Self-lubricating plunger pump

A plunger pump, self-lubricating technology, applied to piston pumps, pumps, multi-cylinder pumps, etc., to achieve compact structure, prolong life, and prevent liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

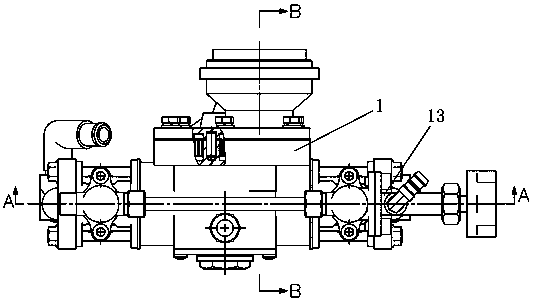

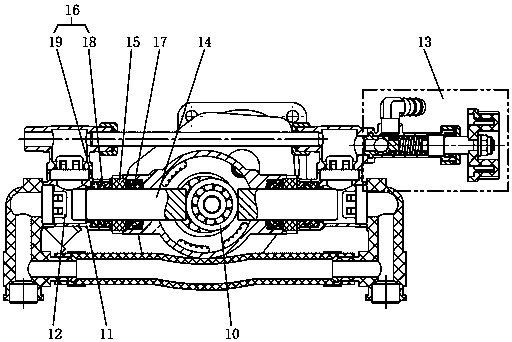

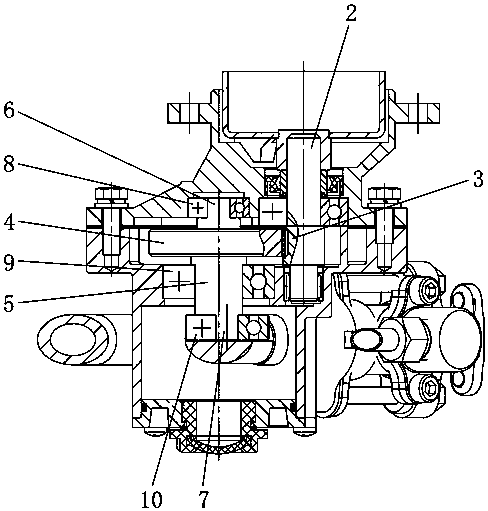

[0014] see Figure 1 to Figure 3 , the present invention provides a self-lubricating plunger pump, including a pump body 1, a power mechanism (not shown in the figure) connected to the pump body 1, the rotating shaft of the power mechanism (not shown in the figure) is connected and drives the first main shaft 2. Generally, the power mechanism is a motor, and the first main shaft 2 is fixed with a gear 3, the gear 3 meshes with the gear 2 4, and the gear 2 4 is fixed on the second main shaft 5, and the two ends of the second main shaft 5 The first sub-shaft 6 and the second sub-shaft 7 extend outward respectively, the first sub-shaft 6 and the second main shaft 5 are concentric, the second sub-shaft 7 and the second main shaft 5 are eccentric; the first sub-shaft 6. The first fixed bearing 8, the second fixed bearing 9 and the dynamic bearing 10 are set on the second main shaft 5 and the second auxiliary shaft 7 respectively, and the first fixed bearing 8 and the second fixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com