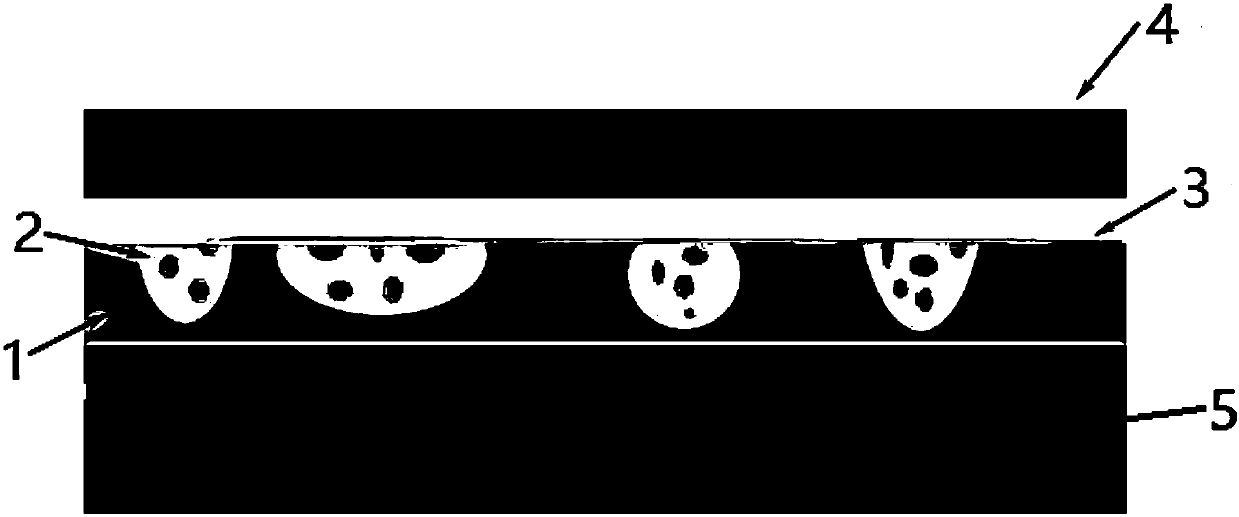

Preparation method for alloy sample surface wear-resisting protective layer

InactiveCN108018589AEffective lubricationGood self-lubricating performanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a preparation method for an alloy sample surface wear-resisting protective layer. Firstly, an alloy sample is subject to micro-arc oxidation treatment, and a multi-hole micro-arc oxidation layer is obtained on the alloy sample surface; and secondly, a sealant is applied to the alloy sample surface. According to the preparation method, through the technologies of micro-arcoxidation, sealant applying and the like, an even micro-arc oxidation layer and lubrication particle composite self-lubricating wear-resistant coating is prepared on the alloy sample surface, the characteristic that micropores and lubrication particles are organically bonded is effectively used, and the antiseptic, wear-resisting and lubricating properties are greatly improved.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Seal ring special for automobile air filter

The invention discloses a special seal ring for an automobile air filter. The special seal ring for the automobile air filter is prepared from the following components in percentage by weight: 30% of butadiene-acrylonitrile rubber, 15% of natural rubber, 25% of carbon black, 10% of zinc oxide powder, 3% of softener dioctyl-phthalate, 1% of active agent zinc oxide, 4% of stearic acid, 2.3% of vulkacit dicumyl peroxide, 2% of sulphur powder, 2% of self-lubricating agent unsaturated fatty acid, and the balance of engine oil. The heat resistance of the seal ring is improved to 135 DEG C from 100 DEG C; the capabilities of resisting engine oil and fuel corrosion are intensified greatly; moreover, a wax-type protective layer can automatically exude from the seal ring special for the automobile air filter after the seal ring is placed at normal temperature for 15 days so as to achieve the self-lubricating effect, so that the seal ring special for the automobile air filter is very convenient to assemble, and the service life of the seal ring is also prolonged greatly.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

