Axial sliding mechanism

An axial sliding and bushing technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of difficult to control sliding damping, high processing cost, complex structure, etc., to shorten the research and development time, reduce research and development costs, convenient The effect of research and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation method of the axial sliding mechanism of the present invention will be described in detail below in conjunction with the accompanying drawings.

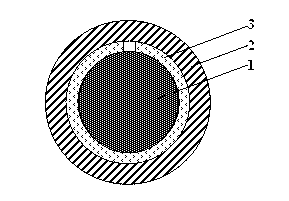

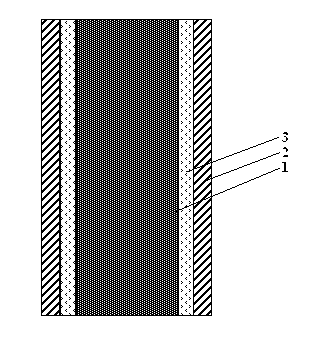

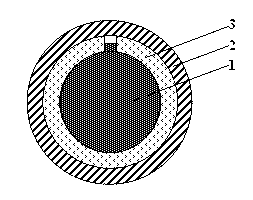

[0030] figure 1 In the transverse cross-sectional view of the general embodiment of the present invention, the mechanism includes a shaft 1, a shaft sleeve 2, and a lubricating ring sleeve 3, the lubricating ring sleeve 3 is set outside the shaft 1, and the lubricating ring sleeve 3 is an open-loop structure; The outer diameter of the lubricating ring sleeve 3 in a naturally opened state is larger than the inner diameter of the shaft sleeve 2 . The lubricating ring 3 is made of self-lubricating material; the lubricating ring 3 can be made of polytetrafluoroethylene or nylon.

[0031] In fact, when the lubricating ring sleeve 3 is sleeved on the outside of the shaft 1, it is integrally sleeved on the outside of the shaft 1; before assembly, the outer diameter of the lubricating ring sleeve 3 when it is natur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com