Three-dimensional elliptical vibration flexible device based on metal porous material

A metal porous and elliptical vibration technology, used in metal processing equipment, tool holder accessories, turning equipment, etc., can solve the problem of machine tool guide rail affecting the motion accuracy, achieve the self-lubricating effect of the mechanism, avoid motion coupling, and ensure motion accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

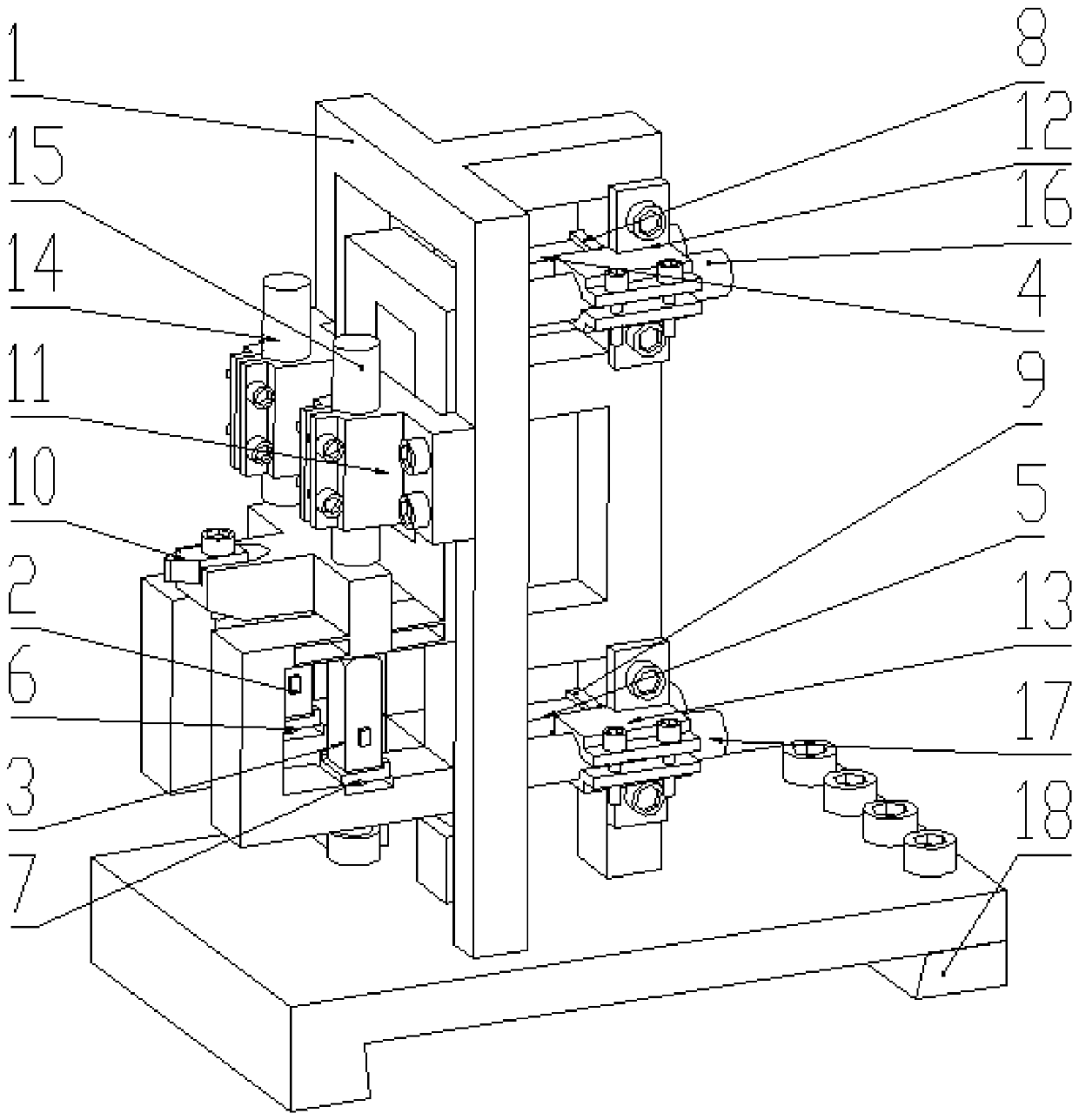

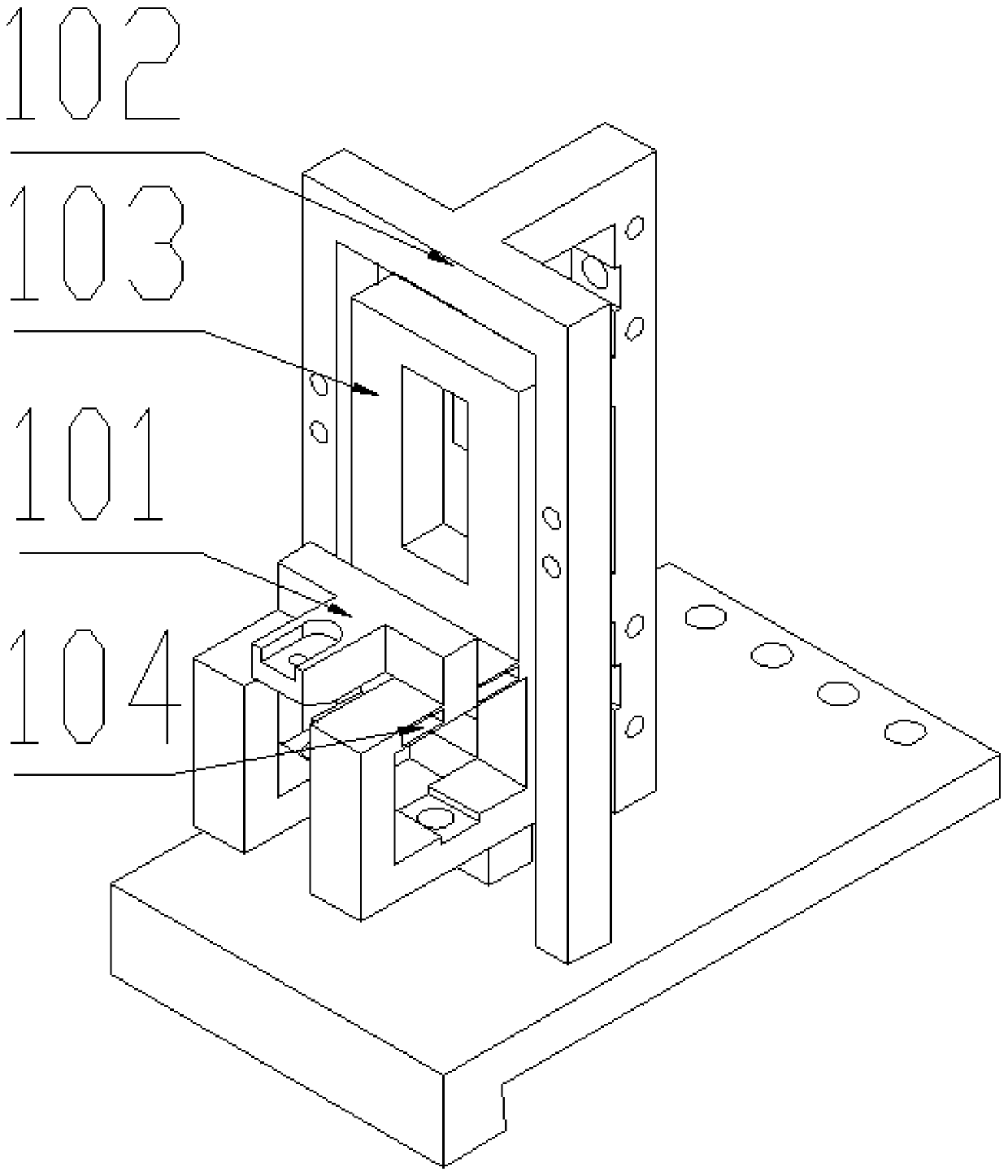