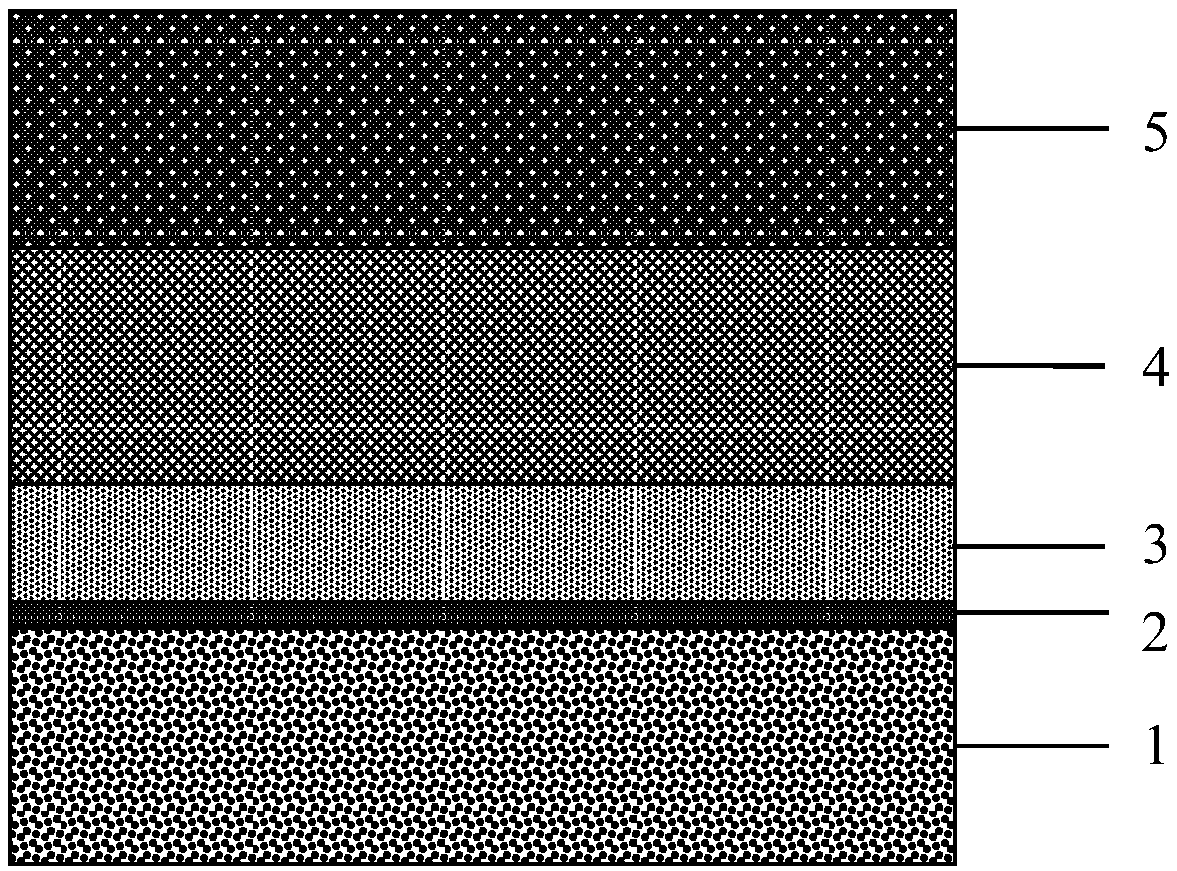

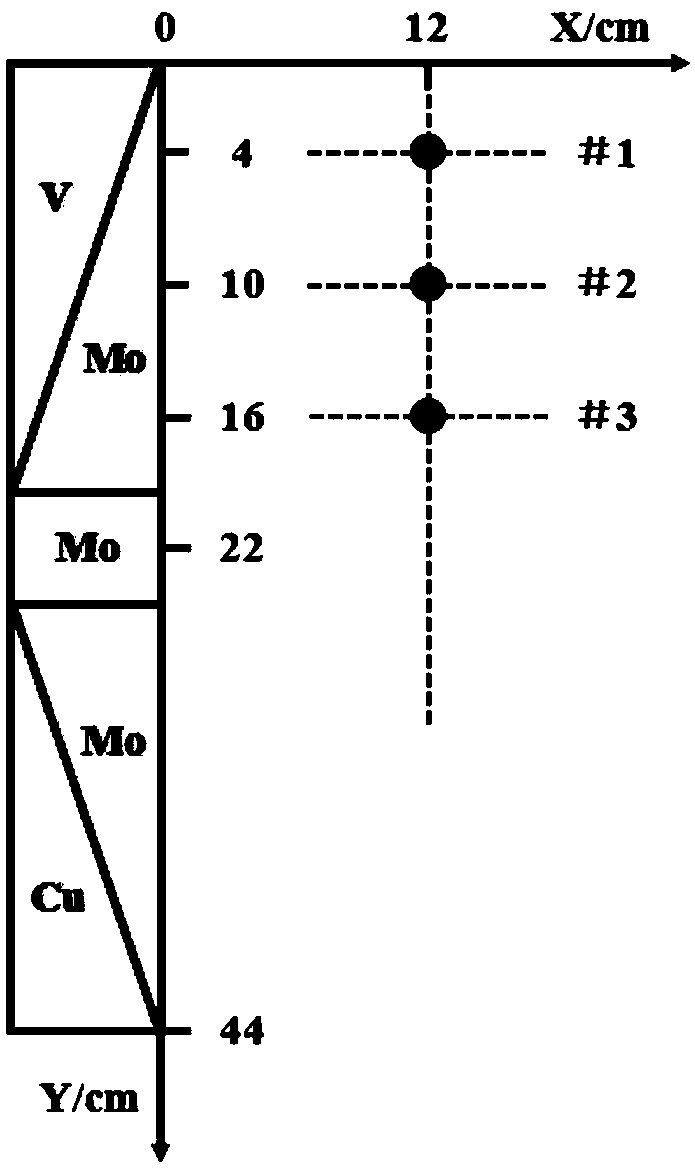

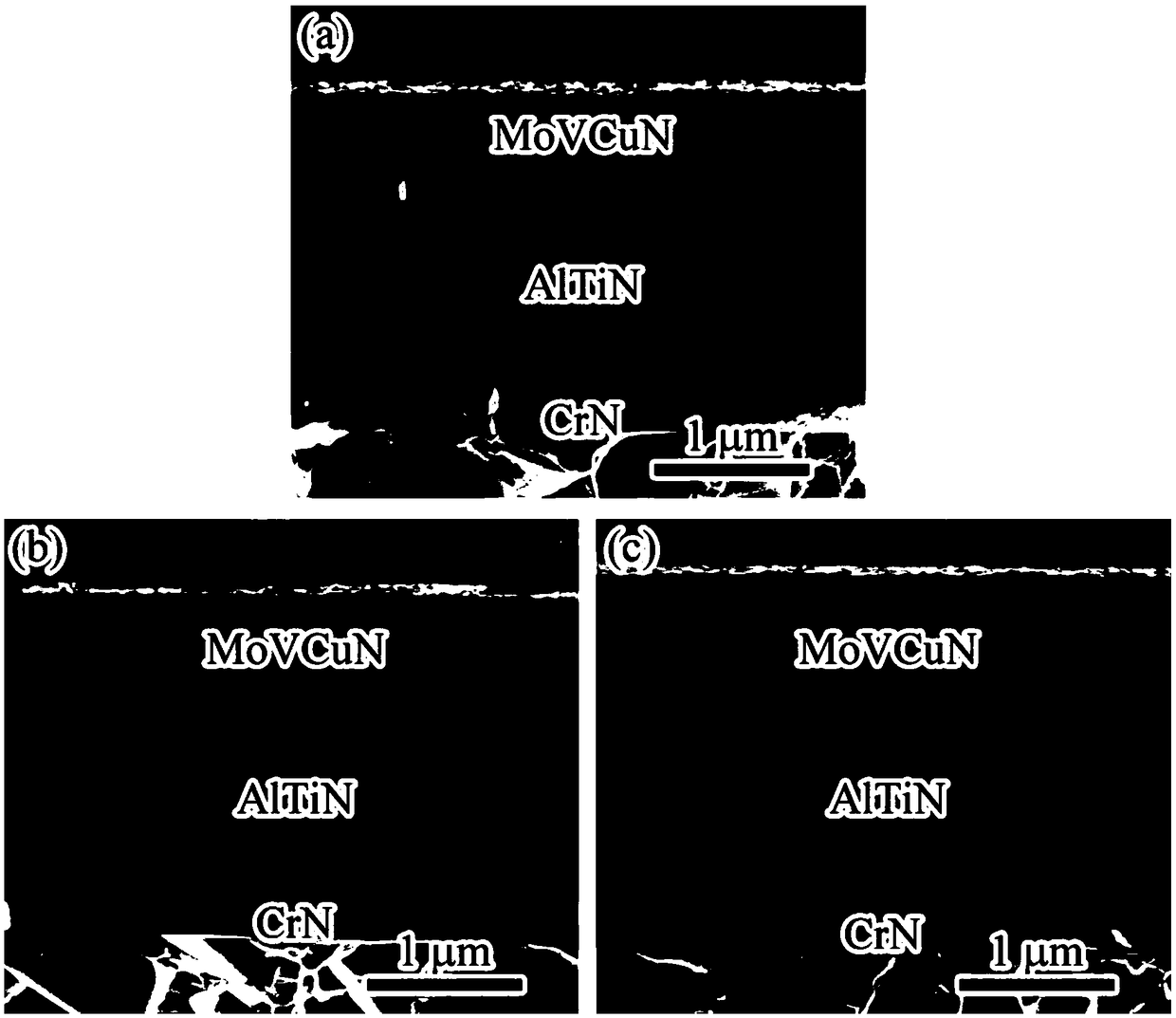

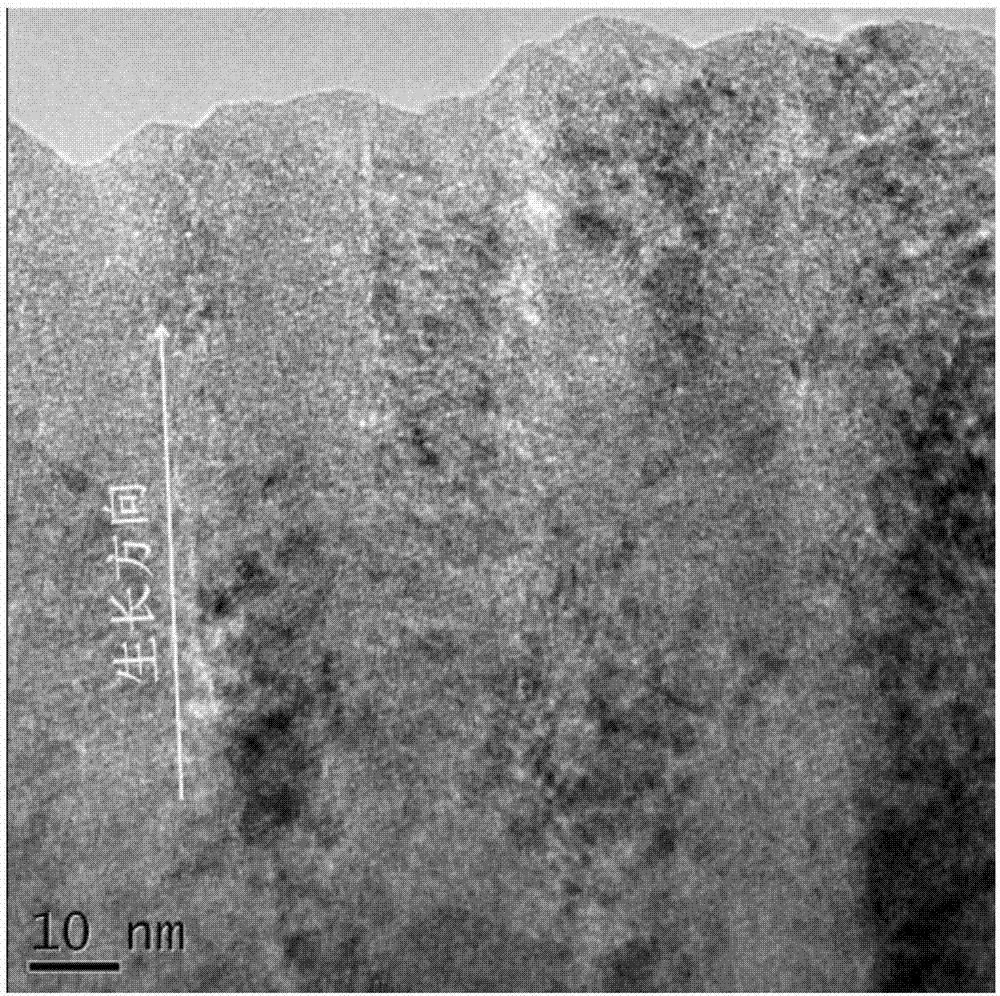

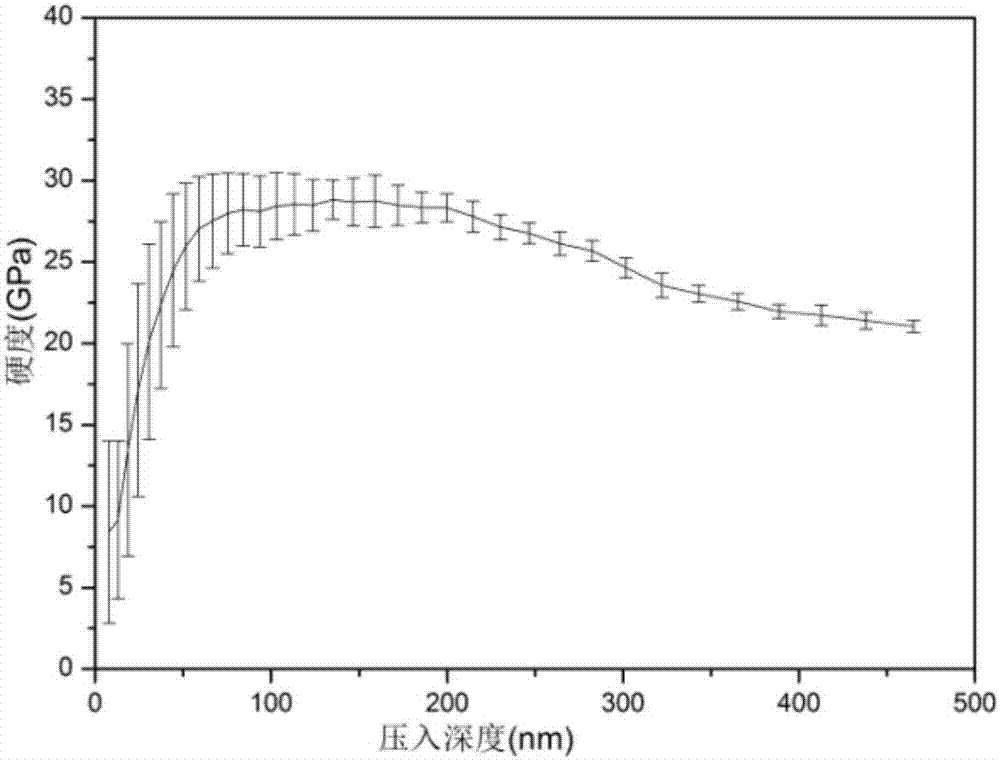

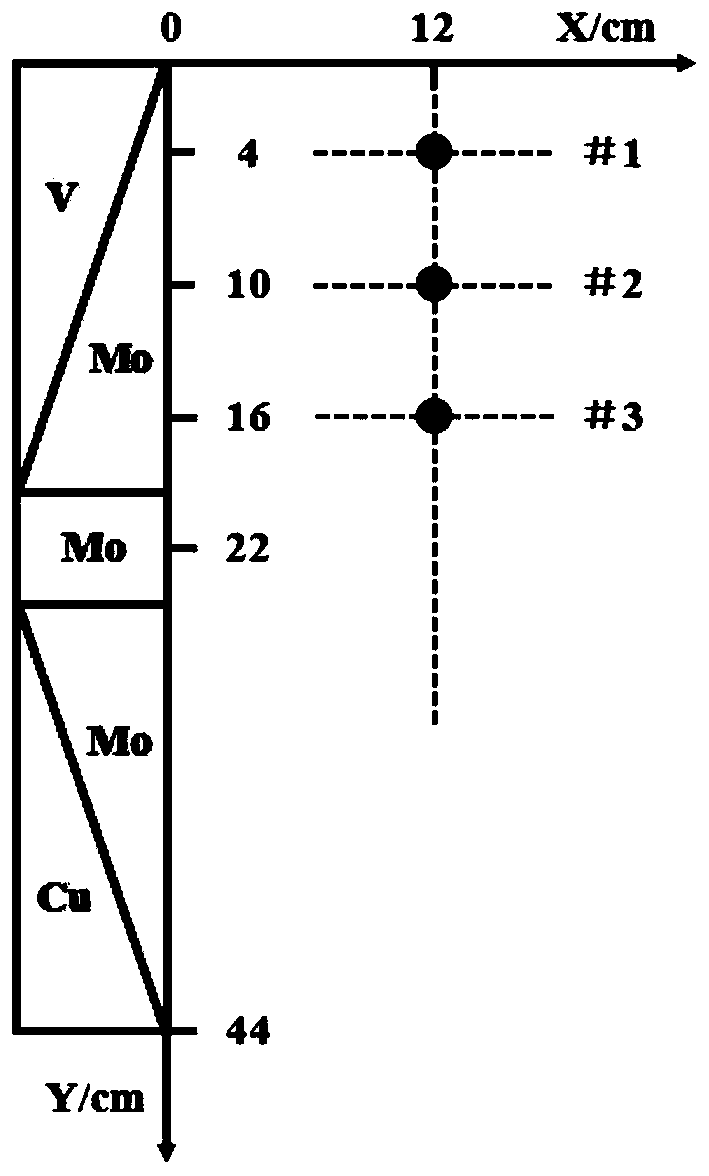

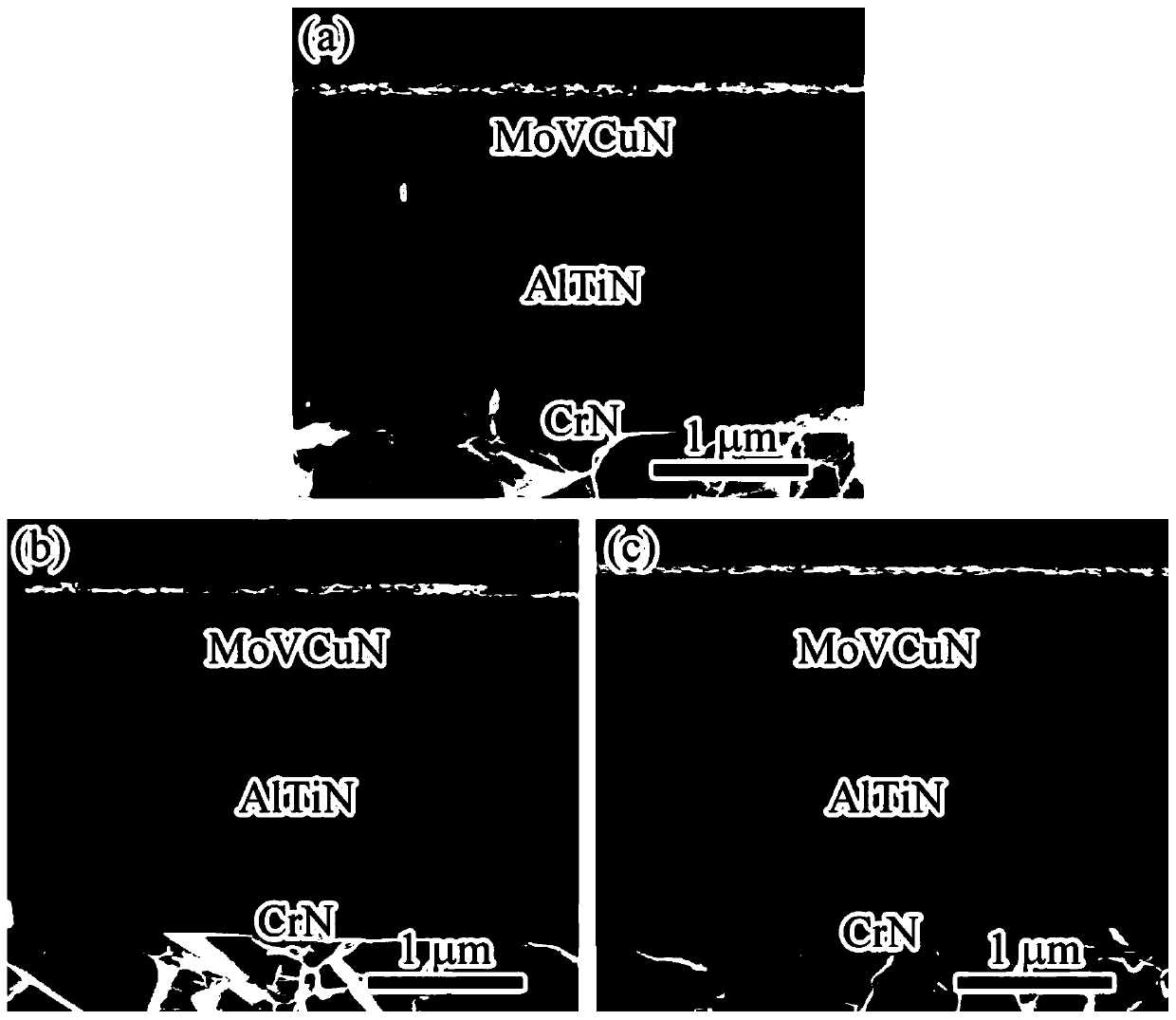

Multilayer multi-element nano composite self-lubricating hard coating and preparation method and application thereof

ActiveCN108866480AImprove performanceHigh hardnessVacuum evaporation coatingSputtering coatingAlloyHardness

The invention belongs to the technical field of preparation of cutter coatings and surface protection coatings, and discloses a multilayer multi-element nano composite self-lubricating hard coating and a preparation method and application thereof. The multilayer multi-element nano composite self-lubricating hard coating comprises a Cr bombardment implant layer, a CrN transition layer, an AlTiN hard core layer and a MoVCuN surface lubricating layer which are deposited on a hard alloy or high-speed steel cutter matrix from bottom to top, wherein the MoVCuN surface lubricating layer is prepared through anode layer ion source-assisted magnetron sputtering deposition; and the MoVCuN surface lubricating layer comprises the following elements by atomic percent: 34 to 44 at.% of Mo, 6 to 10 at.% of V, 0.3 to 0.5 at.% of Cu and 50 to 55 at.% of N. According to the multilayer multi-element nano composite self-lubricating hard coating and the preparation method and application thereof, advantagesof the arc ion plating composite anode layer ion source-assisted magnetron sputtering deposition technology are organically combined, the prepared coating is high in hardness and low in friction coefficient, and a self-lubricating effect of a certain wide-temperature range can be achieved.

Owner:GUANGDONG UNIV OF TECH

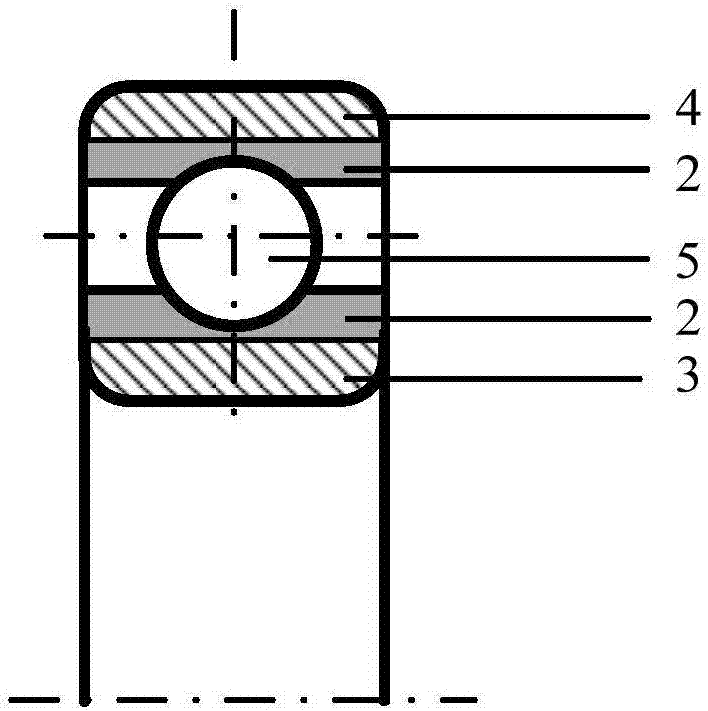

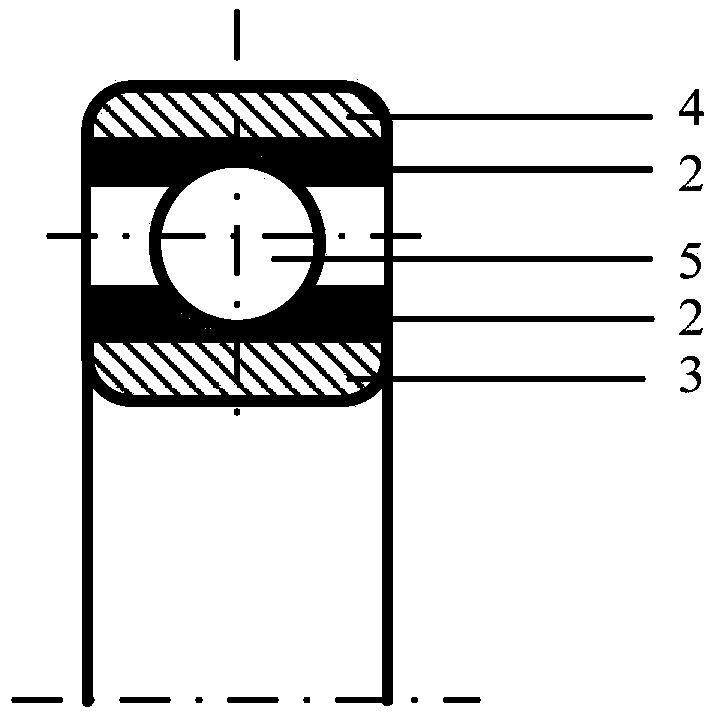

Self-lubricating bearing and preparation method thereof

ActiveCN107460475AAchieve self-lubricating effectExtend your lifeMetallic material coating processesCvd grapheneSilicon nitride

The invention discloses a self-lubricating bearing and a preparation method thereof. According to the self-lubricating bearing, chromium-containing alloy steel is used as a matrix, the working surface of the matrix is a graphene / calcium fluoride / ceramic self-lubricating coating, the coating comprises 30%-50% of nickel-coated aluminum oxide, 20%-40% of nickel-coated silicon nitride, 5%-8% of aluminum-oxide-coated graphene, 5%-8% of aluminum-oxide-coated calcium fluoride, 20%-30% of titanium carbide and 0.5%-2% of nickel, and the sum of weight percentages of all powder is 100%. Graphene and calcium fluoride powder are added in ceramic mixed powder, and the self-lubricating coating is formed on the surface of the matrix material in a fusion covering manner by a laser synchronous powder feeding mode. In the self-lubricating bearing prepared by the method, the binding force between the metal matrix and the self-lubricating coating is large; and meanwhile, the self-lubricating bearing has the characteristics of high surface hardness, good wear resistance and the like. In the working process, a continuous solid lubricating film can be formed on the working surface by means of the self-lubricating coating, and therefore, the self-lubricating function of the bearing is fulfilled.

Owner:SOUTHEAST UNIV

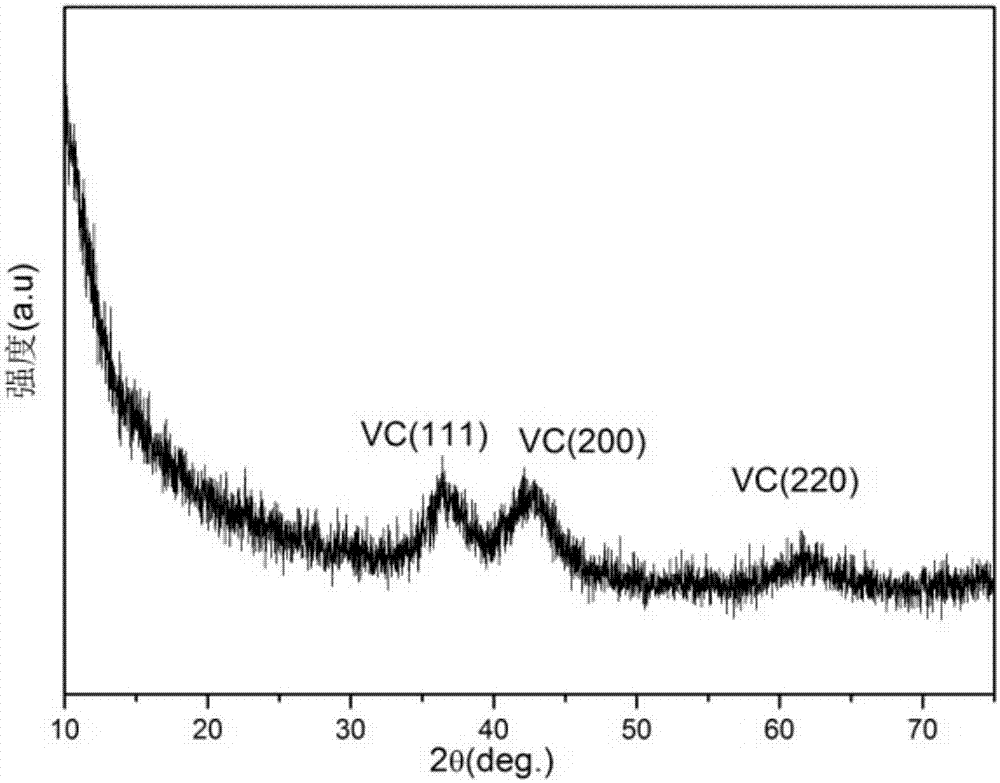

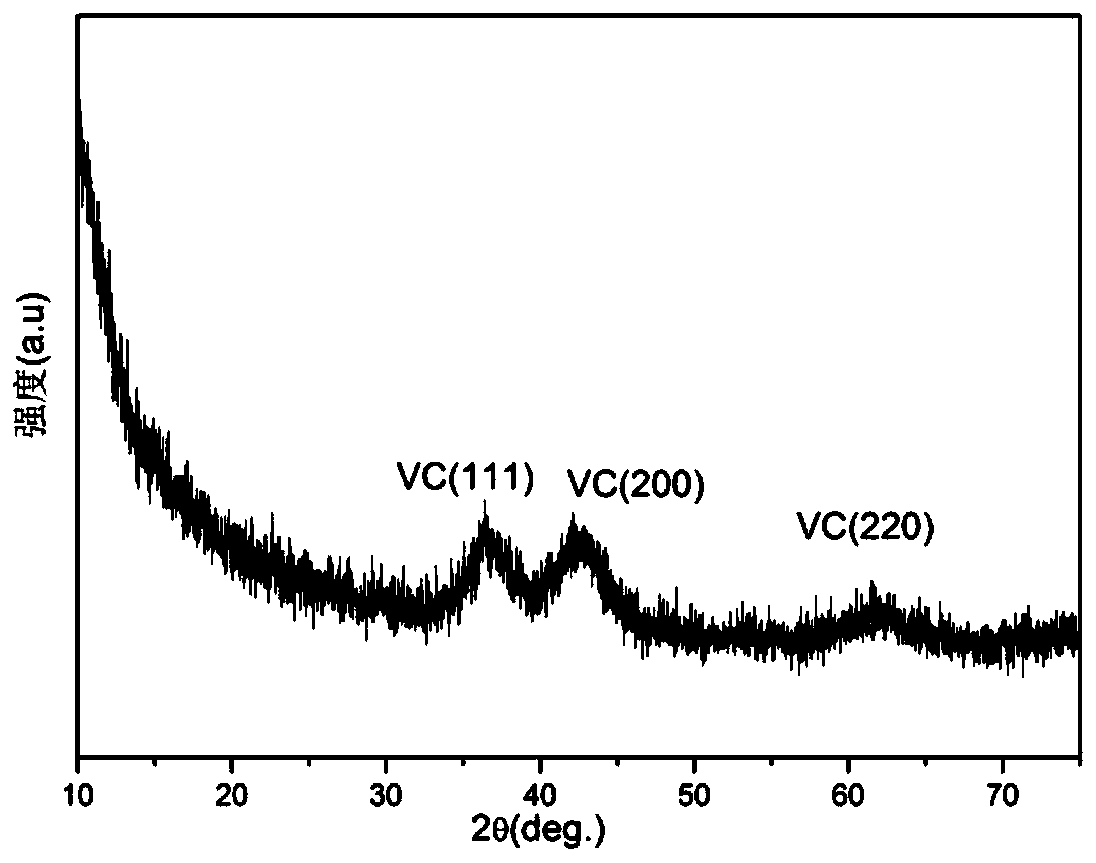

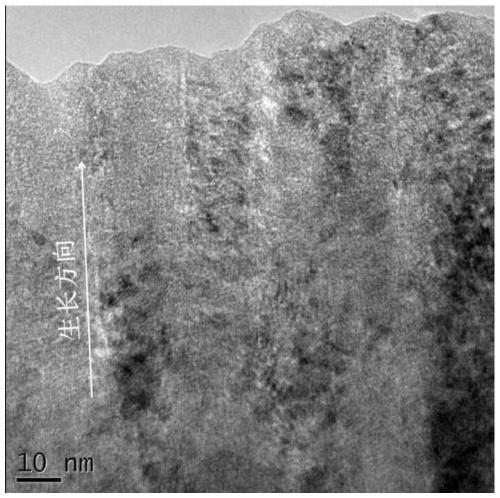

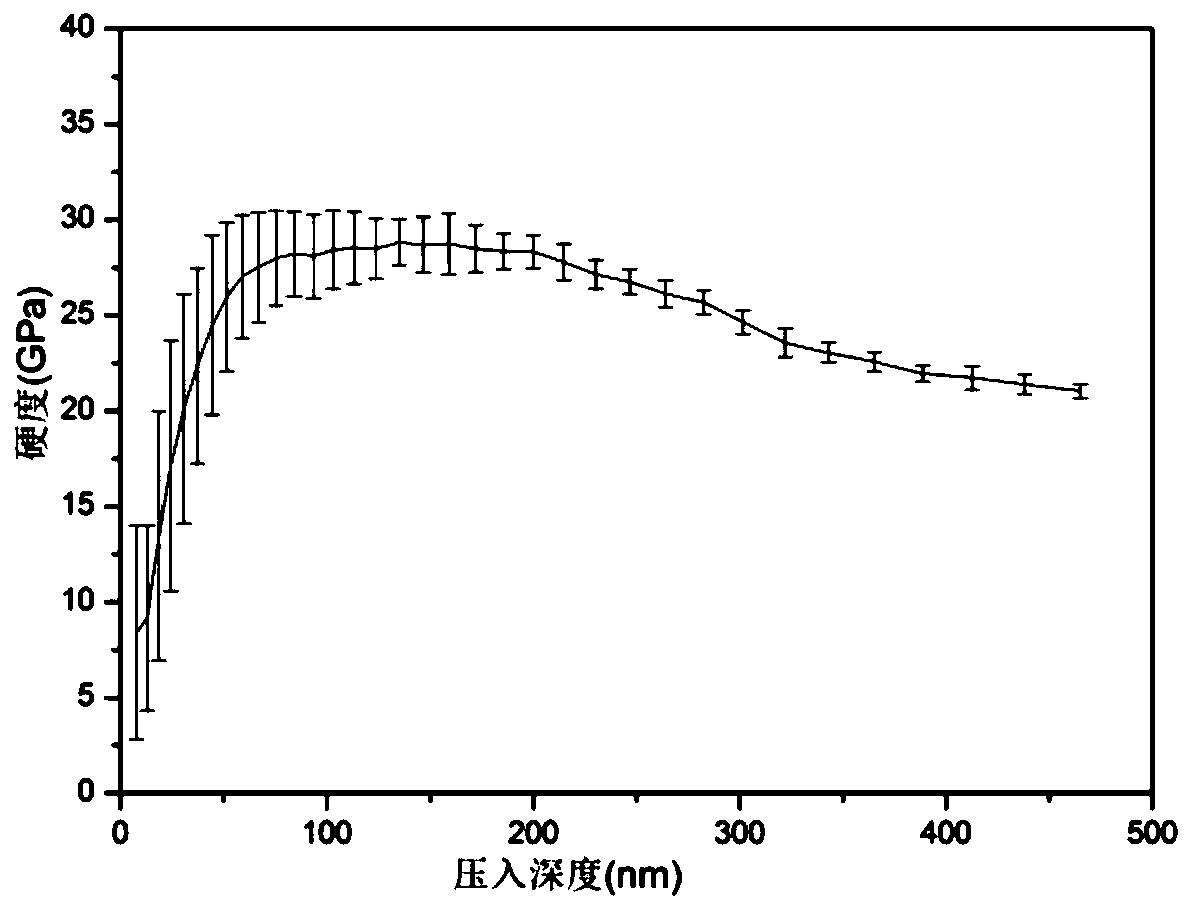

Hard and tough anti-friction protection coating on surface of base body and preparation method of coating

