Self-lubricating bevel gear provided with oil storage cavity

A technology of bevel gears and oil storage chambers, applied to components with teeth, belts/chains/gears, gear lubrication/cooling, etc., can solve the problem of reducing the strength of bevel gears, and the teeth cannot be lubricated and oiled out The small hole is easy to be blocked and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

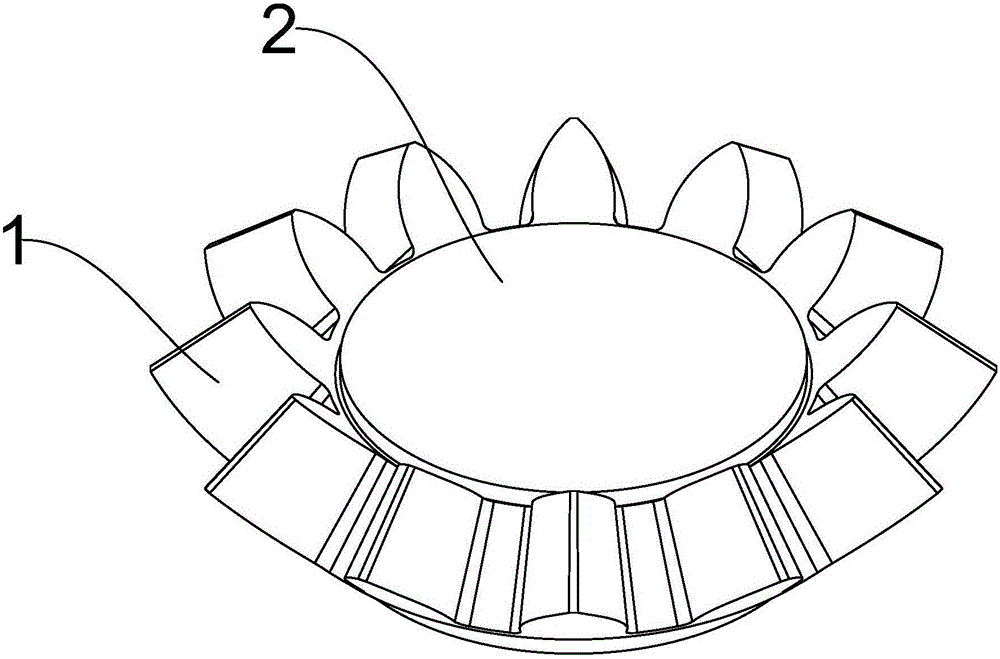

[0020] Such as figure 1 As shown, a self-lubricating bevel gear with an oil storage chamber includes a bevel gear body 1 and an oil distribution cover 2,