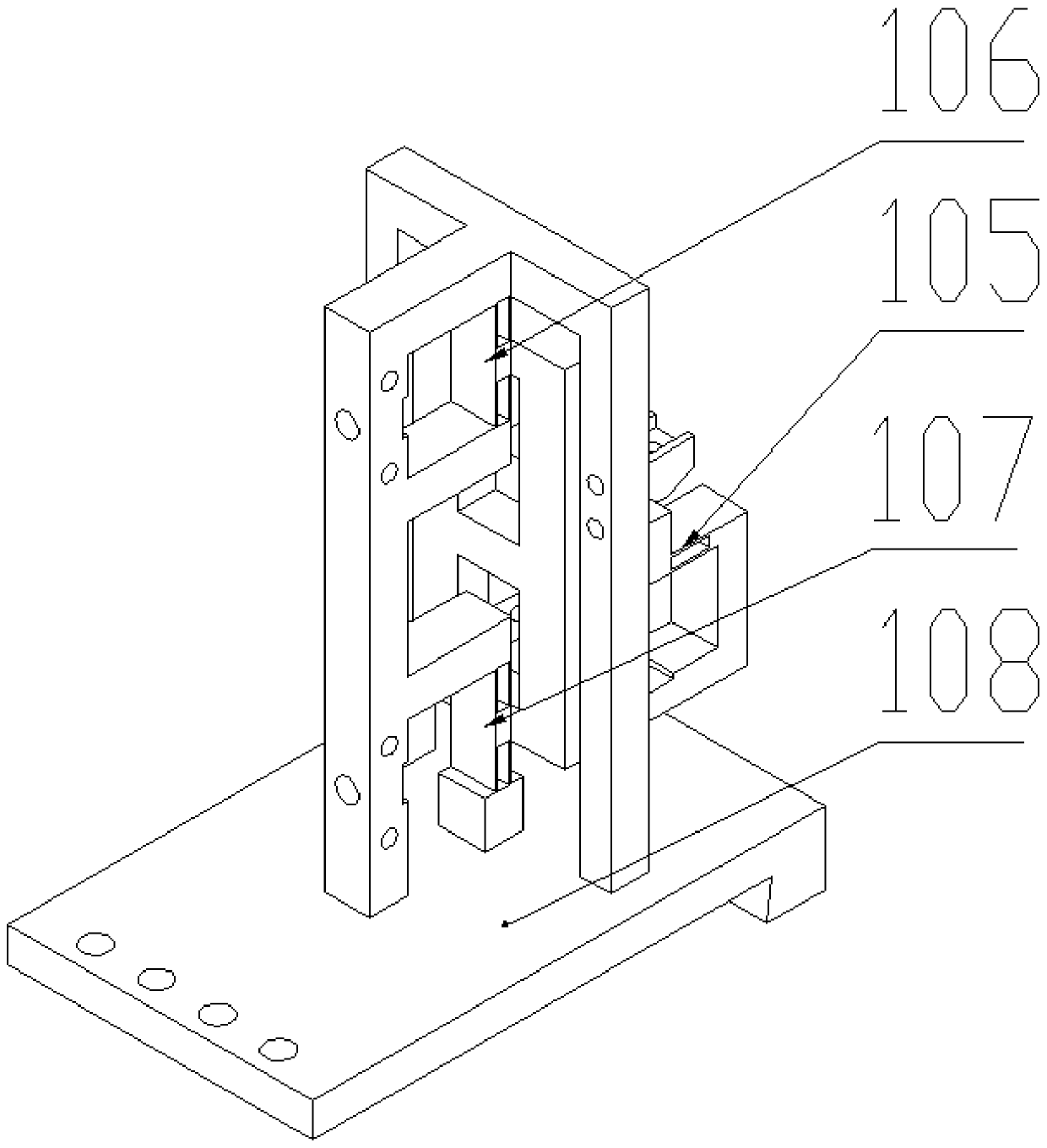

[0021] The tool 10 is fixed in the tool groove in the middle of the T-shaped tool seat 101 of the flexible substrate 1 by bolts, the vertical piezoelectric stack 1 2 and the vertical piezoelectric stack 2 3 are distributed in parallel, and each head is connected to the straight-type flexible Hinge 1 104 is in contact with straight flexible hinge 2 105, and the lower end is pre-tightened respectively by bolt-tightening pre-tightening block 1 6 and bolt-tightening pre-tightening block 2 7, and capacitive displacement sensor 1 14 and capacitive displacement sensor 2 15 are respectively clamped in the sensor clamp Hold one 11, the head of which is respectively aligned with the T-shaped tool seat surface 101, and the sensor clamp one 11 is fixed on the outer support 102; the horizontal piezoelectric stack one 4 and the horizontal piezoelectric stack two 5 are distributed in parallel, and the other The head is respectively in contact with the straight flexible hinge 3 106 and the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com