ActiveCN107354442AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingSputteringStructure of the Earth

The invention provides a hard and tough anti-friction protection coating on the surface of a base body. The coating is composed of elements of V, Al and C; Al atoms are dissolved in a VC crystal lattice in a solid state, and a nano-columnar crystal VAlC of a face-centered cubic structure is mainly formed, wherein the content of V is 30-40%, the content of Al is 15-20%, the content of C is 40-55%, and the diameter of the nano crystal VAlC is 10-20 nm. The coating is a hard and tough anti-friction hard coating, adhesion between abrasive dust and the base body is lowered, and the service life of the base body is prolonged. The invention furthermore provides a preparation method of the coating. A direct-current magnetic control sputtering method is adopted, V2AlC is served as the target material, the carbon ingredient is regulated through the gas CH4, the coating structure of the VAlC is adjusted, and the nano-columnar crystal VAlC coating with tiny crystal particles is formed.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

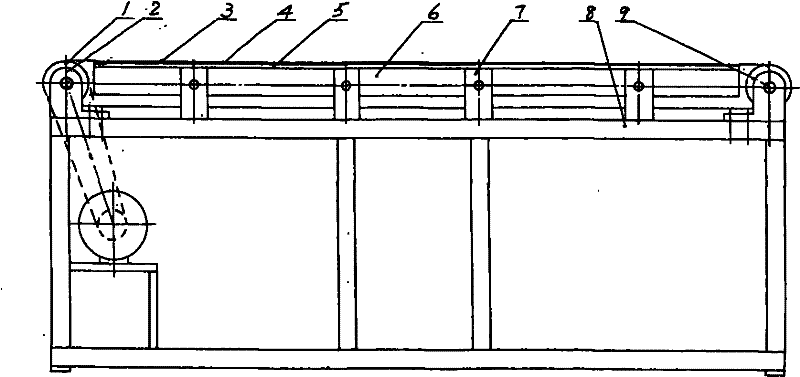

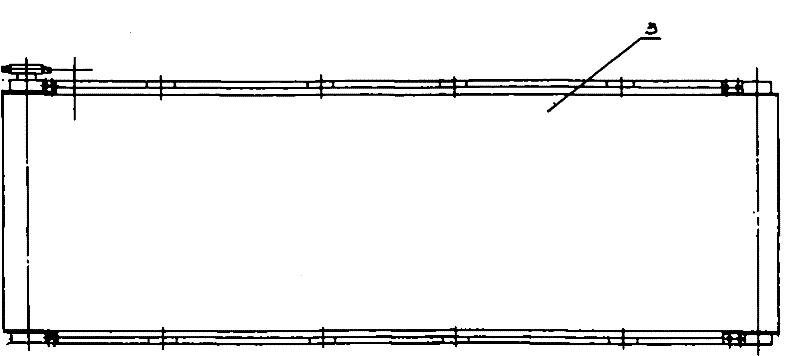

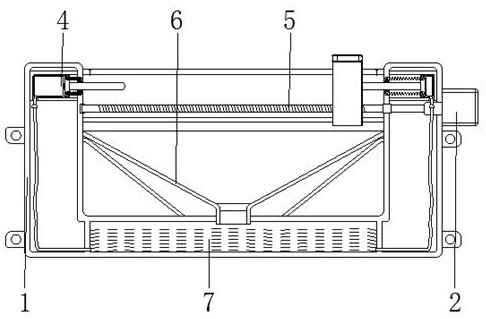

A load-bearing plane conveying device

InactiveCN102259747AAchieve self-lubricating effectWill not increase the loadConveyorsGraphiteEngineering

The invention discloses a load-bearing plane conveying device, which is composed of driving rollers, bearing seats, conveyor belts, graphite gaskets, pallets, brackets, brackets, racks, driven rollers, reduction motors and transmission chains , the driving roller is installed on the left side of the frame, the driven roller is installed on the right side of the frame, the geared motor installed in the middle of the left side of the frame drives the driving roller and the conveyor belt forward through the transmission chain, and the graphite gasket under the conveyor belt , the supporting plate and the bracket are connected together, the graphite gasket is supported by the supporting plate, and the bracket is installed on the frame through the bracket. The present invention designs the load-bearing structure according to the lubricating characteristics, horizontal heat conduction characteristics and transfer characteristics of graphite. The graphite gasket supports the conveyor belt for load-bearing and plays a lubricating role in the relative friction movement. Due to the transfer characteristics of graphite, the graphite will move from The graphite gasket is transferred to the conveyor belt to achieve self-lubrication and reduce the friction coefficient.

Owner:郝钰 +1

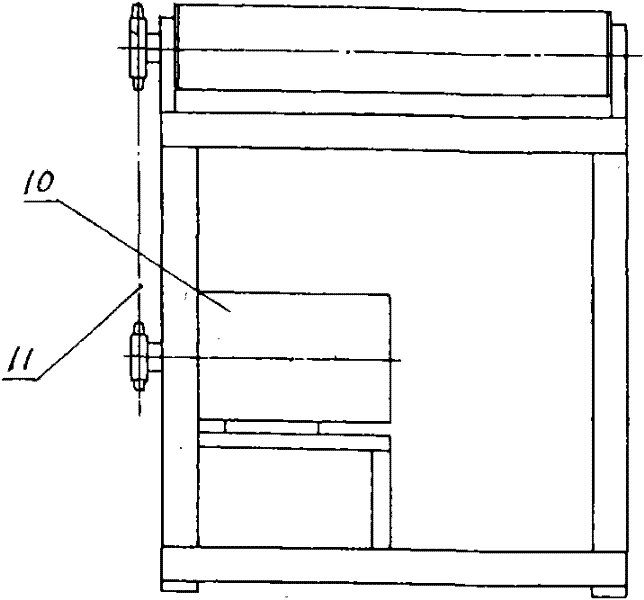

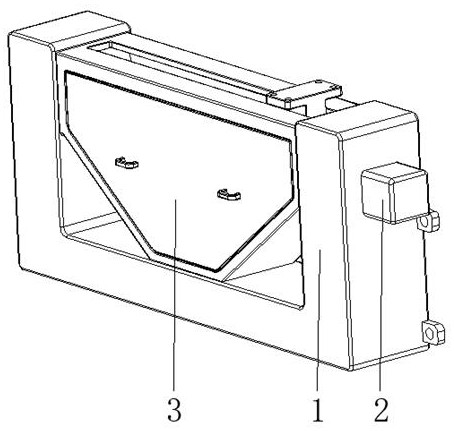

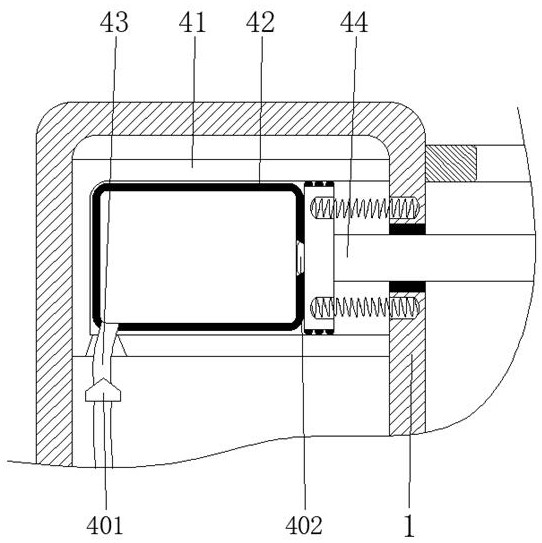

Hollow elevator guide rail

The invention discloses a hollow elevator guide rail, which belongs to the technical field of elevator guide rails and comprises a first combined guide rail body and a second combined guide rail body, wherein a first guide rail seat and a second guide rail seat are fixedly mounted at the bottoms of the first combined guide rail body and the second combined guide rail body respectively. According to the hollow elevator guide rail, an oil guide assembly capable of automatically oiling and an oil smearing brush are arranged in the guide rail; when the guide rail is mounted and used, an elevator runs on the guide rail, heat can be generated through relative friction between the elevator and the guide rail, lubricating oil in the oil guide box can be guided out through the oil outlet via the internally-arranged structure, and the design is reasonable and ingenious. Heat generated by friction between the elevator and the guide rail during operation is utilized, so that the self-lubricating effect is achieved, manual lubrication is not needed, and convenience and rapidness are achieved; and meanwhile, a movable push plate can push out the oil smearing brush at the same time, so that the applied lubricating oil can be effectively smeared, the lubricating oil is more evenly distributed between the elevator and the guide rail, and the use effect of the guide rail is improved.

Owner:张家港鑫菱机械有限公司

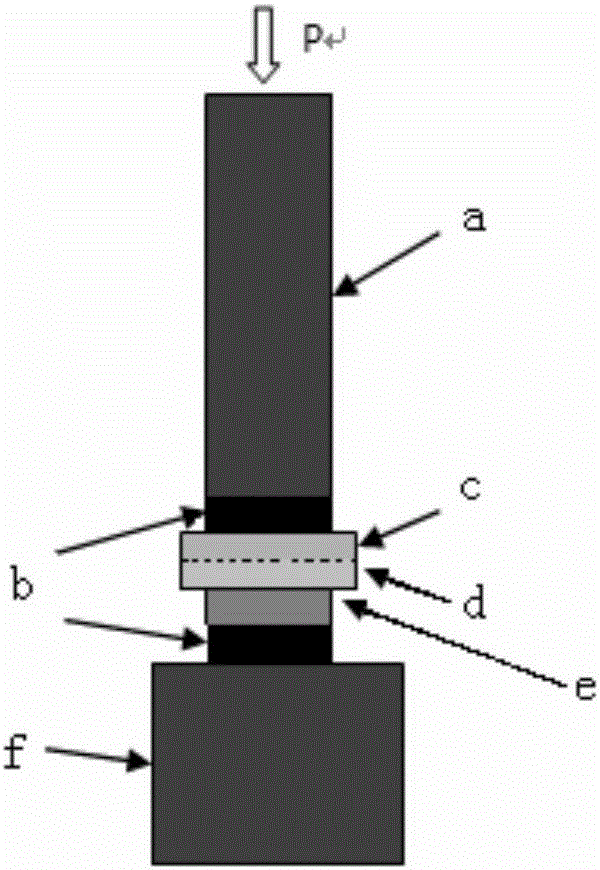

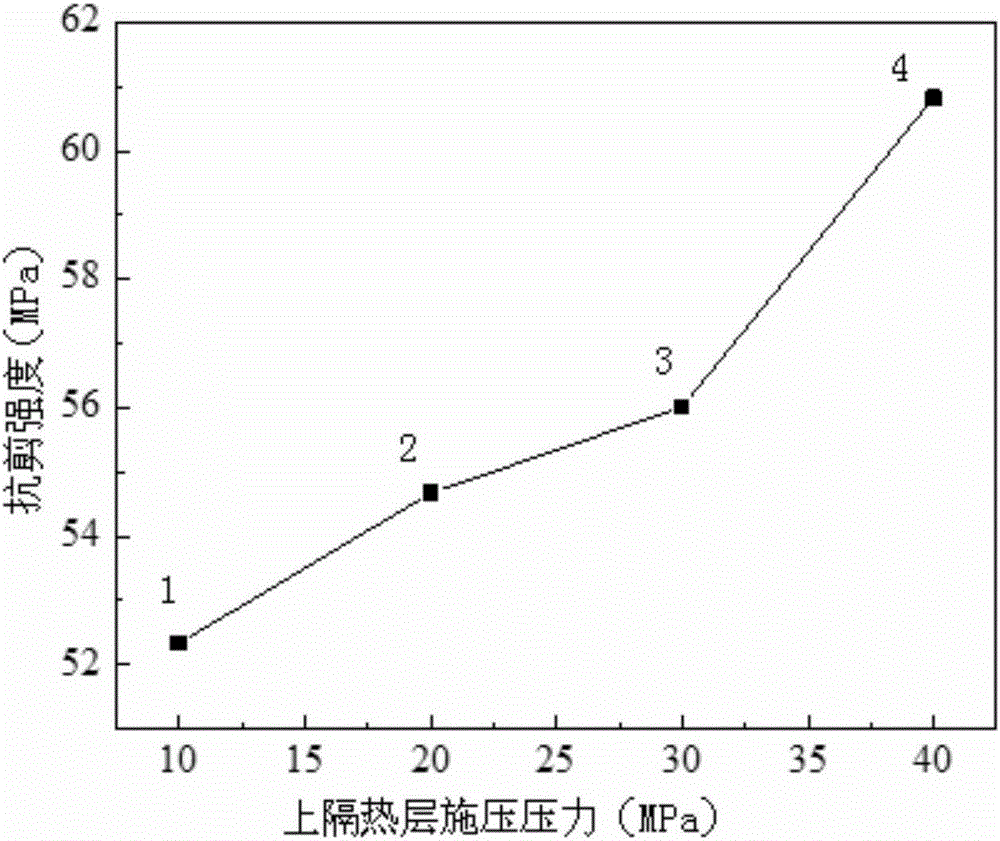

Method for preparing NiAl system intermetallic compound composite self-lubricating coating through self-propagating method

ActiveCN105290406AImprove the lubrication effectReduce coefficient of frictionCombustionIntermetallic

The invention belongs to the technical field of overlaying, and particularly relates to a method for preparing an NiAl system intermetallic compound composite self-lubricating coating through a self-propagating method. The method aims to solve the problems that a self-lubricating coating prepared through an existing method is short in wear resisting time, complex in process, high in cost and limited in use temperature. The method comprises the steps that firstly, an Ni-Al pressing blank is pressed according to the molar ratio of 1:1; secondly, a 3Ni-Al-MoS2 pressing blank is pressed according to the molar ratio of 3:1; and thirdly, the 3Ni-Al-MoS2 pressing blank, the Ni-Al pressing blank and a metal base body are stacked from top to bottom, then the Ni-Al pressing blank is ignited, pressurization is carried out while igniting is carried out, pressure relief is carried out after combustion is finished, and the NiAl system intermetallic compound composite self-lubricating coating is obtained. The coating prepared through the method has the remarkable lubricating effect; the process for preparing the coating is quick and high in efficiency; and energy is saved, and environment friendliness is achieved.

Owner:HARBIN INST OF TECH

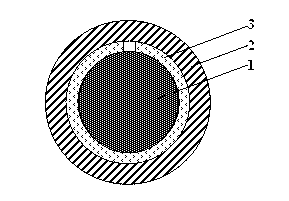

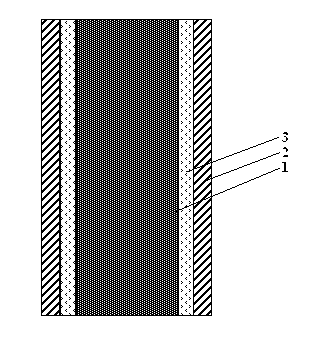

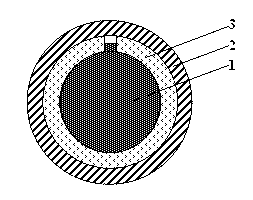

Low-volatile organic gas polyurethane enameled wire and manufacturing process thereof

ActiveCN112133494AReduce surface friction coefficientImprove slipperyPlastic/resin/waxes insulatorsClimate change adaptationChemistryControl system

The invention discloses a manufacturing process of a low-volatile organic gas polyurethane enameled wire. The manufacturing process comprises the following steps: (1), performing wire drawing; (2), performing annealing; (3), performing painting; (4), performing baking; (5), performing cooling; and (6), performing take-up. The invention also discloses a low-volatile organic gas polyurethane enameled wire which is composed of a metal conductor and a polyurethane insulating layer with self-lubricating performance. A fluorine-containing group is introduced into a polyurethane molecular chain of the insulating paint to form a polyurethane insulating layer with self-lubricating performance, a traditional lubricating oil layer is replaced, and a lubricating layer does not need to be specially coated; a problem that the whole electronic control system is out of control or paralyzed due to the fact that volatile gas corrodes the contact surface of an electronic component in a closed environmentcaused by volatilization of lubricating oil on the surface of an enameled wire and residual volatile gas of a polyurethane insulating layer is well solved. And a problem that the requirement of a sealed electronic component on the volatile organic gas content of the enameled wire cannot be met is also solved.

Owner:ZHUHAI RONSEN SUPER MICRO WIRE CO LTD

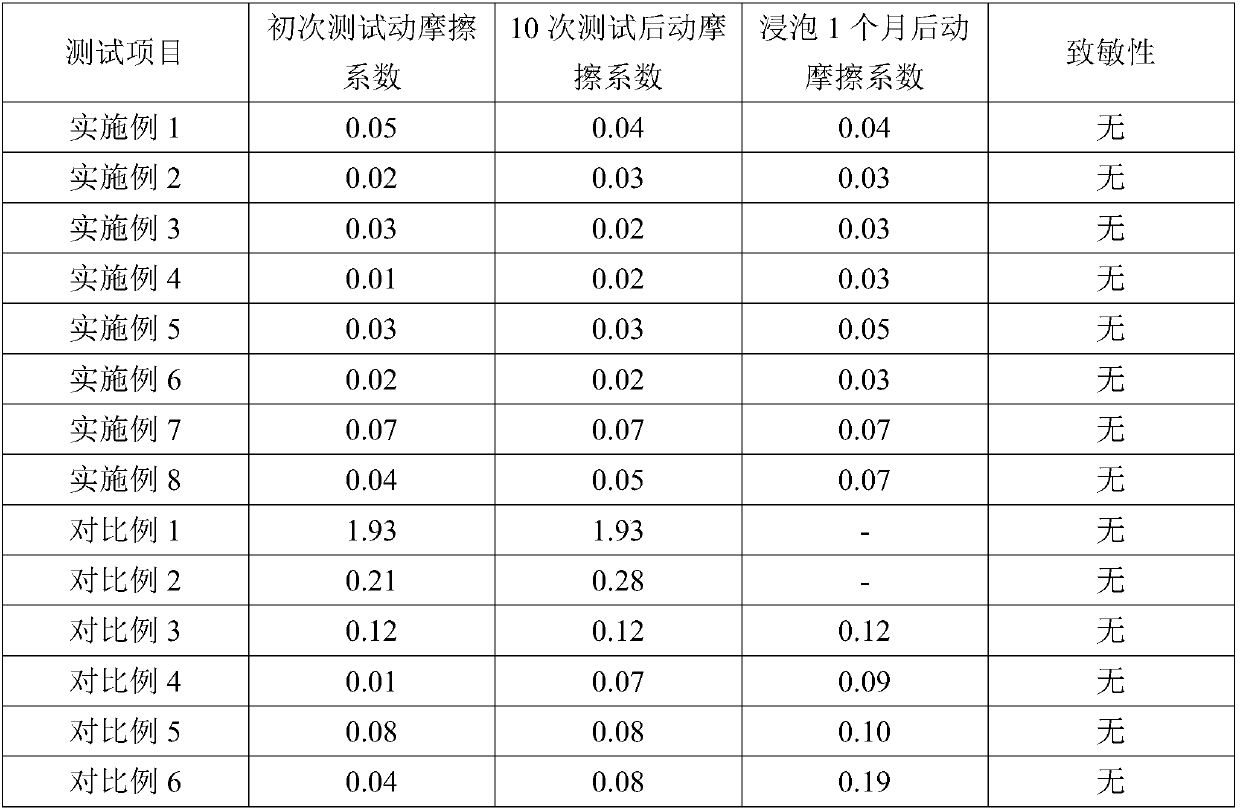

Hydrophilic lubricant auxiliary agent masterbatch and preparation method thereof, and hydrophilic self-lubricating polymer material including the same

The invention provides hydrophilic lubricant auxiliary agent masterbatch and a preparation method thereof, and a hydrophilic self-lubricating polymer material including the same. The masterbatch includes, by weight percentage, 20-93% of an amphiphilic oligomer, 2-30% of a hydrophilic polymer material and 5-50% of a hydrophobic polymer material; the amphiphilic oligomer includes a hydrophilic chainsection and an oleophilic chain section, the number average molecular weight of the hydrophilic chain section is 300-3,000, and the number average molecular weight of the oleophilic chain section is300-3,000; and the hydrophilic self-lubricating polymer material includes 60-99 parts by weight of a polymer matrix material and 1-40 parts by weight of hydrophilic lubricant auxiliary agent masterbatch. The provided masterbatch can effectively enhance the hydrophilic lubrication performance of the polymer material, and is lasting in lubrication effect; and the polymer material can be directly molded to prepare medical instruments without coating self-lubricating coatings or lubricants.

