Constant-speed elliptical track laser precision machining method of oblique cone circular table

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The invention provides a constant-velocity elliptical trajectory laser precision machining method for an oblique conical frustum, which is suitable for the laser precision machining of an oblique conical frustum workpiece with an elliptic conic curve profile feature.

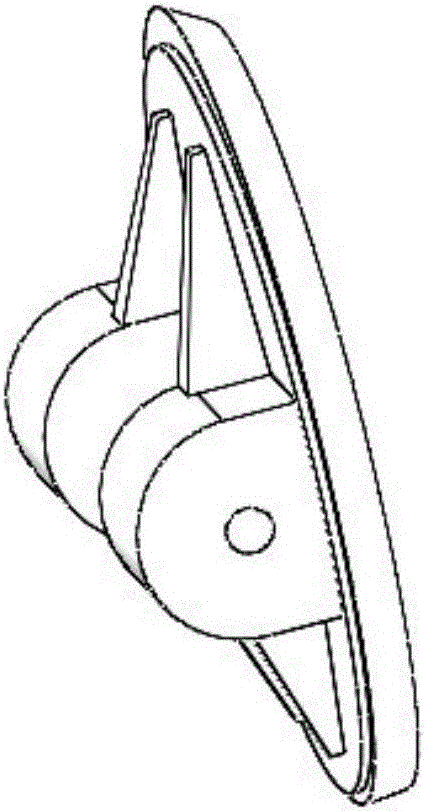

[0028] image 3 Shown is a typical oblique cone truncated workpiece, that is, a triple eccentric butterfly plate. Figure 4 Shown is a schematic diagram of clamping when processing a triple-eccentric butterfly plate. The triple-eccentric butterfly plate 5 is installed on the inclined table 3 through the clamping sleeve 4 , and the inclined table 3 is installed on the rotary table 7 through the three-jaw chuck 6 .

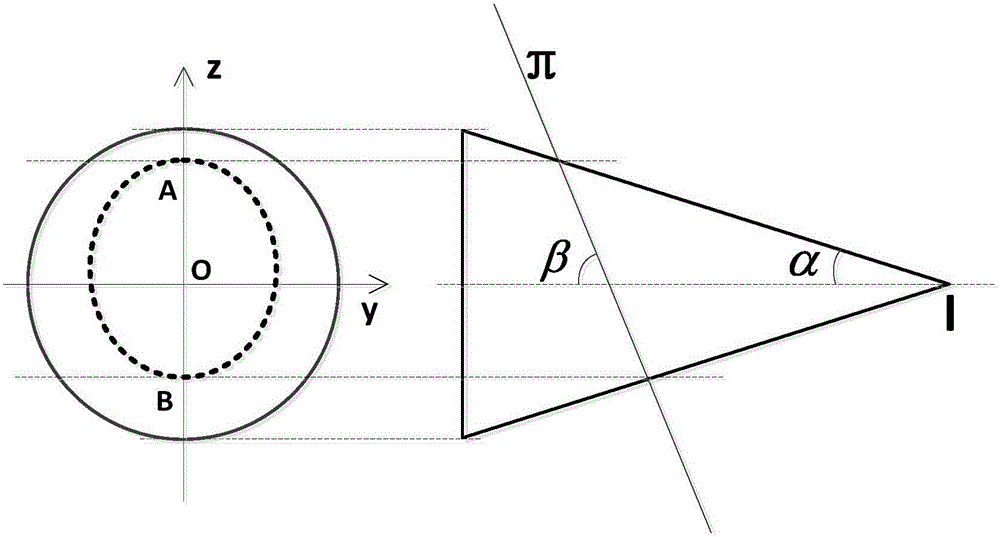

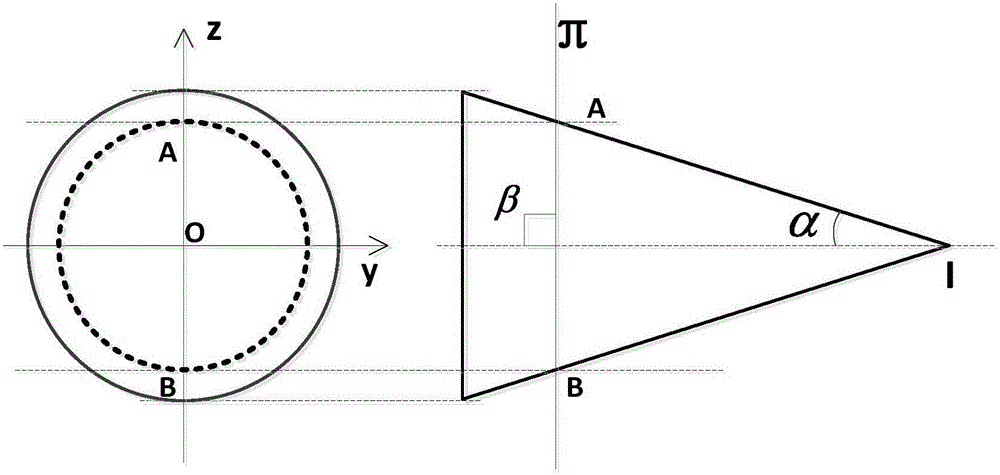

[0029] Without loss of generality, the present invention assumes that the oblique conical frustum workpiece to be processed is an oblique conical fru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com