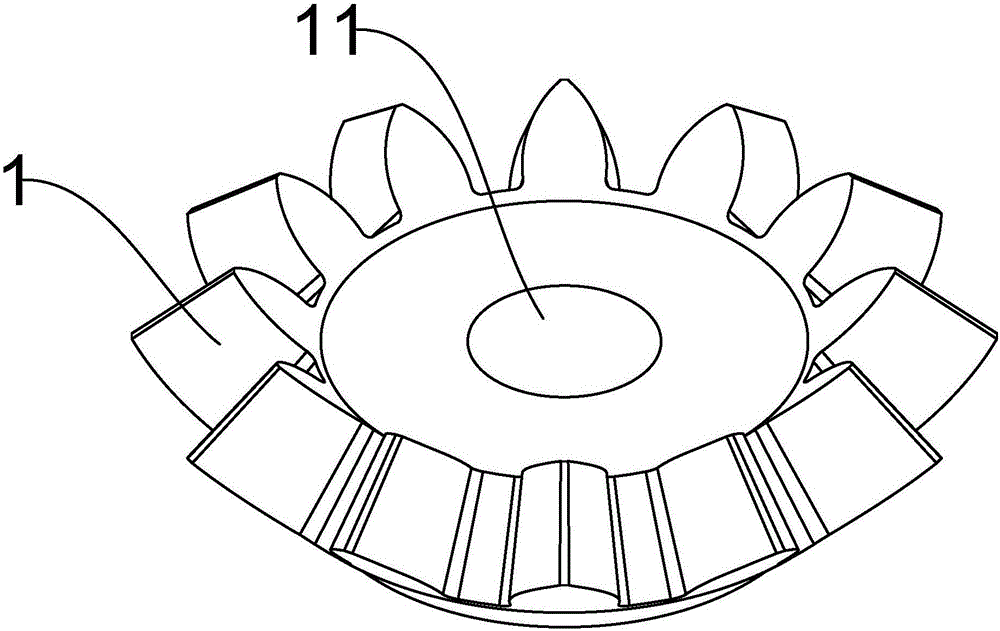

[0021] Such as figure 2 As shown, the center of the top of the bevel gear body 1 is provided with an oil storage chamber 11, the oil storage chamber 11 is cylindrical, and the end is provided with internal threads; the oil storage chamber 11 is filled with lubricating oil;

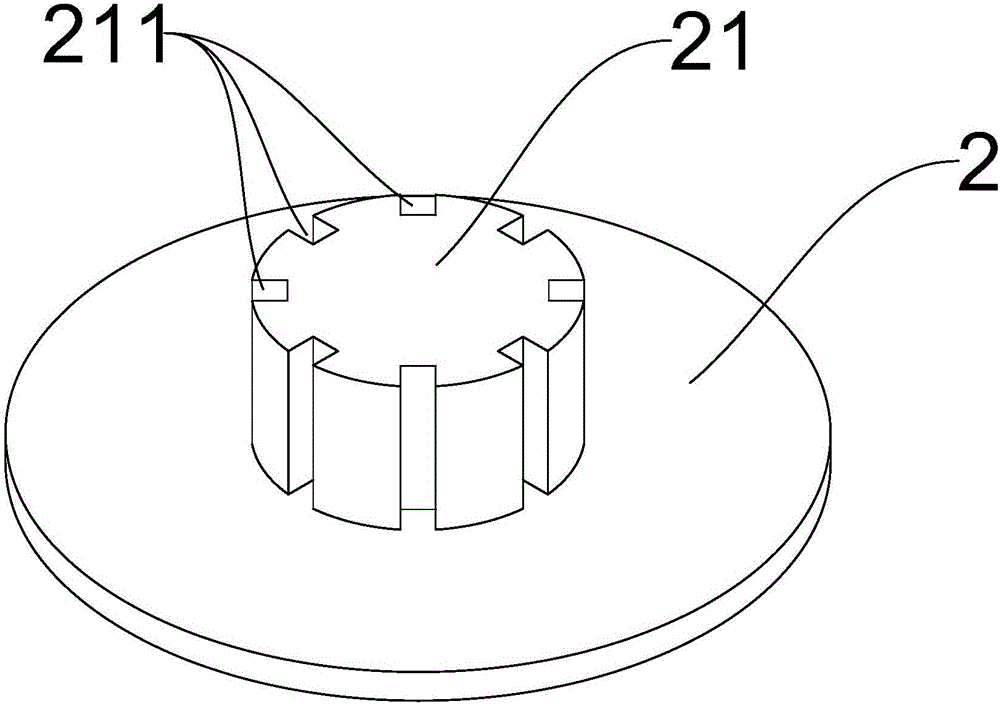

[0022] Such as image 3 As shown, the oil distribution cover 2 has a circular structure; the bottom of the oil distribution cover 2 is provided with a plunger 21, and the surface of the plunger 21 is uniformly provided with a plurality of oil outlet grooves 211, and the oil outlet grooves 211 are arranged along the column. The central axis of the plug 21 is evenly distributed and the central axis of the oil outlet groove 211 and the plunger 21 are parallel to each other, and the oil outlet groove 211 runs through both ends of the plunger 21;

[0023...

Embodiment 2

[0027] On the basis of the first embodiment, the edge of the oil separator plate 2 is pressed against the tooth root of the bevel gear body 1 . By designing the diameter of the oil-separating cover plate 2, its edge can be pressed on the tooth root, so that its edge can be lifted slightly, so that the gap between the position closer to the edge on the oil-separating cover plate 2 and the end surface of the bevel gear body 1 The larger the , the resistance to the flow of lubricating oil can be reduced to a certain extent, so that this self-lubricating bevel gear with an oil storage chamber can be applied to occasions with slower speeds; in the first embodiment, under the action of vibration , the plunger 21 is easy to fall off from the oil storage chamber 11, and the structure disclosed in the second embodiment can play a role similar to a gasket, which can greatly reduce the plunger 21 from the oil storage chamber 11. probability of falling out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com