Owner:谭斌

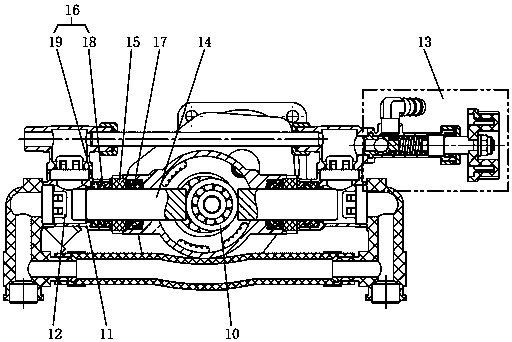

Self-lubricating plunger pump

PendingCN107701420APlay a lubricating rolePlay a self-lubricating effectPositive displacement pump componentsPiston pumpsEngineeringMechanical engineering

The invention discloses a self-lubricating plunger pump. The plunger pump comprises a pump body and a power mechanism connected with the pump body; two symmetrical plunger assemblies are arranged in the pump body; the two plunger assemblies are arranged in two pressure chambers respectively, one ends of the two pressure chambers communicate with the water inlet and outlet valve, and the other endsof the two pressure chambers penetrate into the position of a movable bearing, and the water inlet and outlet valve is connected with a pressure regulating valve; and the plunger assemblies compriseplunger inserted into the pressure chambers, wherein wool felts are arranged on the plungers in a sleeving mode, water seals and oil seals are arranged on the two sides of the wool felts, the outer rings of the water seals abut against and are fastened on the inner walls of the pressure chambers, the oil seals abut against the wool felts and are fastened on the inner walls of the pump body, and the wool felts are filled with machine oil. The self-lubricating plunger pump has the advantages that butter-free and self-lubricating are reliazed, structure is compact, installation is convenient, size is small, weight is light and the like.

Owner:TAIZHOU SUNNY AGRI MACHINERY

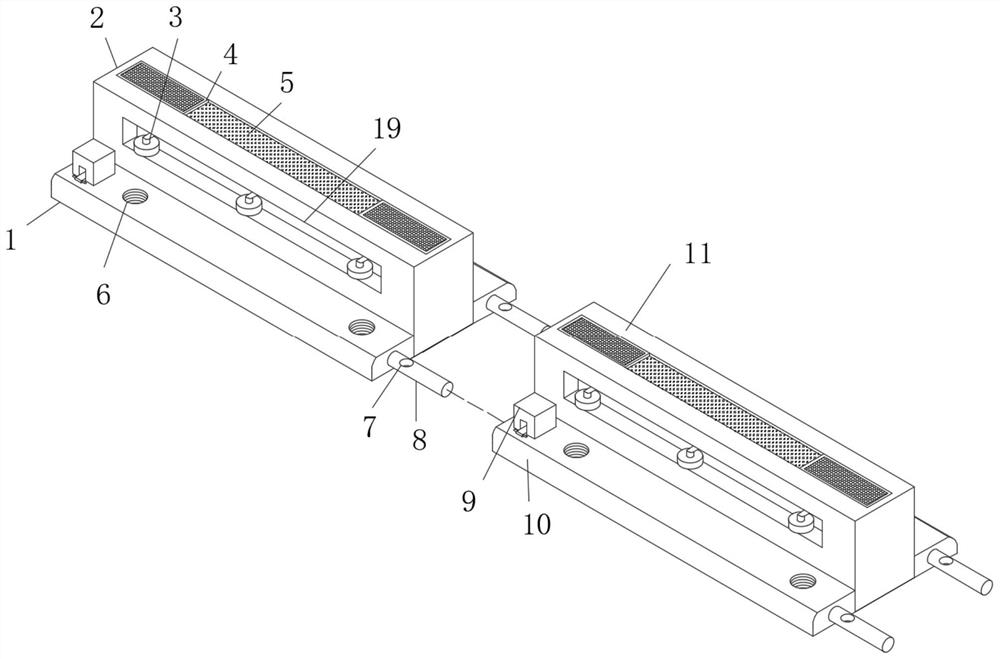

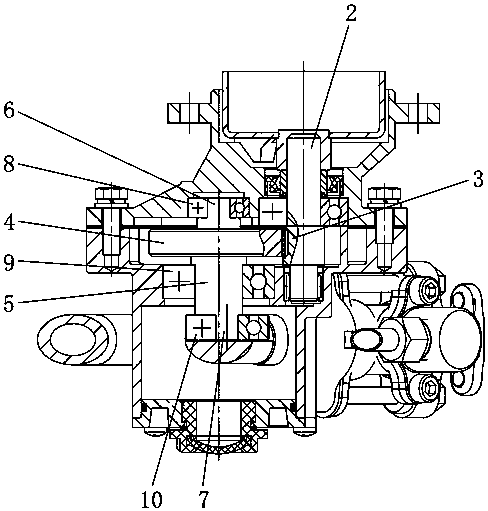

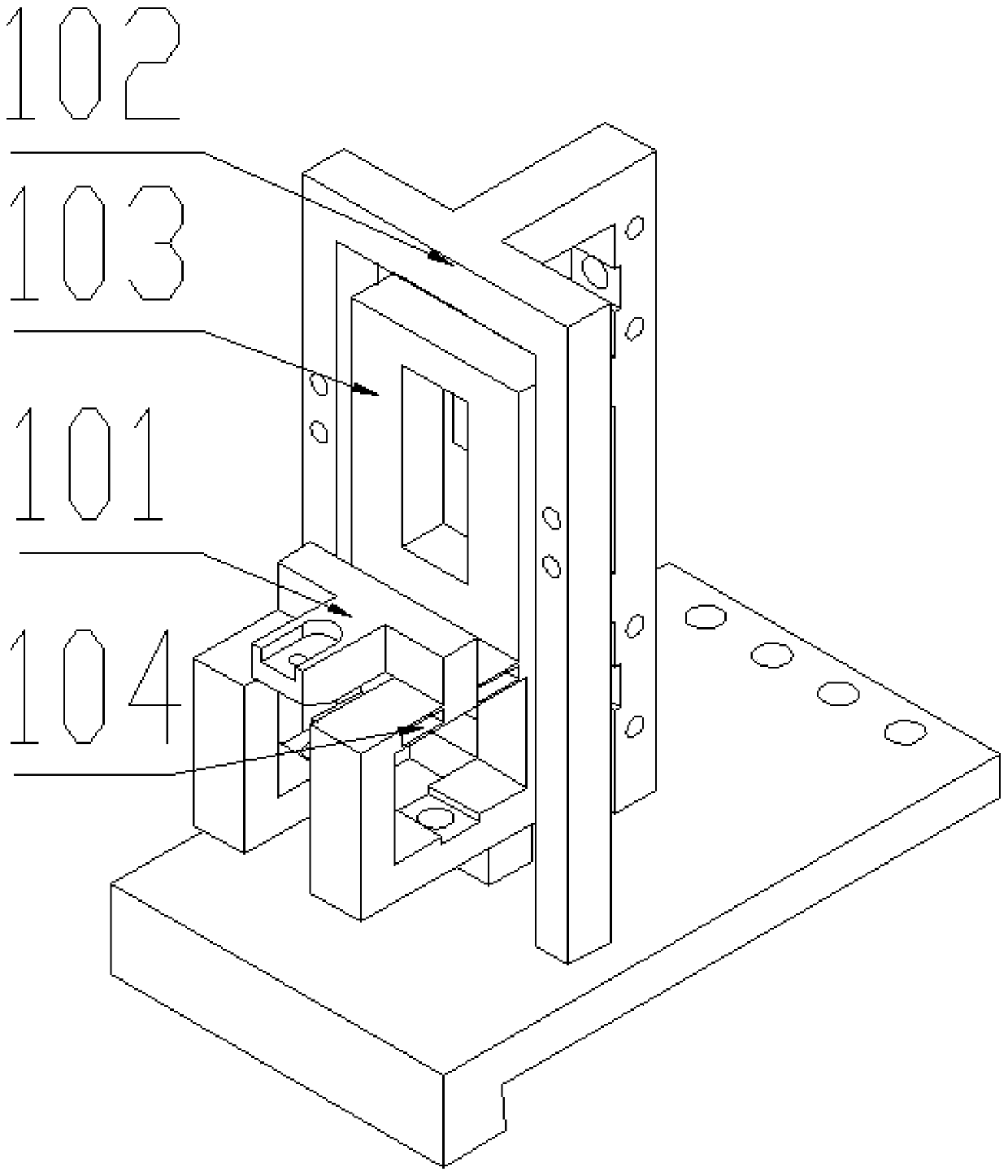

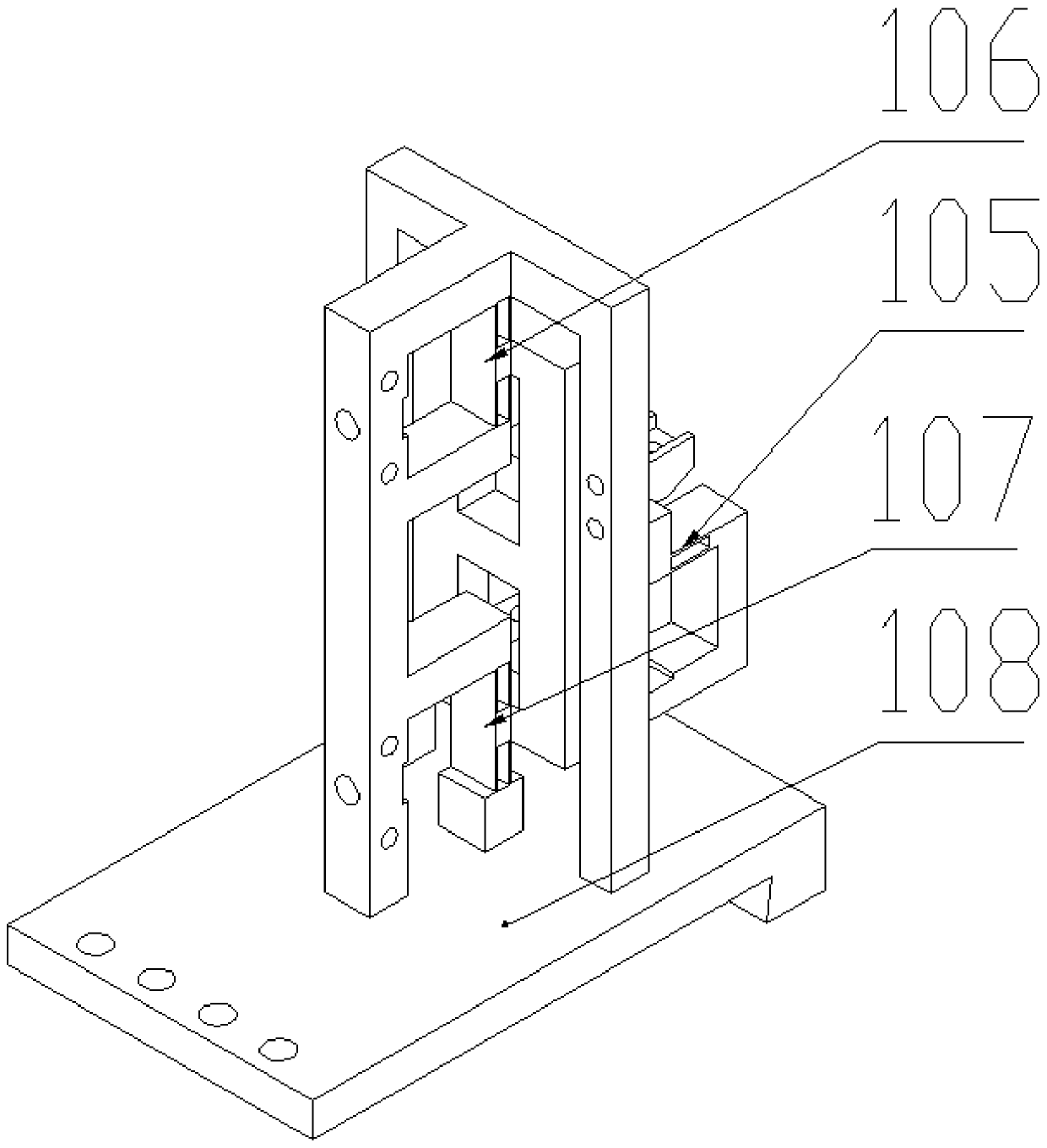

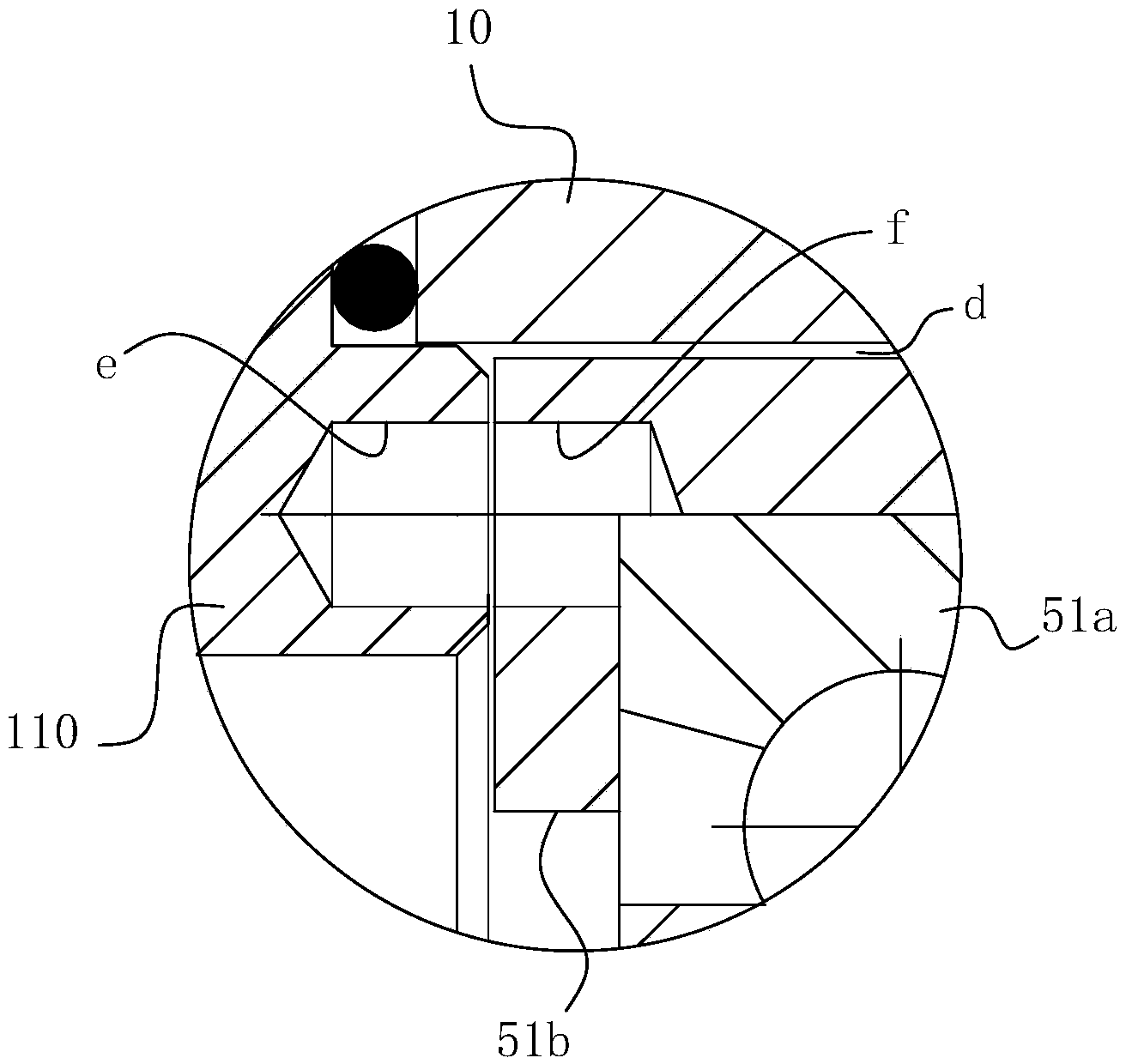

Three-dimensional elliptical vibration flexible device based on metal porous material

PendingCN111408749AGuaranteed motion accuracyRealize the self-lubricating effect of the mechanismTool holdersMachine toolCapacitive displacement sensor

The invention relates to a three-dimensional elliptical vibration flexible device based on a metal porous material, and belongs to the technical field of optical part machining. The device is characterized in that a cutter is fixed in a cutter groove in the middle of a T-shaped cutter holder of a flexible base body through a bolt; the heads of piezoelectric stacks in the vertical direction are incontact with straight plate type flexible hinges, pre-tightening blocks are tightened through bolts to pre-tightening the lower ends of the piezoelectric stacks, and capacitive displacement sensors are clamped on sensor clamps; the heads of piezoelectric stacks in the horizontal direction are in contact with straight plate type flexible hinges, and capacitive displacement sensors are clamped on sensor clamps; and the lower portion of a base is connected with dovetail strips through bolts. The device has the advantages that the flexible base body can effectively reduce vibration conducted to amachine tool guide rail from a tool nose, the motion precision of the device is guaranteed, the self-lubricating effect of a mechanism is achieved, the service life is prolonged, and cutting machiningon various face types can be achieved; and meanwhile, the four piezoelectric stacks are provided with the capacitive displacement sensors for monitoring actual displacement in real time and feeding back the actual displacement to a controller for compensation, so that the machining precision is high.

Owner:JILIN UNIV

A kind of multi-layer multi-component nano-composite self-lubricating hard coating and its preparation method and application

ActiveCN108866480BImprove performanceHigh hardnessVacuum evaporation coatingSputtering coatingCemented carbideMaterials science

The invention belongs to the technical field of preparation of cutter coatings and surface protection coatings, and discloses a multilayer multi-element nano composite self-lubricating hard coating and a preparation method and application thereof. The multilayer multi-element nano composite self-lubricating hard coating comprises a Cr bombardment implant layer, a CrN transition layer, an AlTiN hard core layer and a MoVCuN surface lubricating layer which are deposited on a hard alloy or high-speed steel cutter matrix from bottom to top, wherein the MoVCuN surface lubricating layer is prepared through anode layer ion source-assisted magnetron sputtering deposition; and the MoVCuN surface lubricating layer comprises the following elements by atomic percent: 34 to 44 at.% of Mo, 6 to 10 at.% of V, 0.3 to 0.5 at.% of Cu and 50 to 55 at.% of N. According to the multilayer multi-element nano composite self-lubricating hard coating and the preparation method and application thereof, advantagesof the arc ion plating composite anode layer ion source-assisted magnetron sputtering deposition technology are organically combined, the prepared coating is high in hardness and low in friction coefficient, and a self-lubricating effect of a certain wide-temperature range can be achieved.

