Double-shaft positioner mechanical structure

A technology of mechanical structure and positioner, used in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low transmission accuracy, unsatisfactory requirements, complex structure, etc., and achieve accurate posture and simple structure. , increase the aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

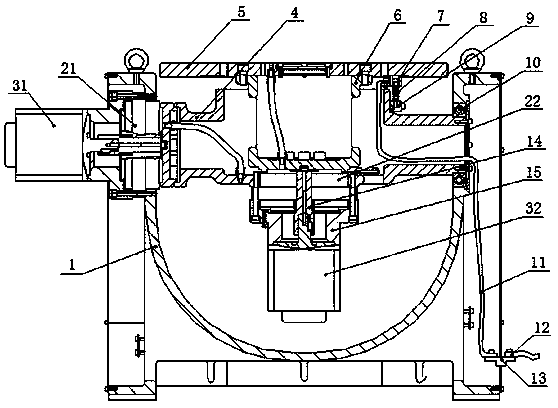

[0012] figure 1 Shown is a schematic diagram of the structure of the present invention.

[0013] The present invention includes a machine base 1, a horizontal servo motor 31, a horizontal RV reducer 21, a vertical servo motor 32 and a driven vertical RV reducer 22, a turning table 4, a work table 5, a rotating seat 6, a conductive block 7, and a spring 8 , Conductive seat 9, bearing 10, ground wire 11, welding machine ground wire 12, insulating seat 13, central gear 14, connecting piece 15.

[0014] The horizontal servo motor 31 drives the horizontal RV reducer 21, the horizontal RV reducer 21 is installed on the base 1, one end of the turning table 4 is installed on the output shaft of the horizontal RV reducer 21 through screws, and the other end is supported on the machine. On the bearing 10 of the base 1, when the horizontal servo motor 31 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com