High-strength self-lubricating polyurethane piston sealing body and preparation method thereof

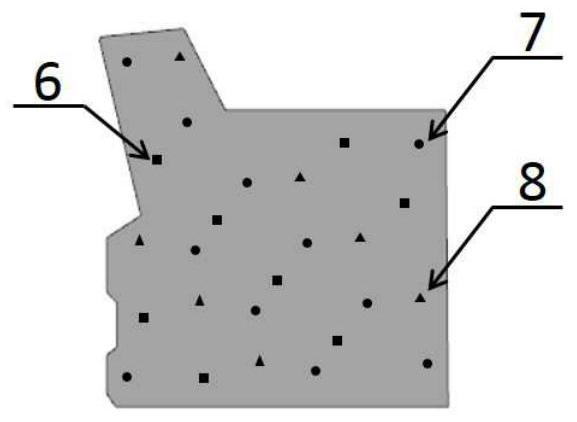

A polyurethane prepolymer and sealing body technology, which is applied in the field of polymer materials, can solve the problems of high wear and low strength, and achieve the effects of enhanced wear-reducing particle distribution, low cost, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] (1) Take 2500g of ultra-high molecular weight polyethylene powder and put it into a mixed solution of saturated potassium permanganate solution and 50% concentration of nitric acid, heat to 80°C and stir for 30min, then filter out the powder, then repeatedly wash with deionized water, filter. After drying, add it to a high-speed mixer, adjust the speed to 1500rpm, adjust the temperature to 70°C, and add 7.5 grams of coupling agent KH550 dropwise for coupling treatment for later use;

[0087] (2) Take 750g of polytetrafluoroethylene powder and put it into the sodium naphthalene solution, make it fully submerged, and then stir. Repeatedly use tetrahydrofuran to wash and filter; dry in an oven for 150 hours, grind and disperse for later use;

[0088] (3) Take 250 grams of alumina powder and put it into a high-speed mixer, adjust the rotating speed to 2000 rpm, adjust the temperature to 70 ° C, and add 5 grams of coupling agent KH550 dropwise for coupling treatment for lat...

Embodiment 2

[0096](1) Take 1250g of ultra-high molecular weight polyethylene powder and put it into a mixed solution of saturated potassium permanganate solution and 50% concentration of nitric acid, heat to 80°C and stir for 30min, then filter out the powder, then repeatedly wash with deionized water, filter. After drying, add it to a high-speed mixer, adjust the speed to 1500rpm, adjust the temperature to 70°C, and add 7.5 grams of coupling agent KH550 dropwise for coupling treatment for later use;

[0097] (2) Take 500g of polytetrafluoroethylene powder and put it into the sodium naphthalene solution, make it fully submerged, and then stir. Repeatedly use tetrahydrofuran to wash and filter; dry in an oven for 150 hours, grind and disperse for later use;

[0098] (3) Take 250 grams of alumina powder and put it into a high-speed mixer, adjust the rotating speed to 2000 rpm, adjust the temperature to 70 ° C, and add 5 grams of coupling agent KH550 dropwise for coupling treatment for late...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com