Owner:GUANGDONG UNIV OF TECH

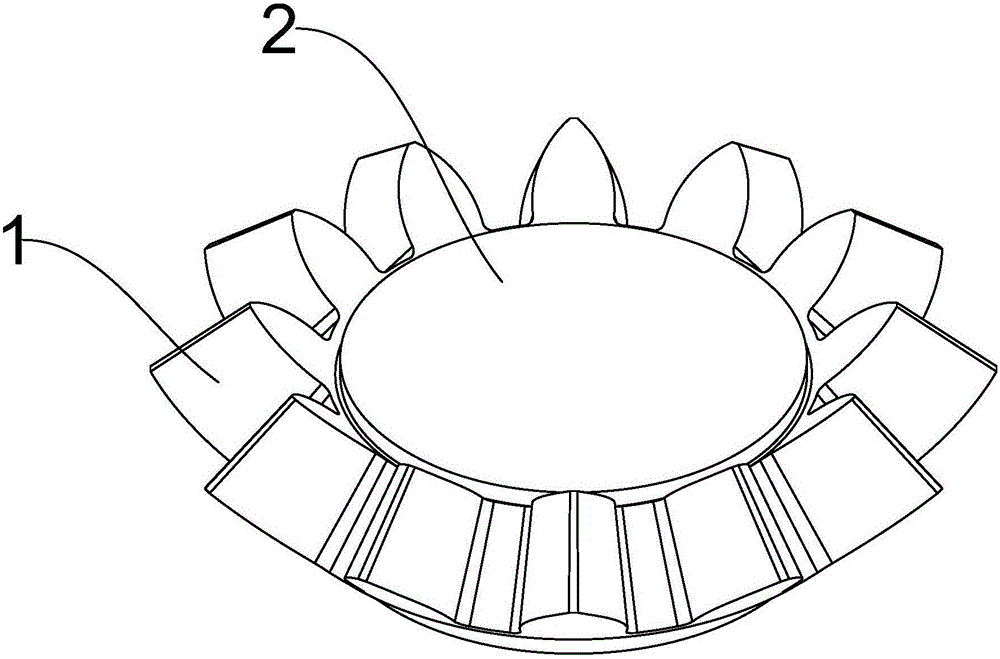

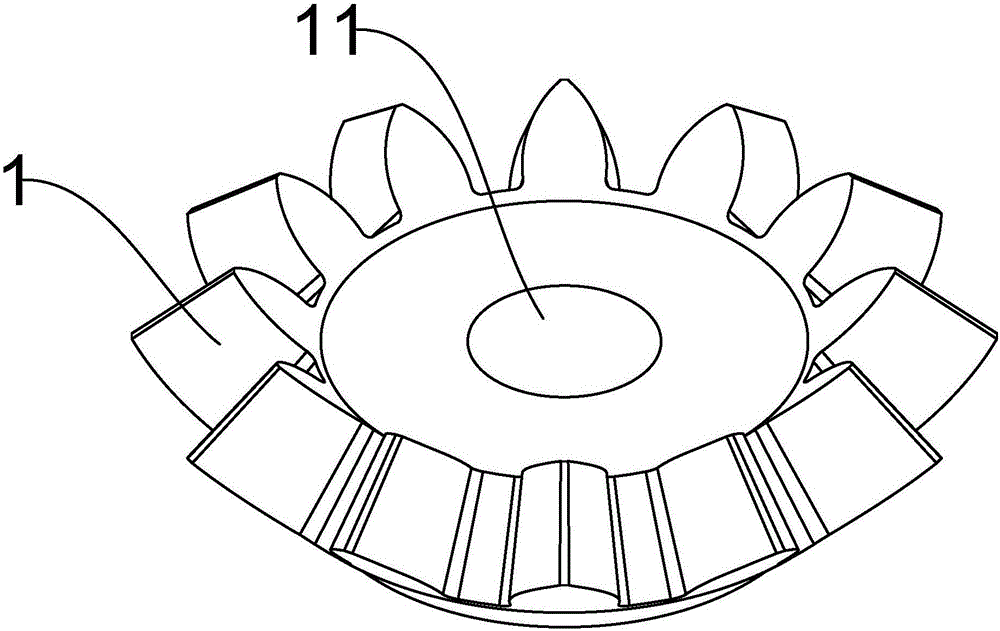

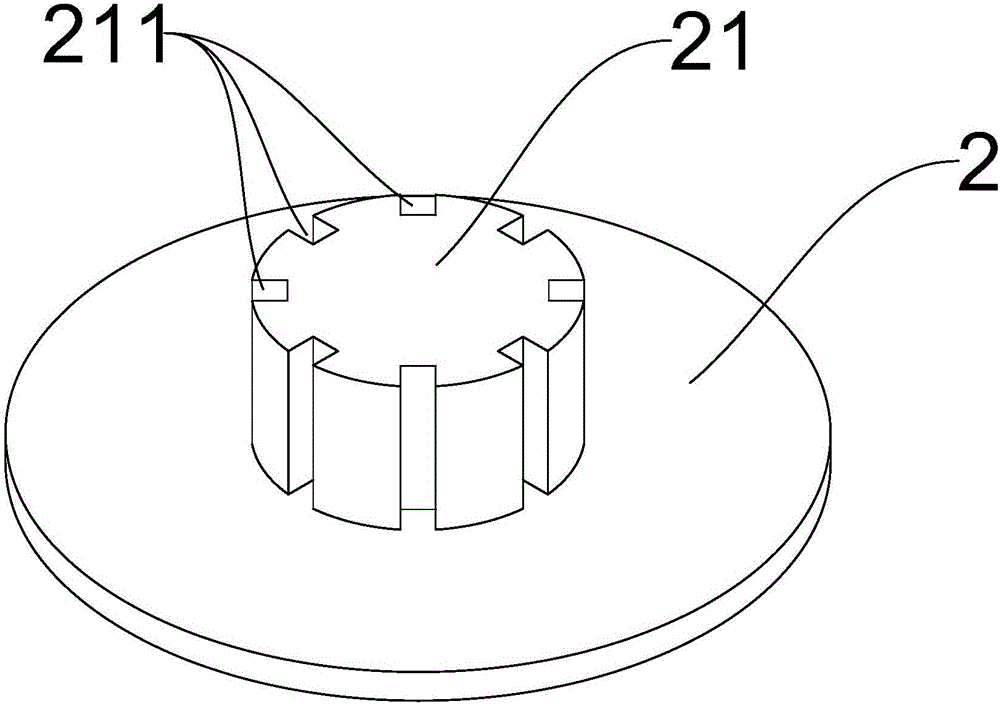

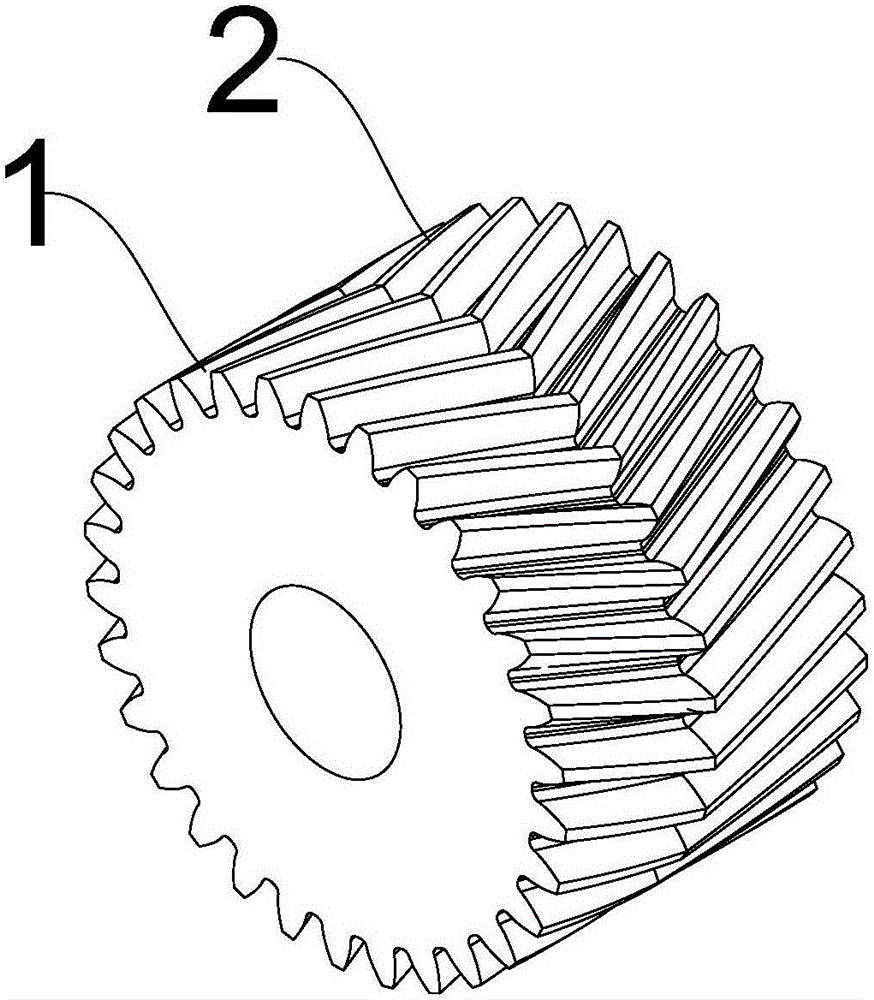

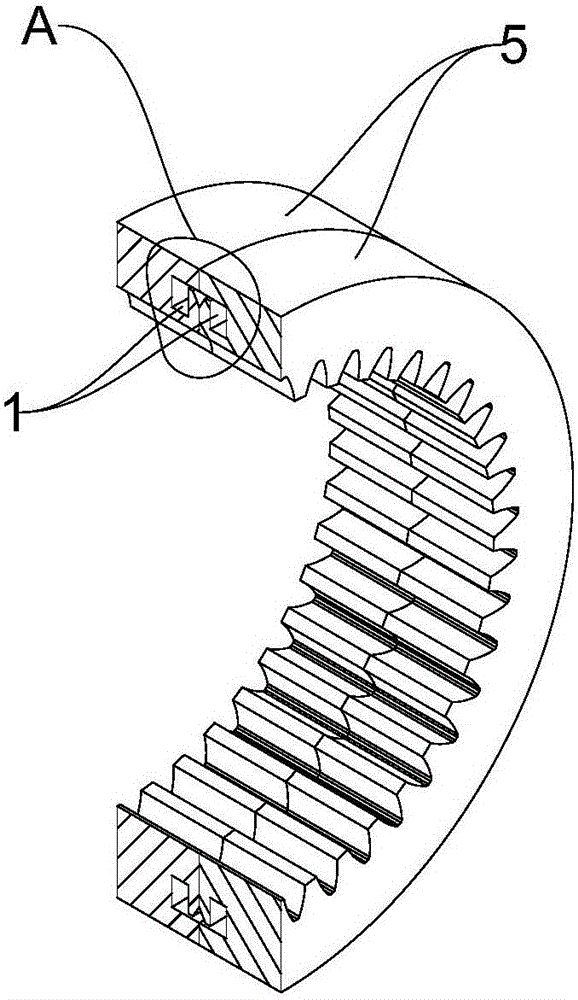

Self-lubricating bevel gear provided with oil storage cavity

PendingCN105937607AAchieve self-lubricating effectPortable liftingGear lubrication/coolingGear wheelOil distribution

The invention discloses a self-lubricating bevel gear provided with an oil storage cavity. The self-lubricating bevel gear provided with the oil storage cavity comprises a bevel gear body. The oil storage cavity is formed in the center of the top of the bevel gear body and is cylindrical. An inner thread is arranged at the end of the oil storage cavity. Lubricating oil is contained in the oil storage cavity. The self-lubricating bevel gear provided with the oil storage cavity further comprises an oil distribution cover plate which is of a round structure. A plunger is arranged at the bottom of the oil distribution cover plate, and a plurality of oil outlet grooves are evenly formed in the surface of the plunger. The self-lubricating bevel gear provided with the oil storage cavity has the advantages that the self-lubricating bevel gear provided with the oil storage cavity is provided with the plunger provided with the oil outlet groove structures, and the oil distribution cover plate; and when the bevel gear rotates, the lubricating oil flows out along the oil outlet grooves under the action of centrifugal force and then slowly and evenly flows out of clearances between the oil distribution cover plate and the end face of the bevel gear, afterwards, the lubricating oil is cast to the bevel gear, and therefore the self-lubricating function is achieved.

Owner:TAIZHOU JINXIN MACHINERY

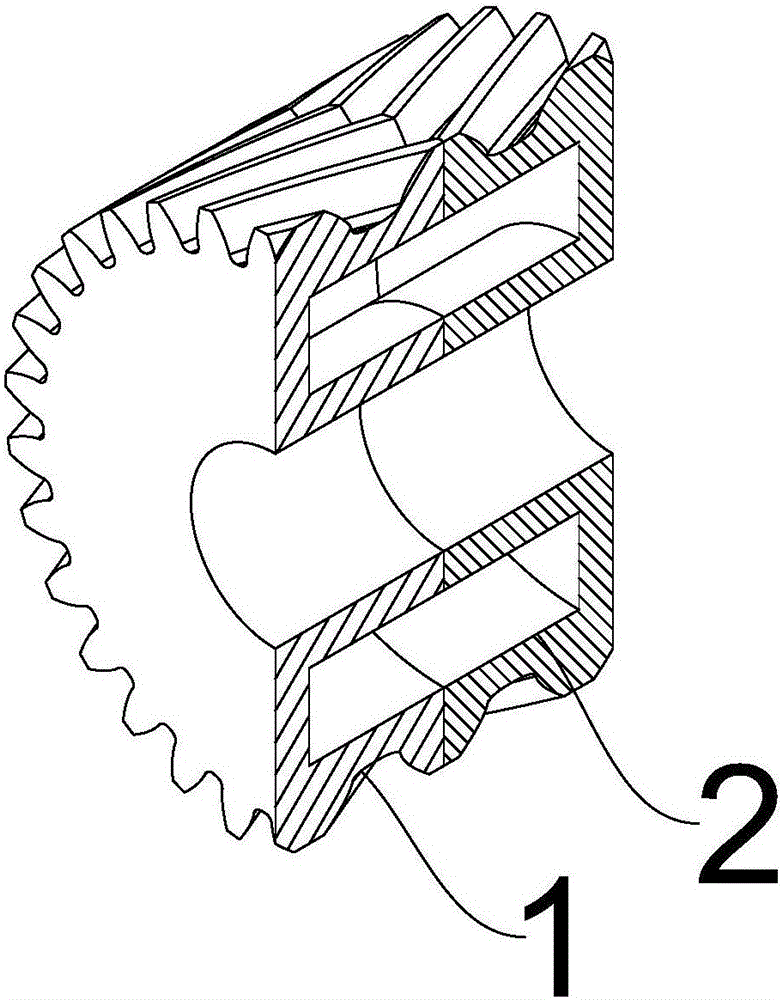

Herringbone gear with annular oil storage cavity

InactiveCN105937605AReduce processing costsAchieve self-lubricating effectPortable liftingGear lubrication/coolingHerringbone gearGear tooth

The invention discloses a herringbone gear with an annular oil storage cavity. The herringbone gear comprises a left part and a right part; the left part and the right part are mutually mirror images; annular grooves are formed in the bonding surfaces of the left part and the right part; and the two annular grooves are combined to the annular oil storage cavity. The herringbone gear with the annular oil storage cavity has the following advantages: the herringbone gear adopts a split structure consisting of the left part and the right part, can largely reduce the machining cost, is provided with the oil storage cavity inside, and can slowly supply lubricating oil into gear teeth by using a gap between the left part and the right part to achieve a self-lubricating effect.

Owner:TAIZHOU JINXIN MACHINERY

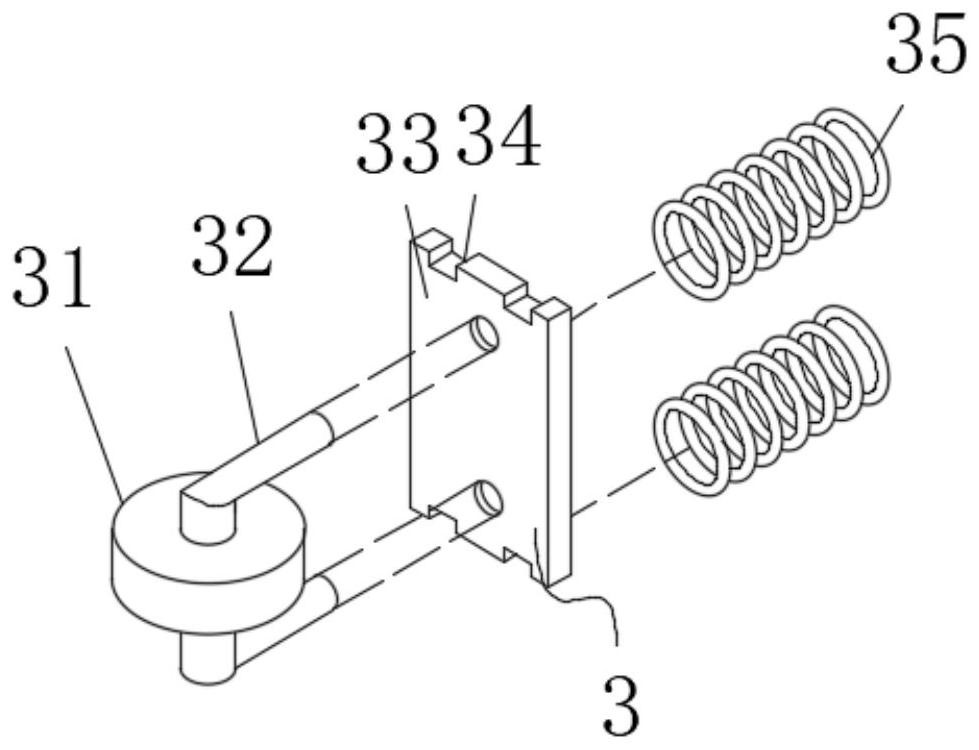

Sewing-machine self-lubricating oil-storage connecting rod mechanism

PendingCN106120191AGuaranteed to workExtended working hoursLubrication/cooling devicesSewing-machine control devicesCushionWheel and axle

The invention discloses a sewing-machine self-lubricating oil-storage connecting rod mechanism. The sewing-machine self-lubricating oil-storage connecting rod mechanism comprises a large connecting-rod eccentric wheel. The surface of an outer ring of the large connecting-rod eccentric wheel is matched with a large connecting rod, one side of the large connecting-rod eccentric wheel is matched with a large-connecting-rod-eccentric-wheel fixing frame, the other side of the large connecting-rod eccentric wheel is matched with a cloth feeding cam pressing piece, a set of felt cushion blocks are arranged in the large-connecting-rod-eccentric-wheel fixing frame, a large-connecting-rod-eccentric-wheel shaft hole is formed in the large connecting-rod eccentric wheel, and an upper shaft is arranged in the large-connecting-rod-eccentric-wheel shaft hole, and sequentially penetrates through the large-connecting-rod-eccentric-wheel fixing frame, the large-connecting-rod-eccentric-wheel shaft hole and the cloth feeding cam pressing piece. The sewing-machine self-lubricating oil-storage connecting rod mechanism has the advantages that when the large connecting-rod eccentric wheel moves, lubricating oil of the felt cushion blocks is automatically oozed out to lubricate the large connecting-rod eccentric wheel, the self-lubricating effect is achieved, it is avoided that abrasion of the large connecting-rod eccentric wheel appears to cause damage, the service life of a sewing machine is prolonged, the felt cushion blocks only need to be filled with lubricating oil during maintaining, the felt cushion blocks can be reused, the using effect is good, and popularization is facilitated.

Owner:浙江恒强针车集团有限公司

A low volatile organic gas polyurethane enameled wire and its manufacturing process

ActiveCN112133494BReduce surface friction coefficientMeet the requirements of volatile organic gas contentPlastic/resin/waxes insulatorsClimate change adaptationPolymer scienceElectrical conductor

The invention discloses a manufacturing process of low volatile organic gas polyurethane enameled wire, which comprises the following steps: (1) wire drawing; (2) annealing; (3) painting; (4) baking; (5) cooling; (6) Reel up. The invention also discloses a low volatile organic gas polyurethane enameled wire, which is composed of a metal conductor and a polyurethane insulating layer with self-lubricating properties. The invention introduces a fluorine-containing group into the polyurethane molecular chain of the insulating varnish to form a polyurethane insulating layer with self-lubricating properties, which replaces the traditional lubricating oil layer and does not need to be specially coated with a lubricating layer. The residual volatile gas of the polyurethane insulating layer causes the volatile gas to corrode the contact surface of electronic components in a closed environment, resulting in the loss of control or paralysis of the entire electronic control system. And the problem of being unable to meet the requirements of the sealed electronic components for the volatile organic gas content of the enameled wire.

