Oil-immersed water-proofing wire immersible motor for immersible pump and its making method

A technology of electric motor and waterproof wire, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of poor lubrication of bearings, reduced insulation strength of coils, unusable use, etc., to achieve good insulation, excellent insulation performance, and improved use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

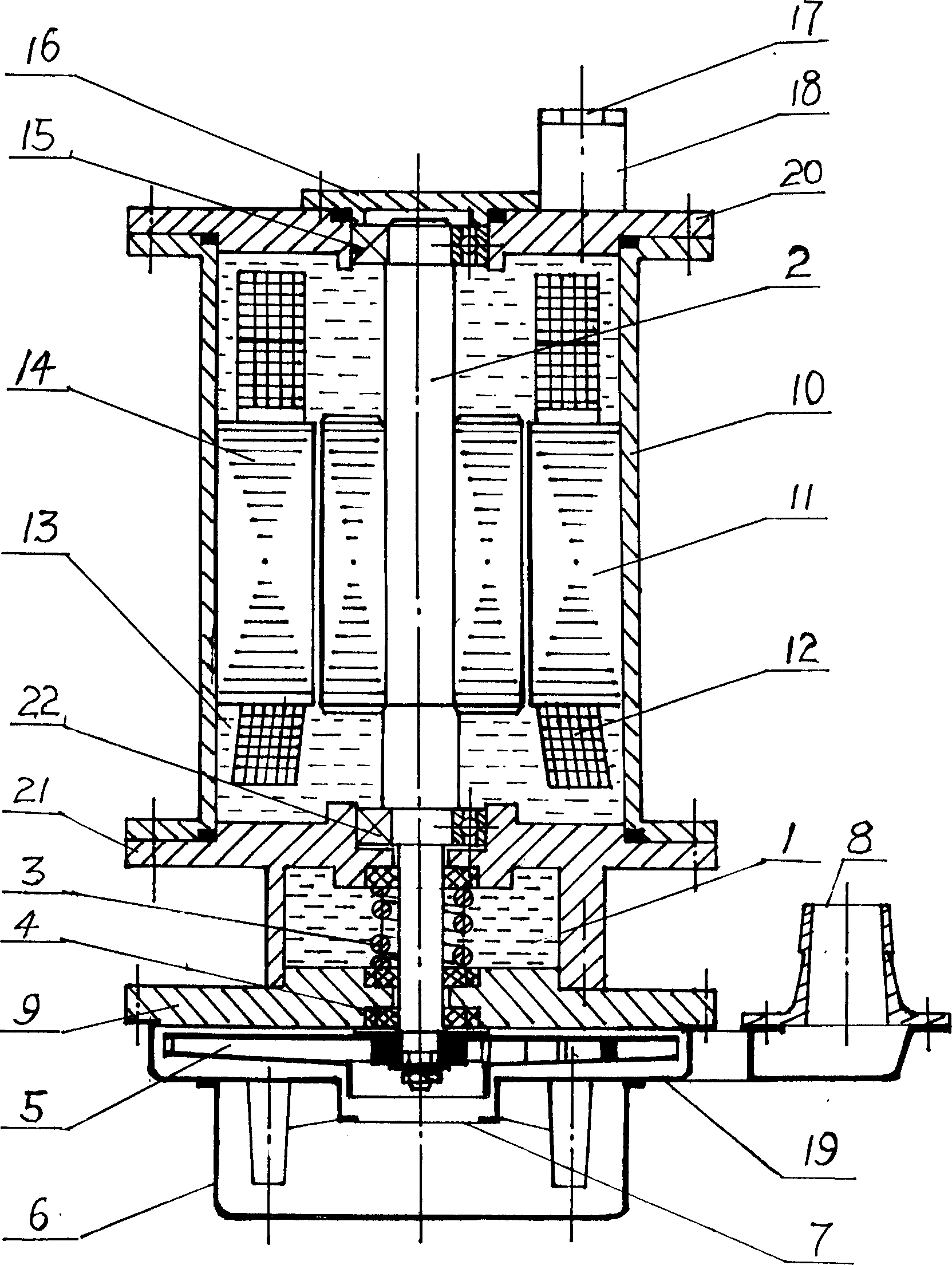

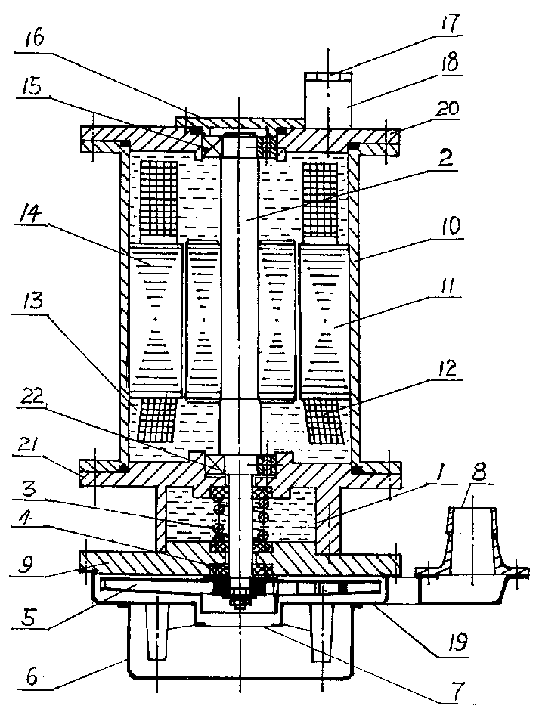

[0017] As shown in the figure: the submersible pump of oil-immersed waterproof line submersible motor, the rotor 14 and stator 11 of the submersible motor are located in the inner cavity 13 of the casing, the stator coil of the submersible motor is the waterproof line coil winding 12, and the stator and rotor of the submersible motor are located The cooling medium of the inner cavity 13 of the housing is insulating oil. The rear end of the motor shaft 2 is installed with a rear bearing 15 and a bearing cover 16 stuck in the center hole of the base 20. The base 20 is equipped with a lead-out tube 18, and the lead-out line 17 is connected by the lead-out line. The tube 18 leads out, the housing 10, the base 20 and the front cover 21 seal the inner chamber 13 of the housing; the middle part of the motor shaft 2 is installed with a front bearing 22 and a mechanical seal 3 which are stuck in the center hole of the front cover 21, and are mechanically sealed by the sealing chamber 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com