Owner:ZHUHAI RONSEN SUPER MICRO WIRE CO LTD

High-strength self-lubricating polyurethane piston sealing body and preparation method thereof

PendingCN113980457ASimple production processLow costPositive displacement pump componentsBuilding material handlingPistonPolymer chemistry

The invention relates to the field of polymer materials, in particular to a high-strength self-lubricating polyurethane piston sealing body and a preparation method thereof. Specifically, the invention relates to a composition which can be used for preparing a piston sealing body, the piston sealing body prepared from the composition, and a method for preparing the piston sealing body. The piston sealing body can be used as a concrete piston sealing body for concrete pumping equipment.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Narrow-granularity thermally-stable tungsten carbide powder and preparation method thereof

InactiveCN114772599ARealize self-lubricationAchieving Corrosion ResistanceTungsten/molybdenum carbideTungstateThiadiazoles

The invention discloses narrow-granularity thermally-stable tungsten carbide powder and a preparation method thereof, and relates to the technical field of metal powder. The preparation method comprises the following steps: firstly, alternately etching graphite by using hydrogen and oxygen plasmas, and then stripping by using an adhesive tape and ultrasonic airflow to obtain a narrow-granularity graphene nanosheet; the preparation method comprises the following steps: solidifying an ammonium tungstate solution at an ultralow temperature to wrap all graphene nanosheets, and then growing tungsten carbide nanosheets on the surfaces of the graphene nanosheets through an alternating microwave magnetic field to obtain graphene-tungsten carbide-graphene sandwich type nanosheet powder, so that the surface roughness of the tungsten carbide powder is reduced, and the self-lubricating effect of the tungsten carbide powder is realized; the preparation method comprises the following steps: firstly preparing a graphene nanosheet, then modifying the graphene nanosheet by using dimethyl succinic anhydride, 2-chlorobenzoin aldehyde, 2, 5-dimercapto-1, 3, 4-thiadiazole and hydrazine hydrate to form a thicker and compact protective film and an isolating layer, and effectively blocking corrosion elements. The prepared tungsten carbide powder has the effects of narrow particle size distribution, self-lubrication and corrosion resistance.

Owner:滁州用朴新材料科技有限公司

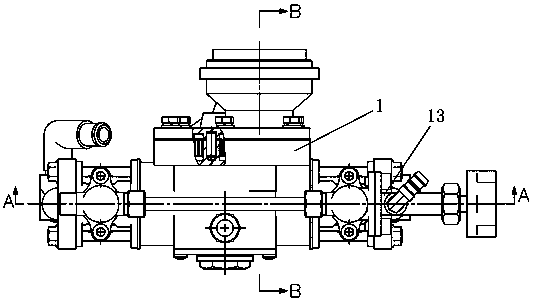

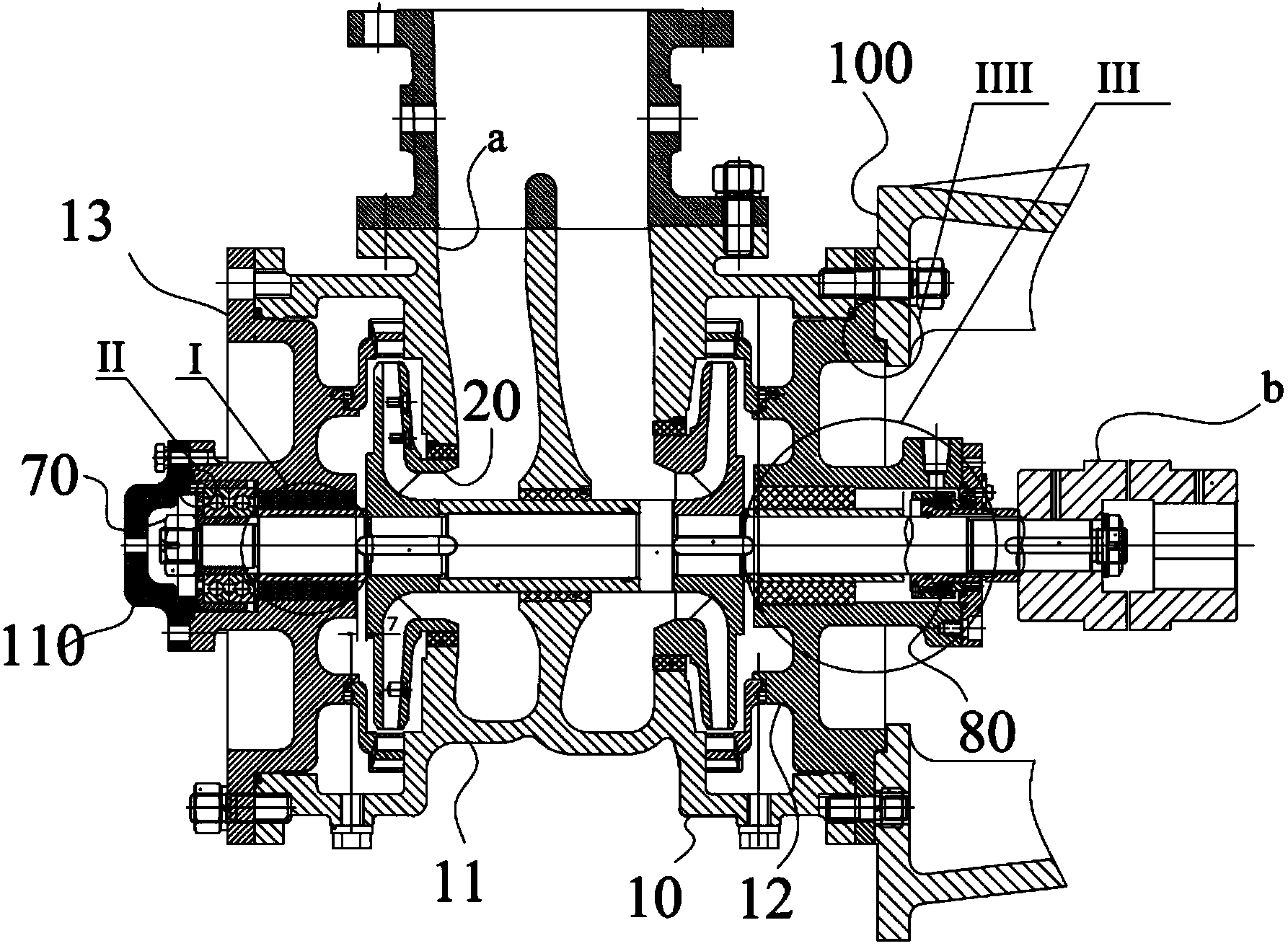

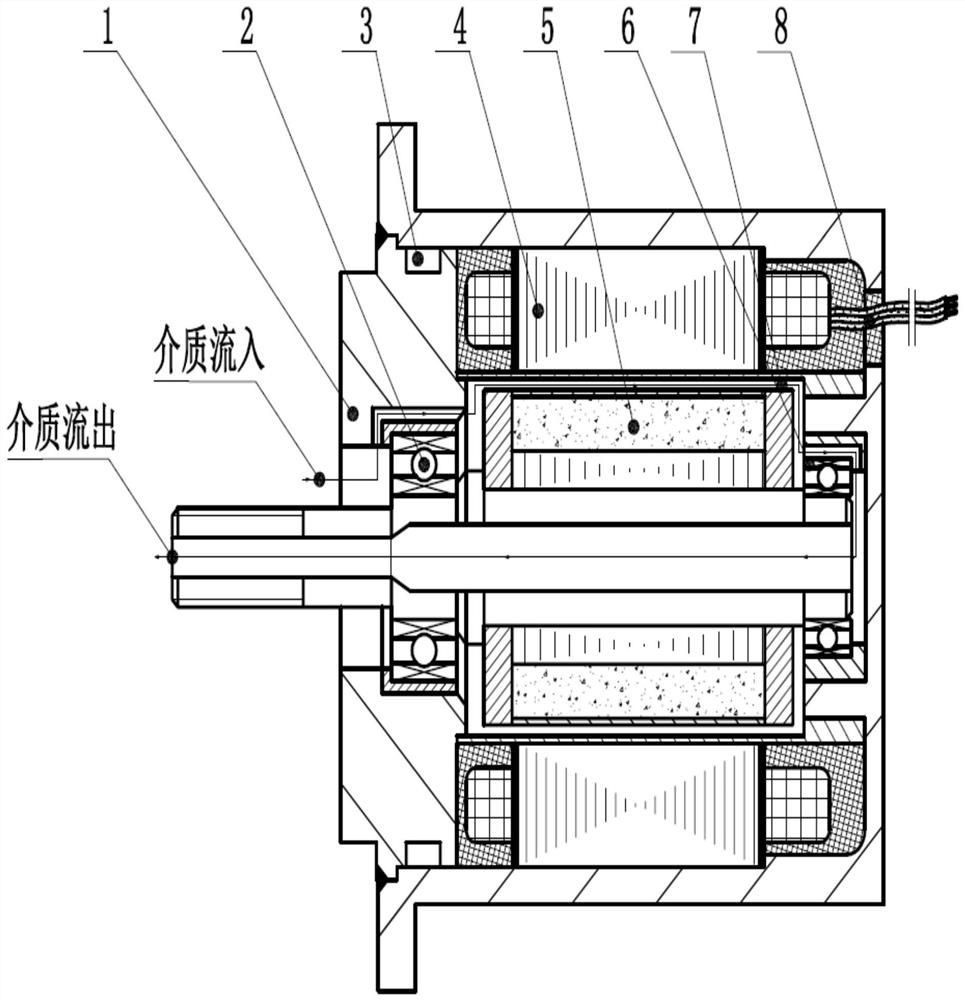

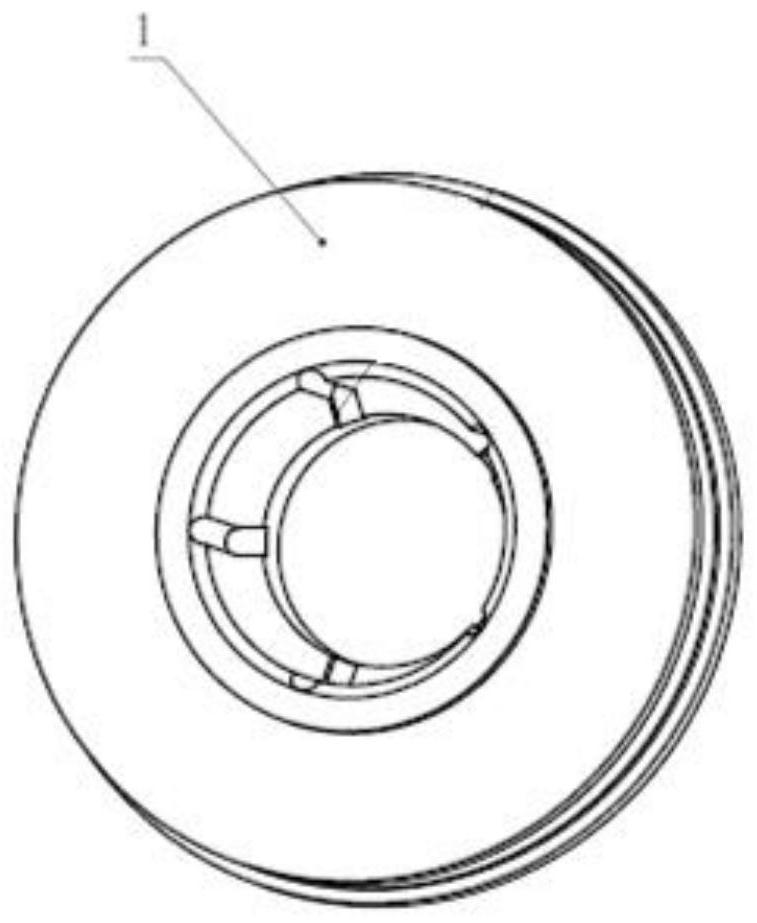

Centrifugal pump with self-lubricating bearing and self-centering function

InactiveCN103527507AAchieve self-lubricating effectGuaranteed smoothnessPump componentsPumpsCentrifugal pumpEngineering

The invention belongs to the field of pump units, and particularly relates to a centrifugal pump with a self-lubricating bearing and a self-centering function. The centrifugal pump comprises a pump case, a pump impeller, a pump shaft and a driving source, wherein the pump impeller is used for driving a medium in the pump case to flow in a set direction, the pump shaft is used for driving the pump impeller to rotate, and the driving source is at least located at one end of the pump shaft and used for driving the pump shaft to rotate. A pump cavity is formed in the pump case and used for circulation of the medium, the pump shaft penetrates through a pump case body, and the pump impeller on the pump shaft is arranged to be contained in the pump cavity. The centrifugal pump further comprises a bearing assembly used for supporting the pump shaft, and a channel is formed between the position to be lubricated on the bearing assembly and the pump cavity and used for connecting the position to be lubricated and the pump cavity and for circulation of the medium. Liquid state fluidity of the medium self is used for achieving the self-lubricating effect of the bearing assembly, processing technologies of the centrifugal pump are reduced to the great degree, so that the effect of simplifying assembly structures of the centrifugal pump is achieved, and the centrifugal pump is simple in structure, good in stability and high in working reliability.

Owner:WUHAN HAIWANG TECH +2

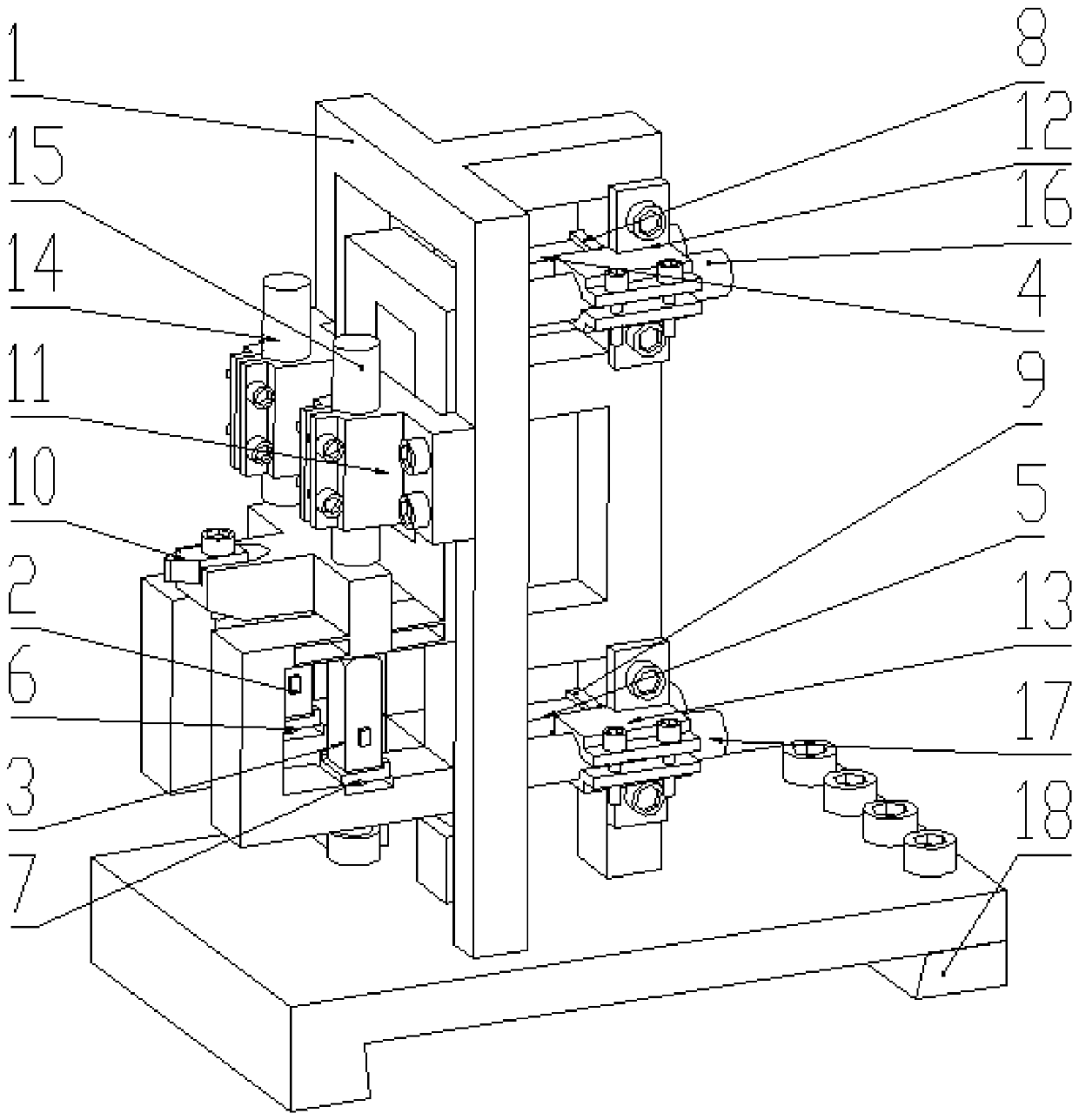

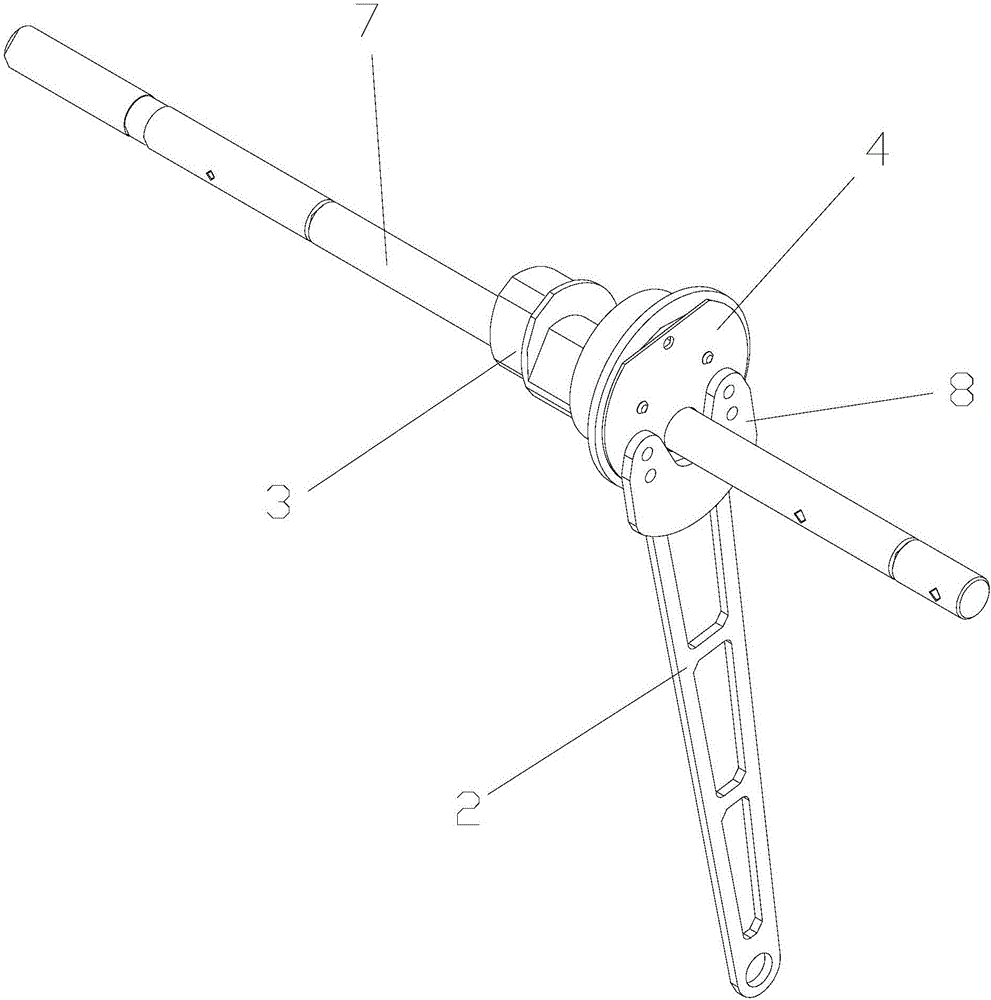

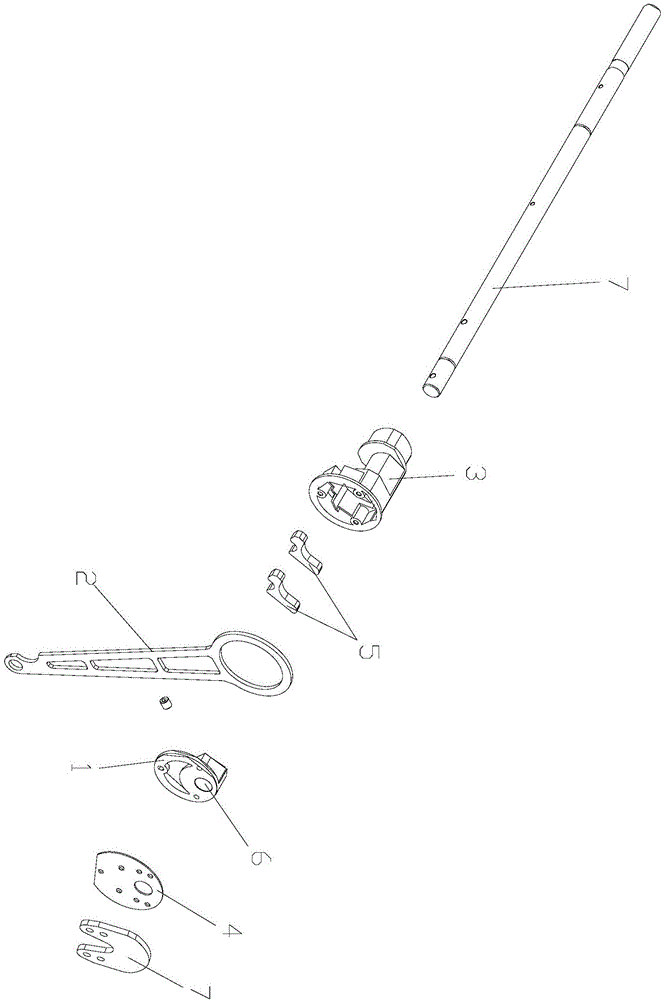

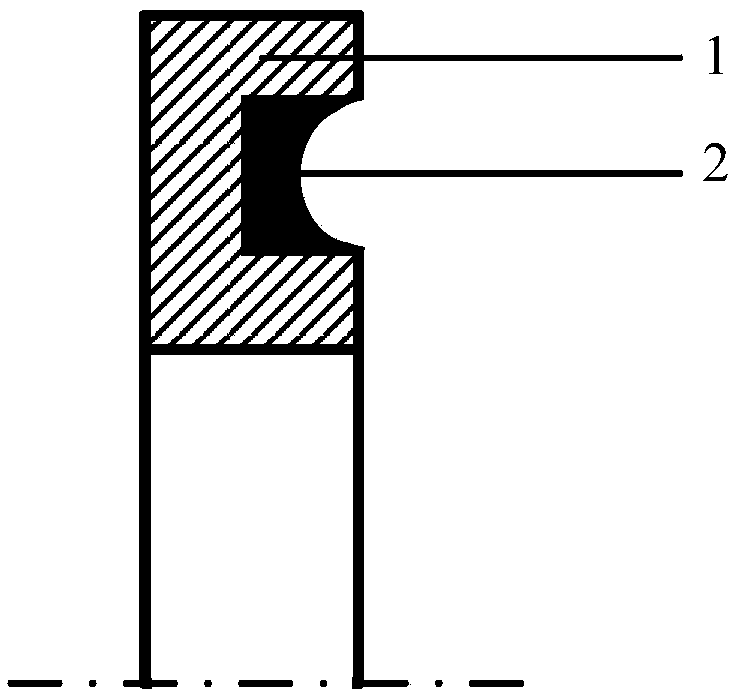

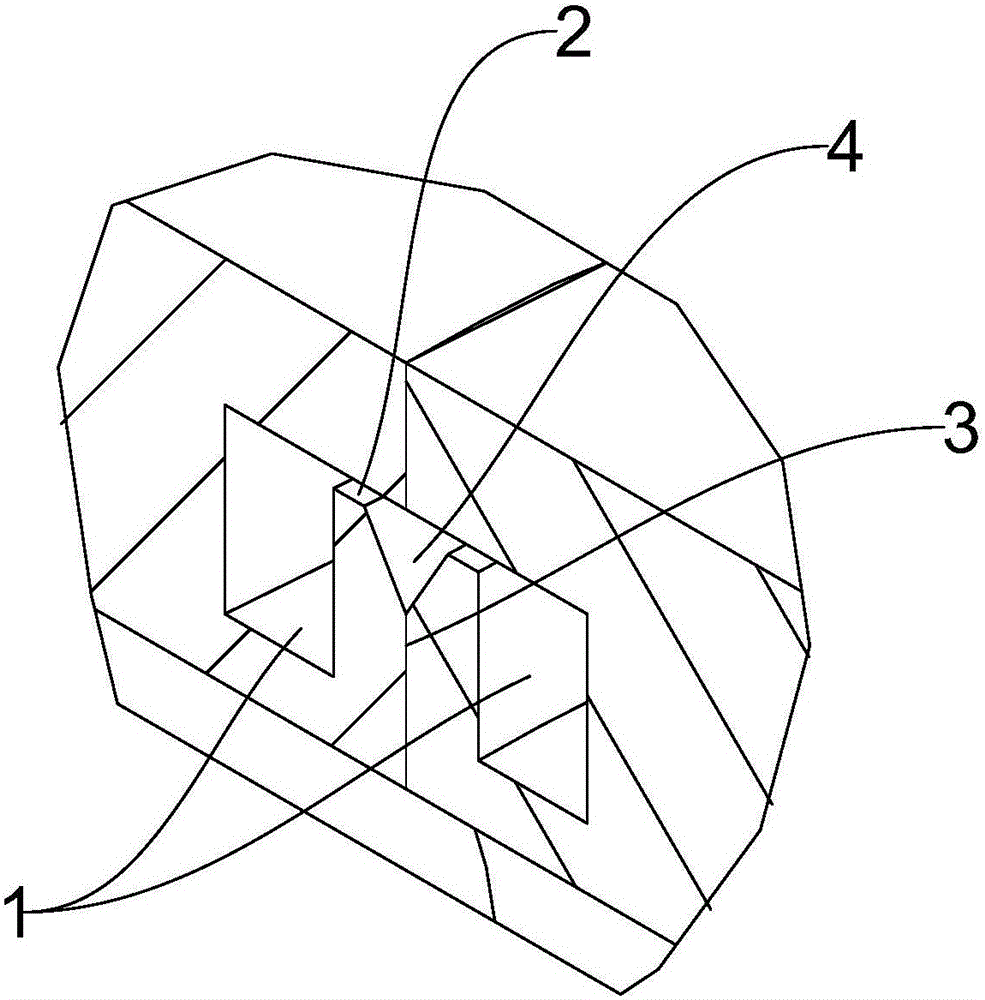

Axial sliding mechanism

InactiveCN103307119APromote research and developmentReduce R&D costsLinear bearingsBearing unit rigid supportEngineeringLubrication

The invention discloses an axial sliding mechanism and relates to the field of sliding mechanisms, aiming to solve the problems of complex structure, tedious processing, difficulty in control, too high cost, and greasy dirt pollution of the axial sliding mechanism. The mechanism comprises a shaft (1), a shaft sleeve (2), a lubricating ring sleeve (3) and an annular groove (4), wherein the lubricating ring sleeve (3) is sleeved on the exterior of the shaft (1) and is an open ring structure, the external diameter of the lubricating ring sleeve (3) in a natural open state is larger than the internal diameter of the shaft sleeve (2), and the annular groove (4) is also can be formed in the shaft (1); the lubricating ring sleeve (3) is embedded in the annular groove (4), and the lubricating ring sleeve (3) is made of a self-lubrication material and can be made of teflon or nylon. The axial sliding mechanism disclosed by the invention is applicable to various precision equipment or instruments.

Owner:SHANGHAI MEDIWORKS PRECISION INSTR CO LTD

A kind of self-lubricating bearing and its preparation method

ActiveCN107460475BAchieve self-lubricating effectExtend your lifeMetallic material coating processesHigh surfaceTitanium carbide

The invention discloses a self-lubricating bearing and a preparation method thereof. According to the self-lubricating bearing, chromium-containing alloy steel is used as a matrix, the working surface of the matrix is a graphene / calcium fluoride / ceramic self-lubricating coating, the coating comprises 30%-50% of nickel-coated aluminum oxide, 20%-40% of nickel-coated silicon nitride, 5%-8% of aluminum-oxide-coated graphene, 5%-8% of aluminum-oxide-coated calcium fluoride, 20%-30% of titanium carbide and 0.5%-2% of nickel, and the sum of weight percentages of all powder is 100%. Graphene and calcium fluoride powder are added in ceramic mixed powder, and the self-lubricating coating is formed on the surface of the matrix material in a fusion covering manner by a laser synchronous powder feeding mode. In the self-lubricating bearing prepared by the method, the binding force between the metal matrix and the self-lubricating coating is large; and meanwhile, the self-lubricating bearing has the characteristics of high surface hardness, good wear resistance and the like. In the working process, a continuous solid lubricating film can be formed on the working surface by means of the self-lubricating coating, and therefore, the self-lubricating function of the bearing is fulfilled.

Owner:SOUTHEAST UNIV

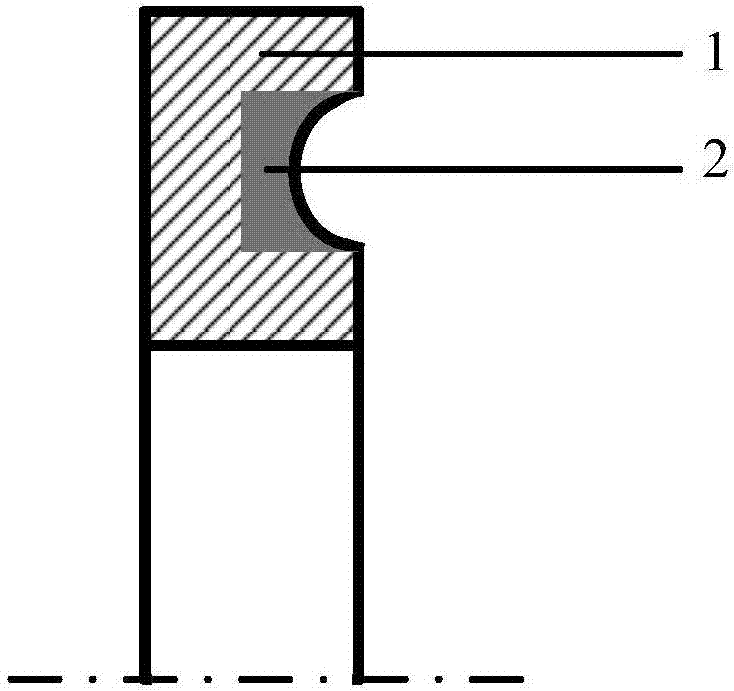

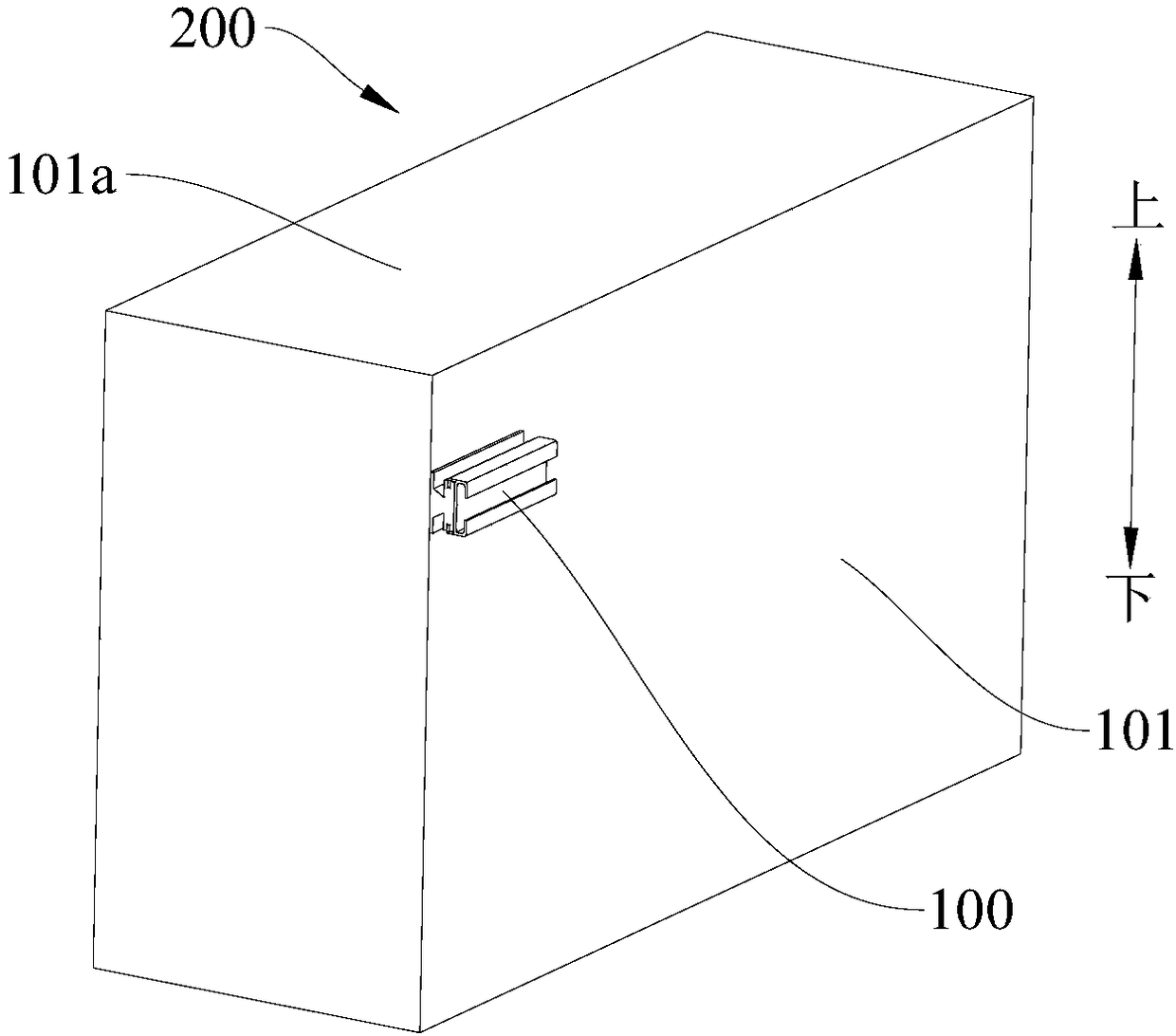

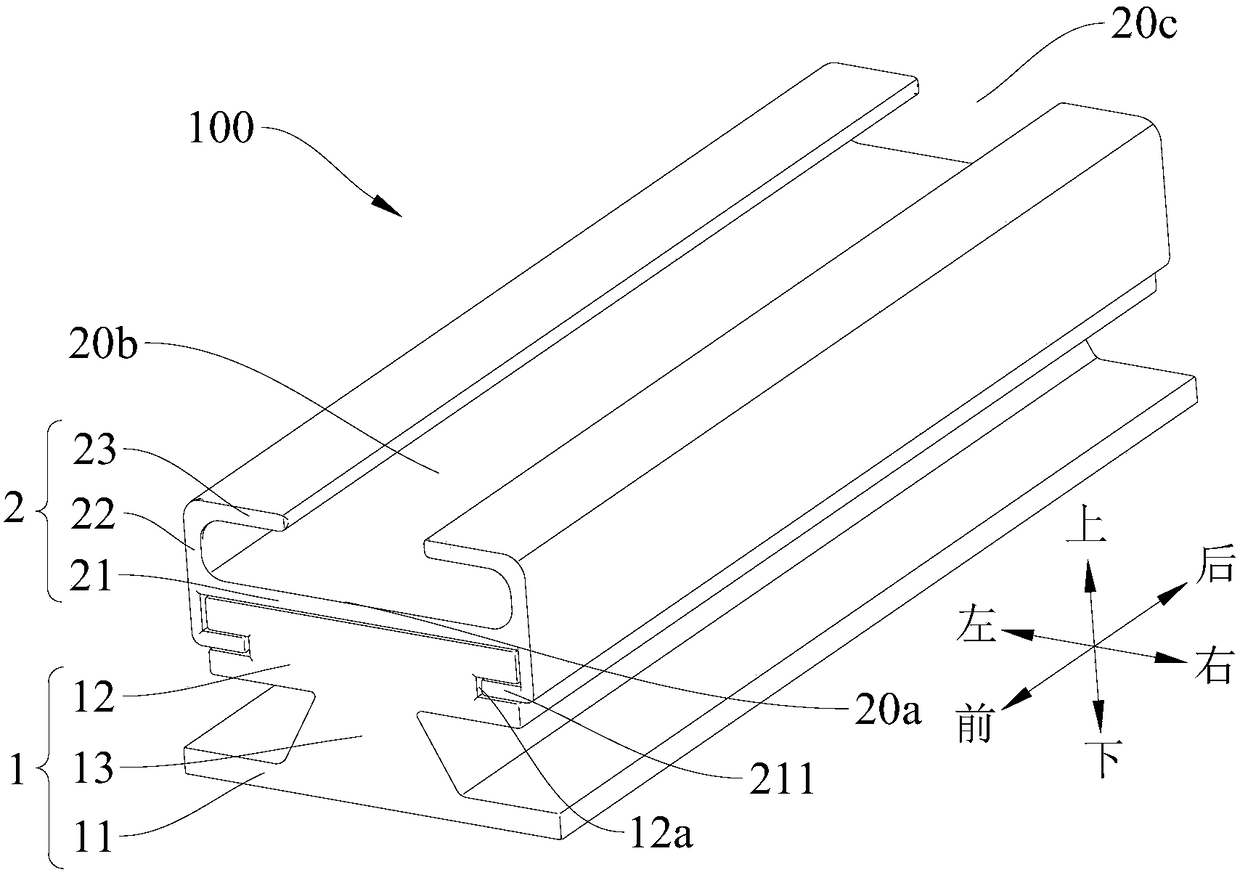

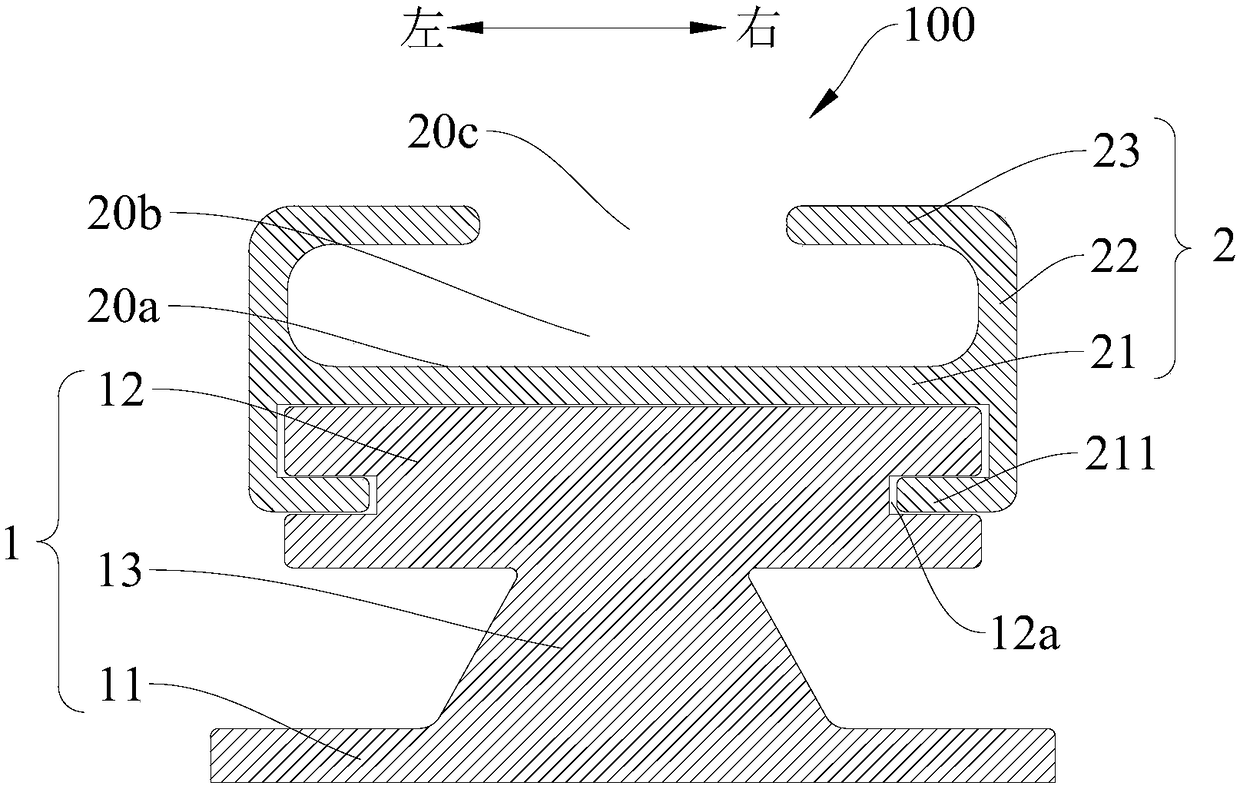

Conductor rail for straddle type monorail and straddle type monorail with conductor rail

The invention discloses a conductor rail for a straddle type monorail and the straddle type monorail with the conductor rail. The conductor rail for the straddle type monorail comprises a base and a steel belt arranged on the base. A concave part is arranged on the surface of the side, away from the base, of the steel belt. A groove is defined in the concave part, the concave part is provided withan opening which communicates with the groove and is open towards the direction away from the base, and the width of the opening is smaller than that of the groove. According to the conductor rail for the straddle type monorail, the concave part is arranged on the steel belt to define the groove and the opening which communicates with the groove and is open towards the direction away from the base, and the width of the opening is smaller than that of the groove, so that when the conductor rail is applied to the straddle type monorail to be used for train operation, a carbon contact strip is prevented from being separated from the conductor rail from the opening due to being located in the groove, and then the arc discharge phenomenon is avoided and normal train operation is guaranteed; and meanwhile, good environment protection performance is achieved, and the self-lubricating effect is achieved.

Owner:BYD CO LTD

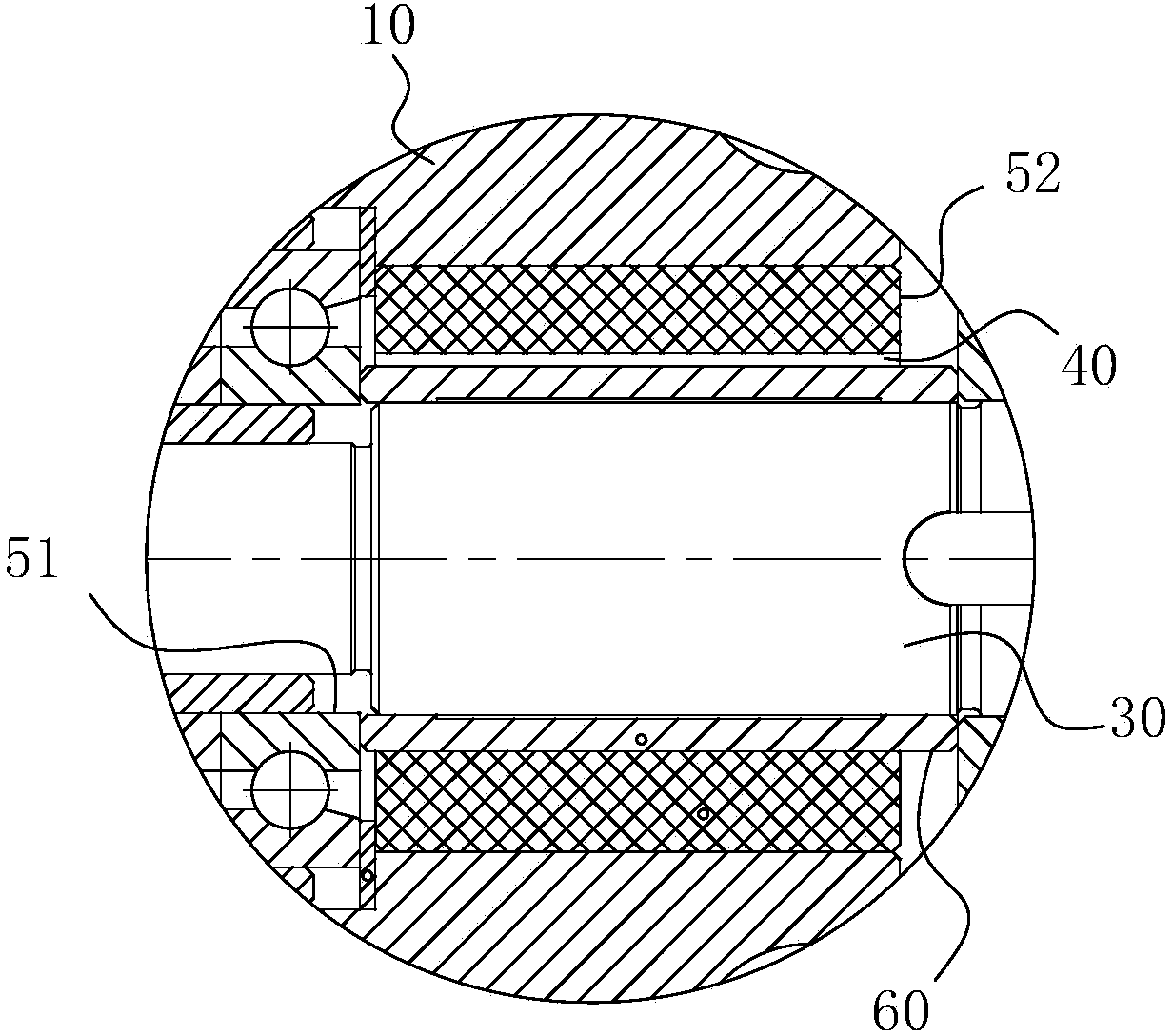

Micro permanent magnet motor for liquid cooling pump

ActiveCN113765283AReduce weightImprove efficiencyMagnetic circuit stationary partsMechanical energy handlingElectric machineFriction loss

The invention particularly relates to a micro permanent magnet motor for a liquid cooling pump, and solves the structural design problems of large friction loss, large mechanical gap, low efficiency, insufficient structural strength and weak resistance to radial impact force of a traditional micro liquid cooling pump motor sealing element. The micro permanent magnet motor for the liquid cooling pump comprises an end cover assembly, a casing, a stator assembly and a rotor assembly. The end cover assembly and the casing are fixedly and hermetically connected to form a stator and rotor mounting cavity; the stator assembly is located in the stator and rotor mounting cavity and comprises a stator sheath and a stator armature which are coaxially arranged in sequence from inside to outside; and the rotor assembly comprises a motor shaft, and comprises a rotor core, magnetic steel and a rotor sheath which are positioned in the stator and rotor mounting cavity and are coaxially arranged on the motor shaft in sequence from inside to outside. According to the invention, the first flow channel is arranged on the end cover assembly, the second flow channel is arranged on the rear lining, the third flow channel is arranged in the motor shaft, the three flow channels are matched with the gaps for use, the flow resistance of cooling liquid in the motor is reduced, and the efficiency of the motor is improved.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

A kind of wear-reducing protective coating with hard and tough substrate surface and preparation method thereof

ActiveCN107354442BHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingSputteringNanocrystal

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

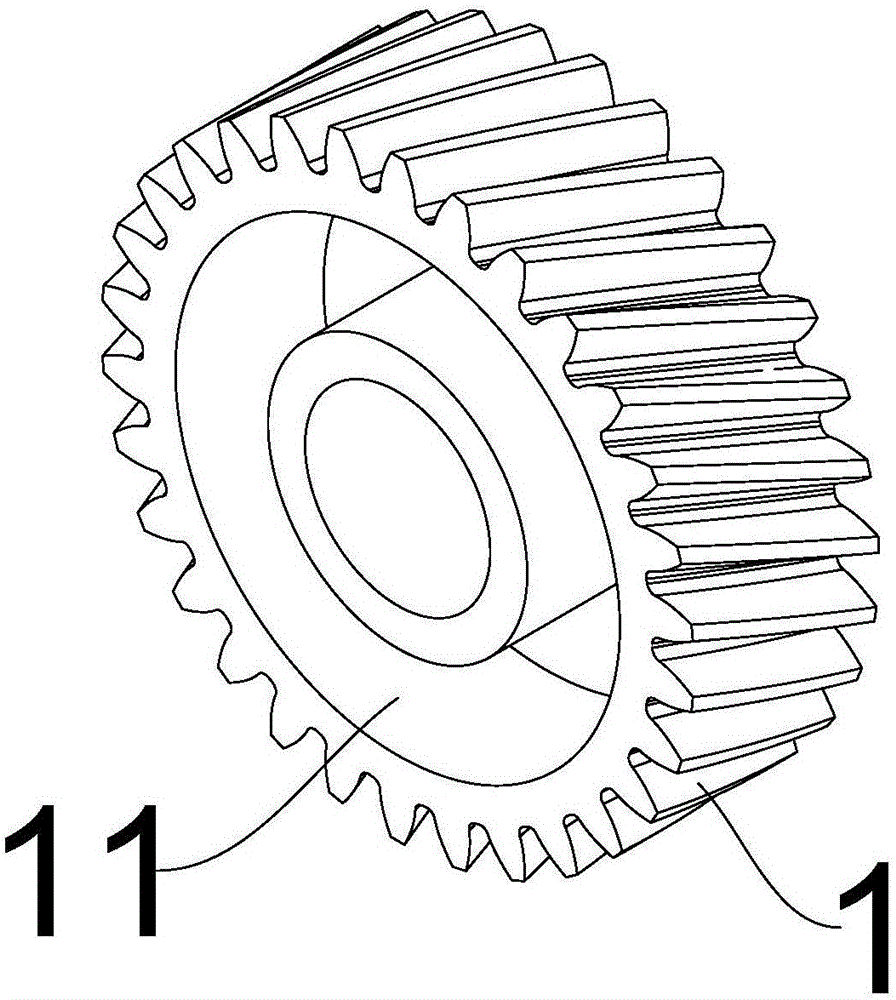

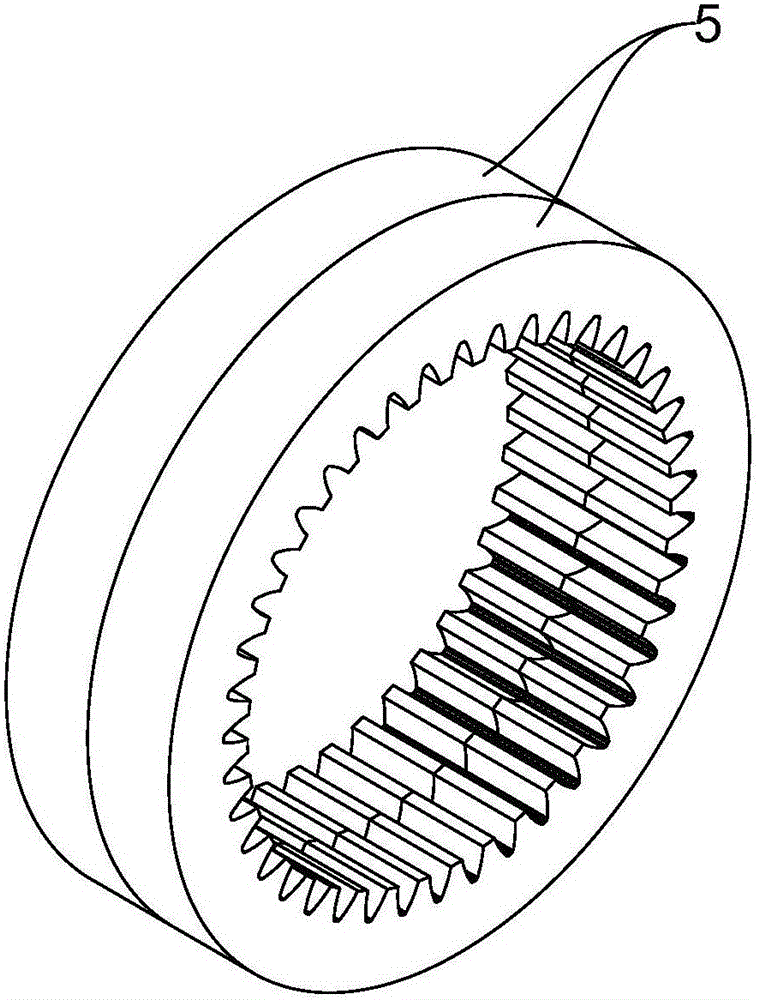

Inner gear with inner oil storage chambers

InactiveCN105952877AAchieve self-lubricating effectPortable liftingGear lubrication/coolingOil canCentral plane

The invention discloses an inner gear with inner oil storage chambers, which adopts the structure that teeth are formed in the inner surface of the inner gear; the two circular oil storage chambers, two oil outlet passages and an oil outlet seam are formed in the inner gear; the oil outlet seam is formed in the central plane of the inner gear; one end of each oil outlet passage communicates with the outer end of the corresponding circular oil storage chamber, and the other end of the oil outlet passage communicates with one end of the oil outlet seam; the other end of the oil outlet seam communicates with the teeth; and the two circular oil storage chambers are formed in two sides of the oil outlet seam, and are filled with lubricating oil. The inner gear disclosed by the invention has the advantage that the two circular oil storage chambers are formed in the inner gear, so that when the inner gear rotates, the lubricating oil can be pumped to the teeth through the oil outlet seam continuously and slowly to achieve the purpose of self-lubricating.

Owner:TAIZHOU JINXIN MACHINERY

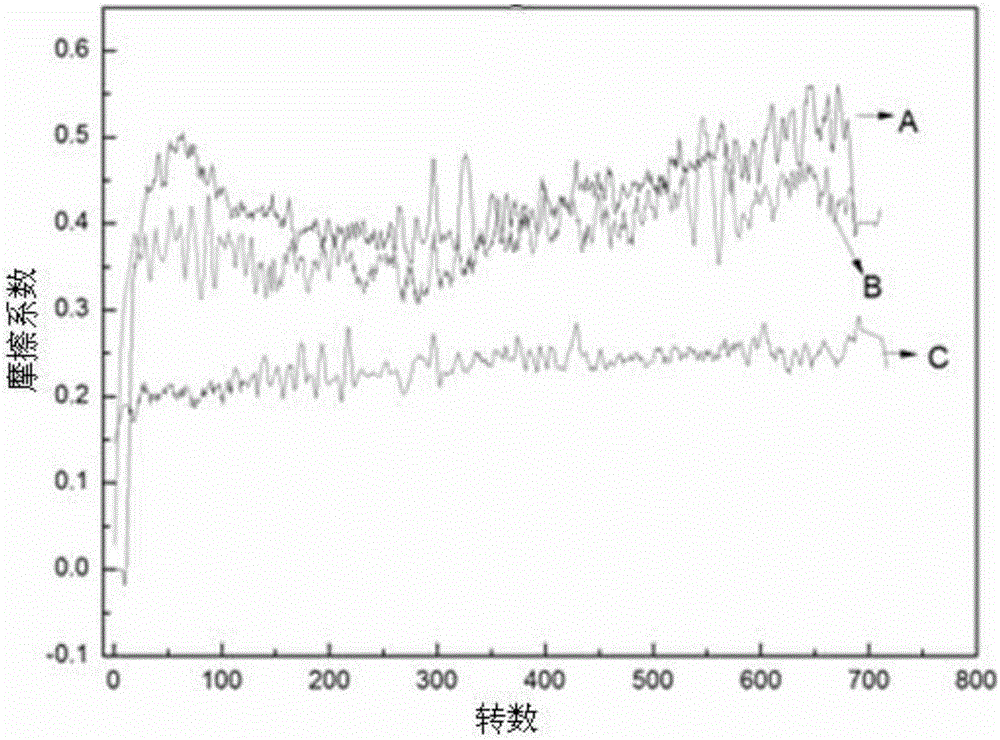

Laminated self lubricating ceramic wire pulling mold and preparation method thereof

InactiveCN109226299AGuaranteed structural strength requirementsOvercoming disadvantages of weakened strengthDrawing diesManufacturing technologyWorking life

The invention belongs to the technical field of metal wire pulling mold manufacturing, and relates to a laminated self lubricating ceramic wire pulling mold and a preparation method thereof. A base body material of the laminated self lubricating ceramic wire pulling mold is shard-hardness structure ceramic; the mold is formed by alternately overlapping basic layers and lubricating layers in the pulling work direction; the basic layers ensure the structure intensity of the whole of the mold; the lubricating layer provides the lubrication function of the pulling production. The laminated self lubricating ceramic wire pulling mold is prepared through the processes of layered lamination material laying, hot pressing sintering, diamond ultrafine milling hole making and the like. The wire pulling mold can be widely applied to dry type pulling processing of high-toughness metal wire materials; the serious friction and abrasion work conditions of a pulling work interface can be effectively avoided, so that the surface quality of the wire material production can be obviously improved; the work life of the wire pulling mold can be obviously prolonged; simplicity, convenience, high efficiency, energy saving and environment protection are realized.

Owner:SOUTHEAST UNIV

Self-lubricating ceramic composite material with biomimetic structure and preparation method thereof

ActiveCN102092164BEffect on mechanical propertiesAchieve self-lubricating effectCeramic layered productsCeramic compositeHexagonal boron nitride

The invention discloses a self-lubricating ceramic composite material with a biomimetic structure and a preparation method thereof. The composite material has a structure which is alternately laminated by ceramic layers and lubricating layers, wherein the ceramic layer is ZrO2, Al2O3, or ZrO2-Al2O3, and the lubricating layer is made of graphite, molybdenum disulfide, or hexagonal boron nitride. The composite material has excellent friction and abrasion performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

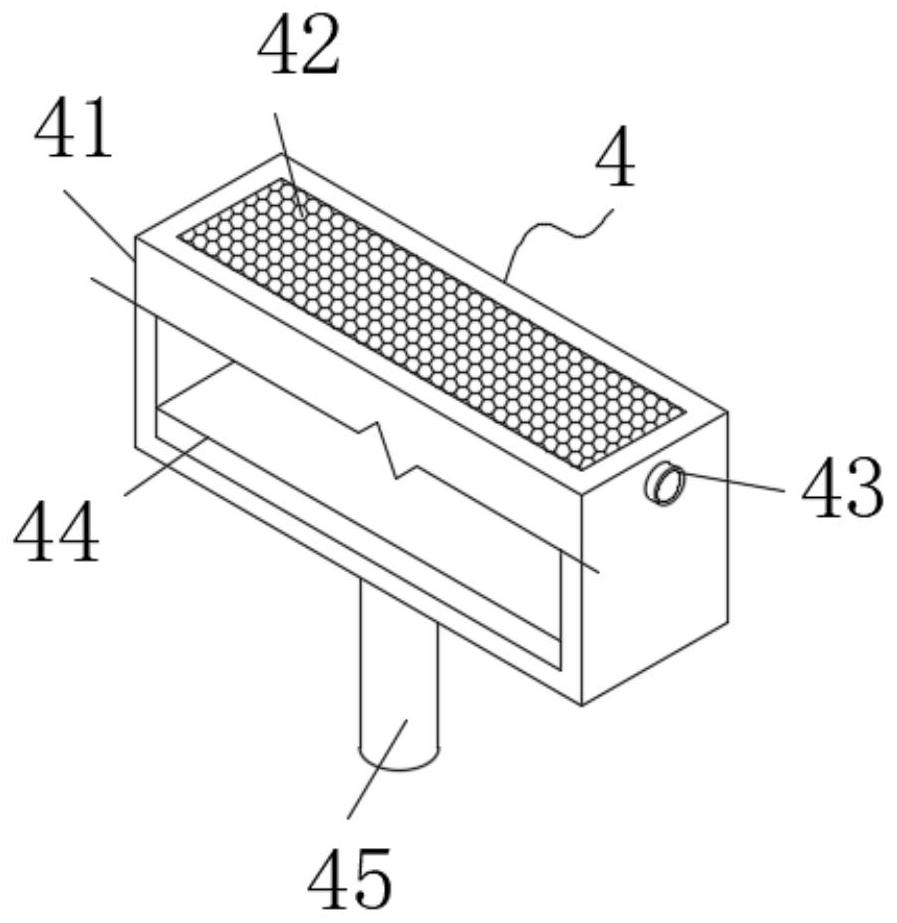

A ball transmission device for machine tool processing

ActiveCN113510532BReduce laborReduce wearFeeding apparatusMaintainance and safety accessoriesEngineeringMachine tool

The invention discloses a ball transmission device for machine tool processing, which comprises a machine body, a power mechanism and a cover plate. On the corresponding two sides inside the body and close to the top position, the screw drive device is set between the corresponding two sides of the inner wall of the body and close to the position of the pressing oil supply device, and the conical funnel is set inside the body and located on the screw drive device The bottom position, the oil storage tank is arranged at the bottom of the inner wall of the machine body and communicates with the bottom end of the conical funnel. The invention relates to the technical field of machine tool equipment. The ball transmission device for machine tool processing achieves the effect of automatic lubrication, which can automatically lubricate the ball transmission mechanism without manual manual lubrication and maintenance, which reduces the amount of manual labor, saves time and effort, and reduces wear during transmission. It helps to prolong the service life of the equipment, is safe and reliable, and improves the performance.

Owner:启东市万润机床附件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com