Herringbone gear with annular oil storage cavity

A technology of herringbone gears and oil storage chambers, applied to elements with teeth, belts/chains/gears, gear lubrication/cooling, etc., can solve the problem of affecting the strength and life of gears, destroying gear structures, and stress concentration in oil storage chambers and other issues to achieve the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

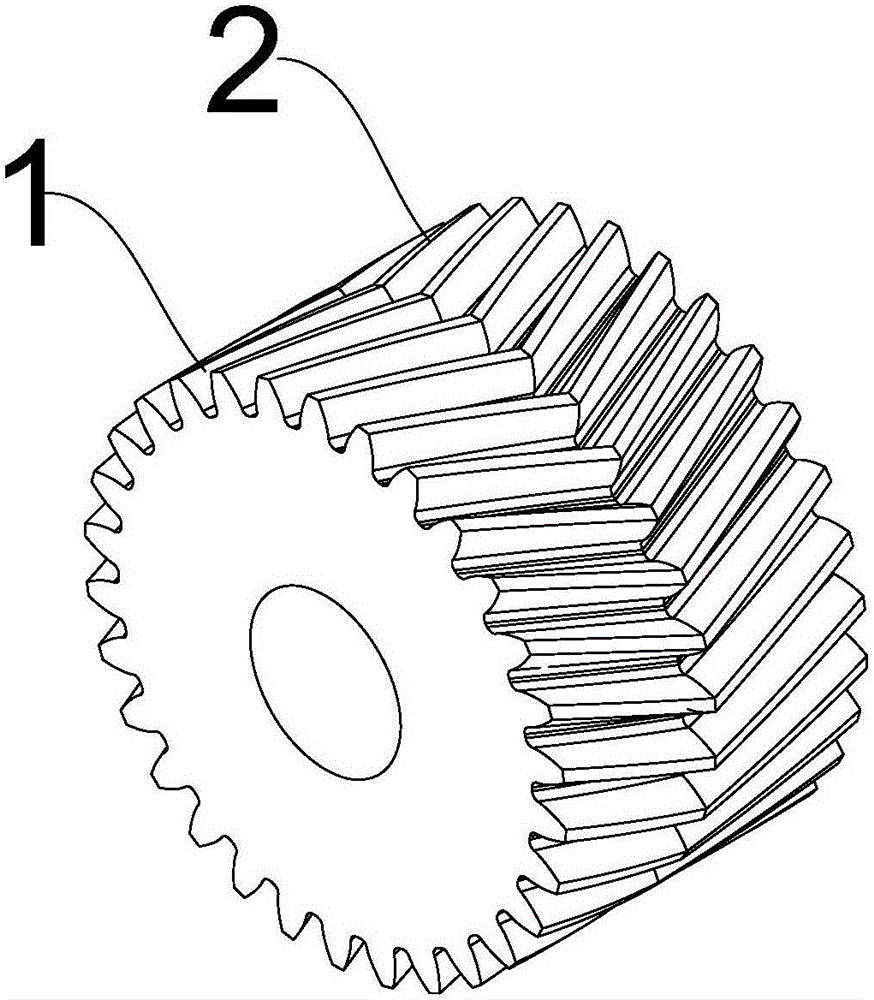

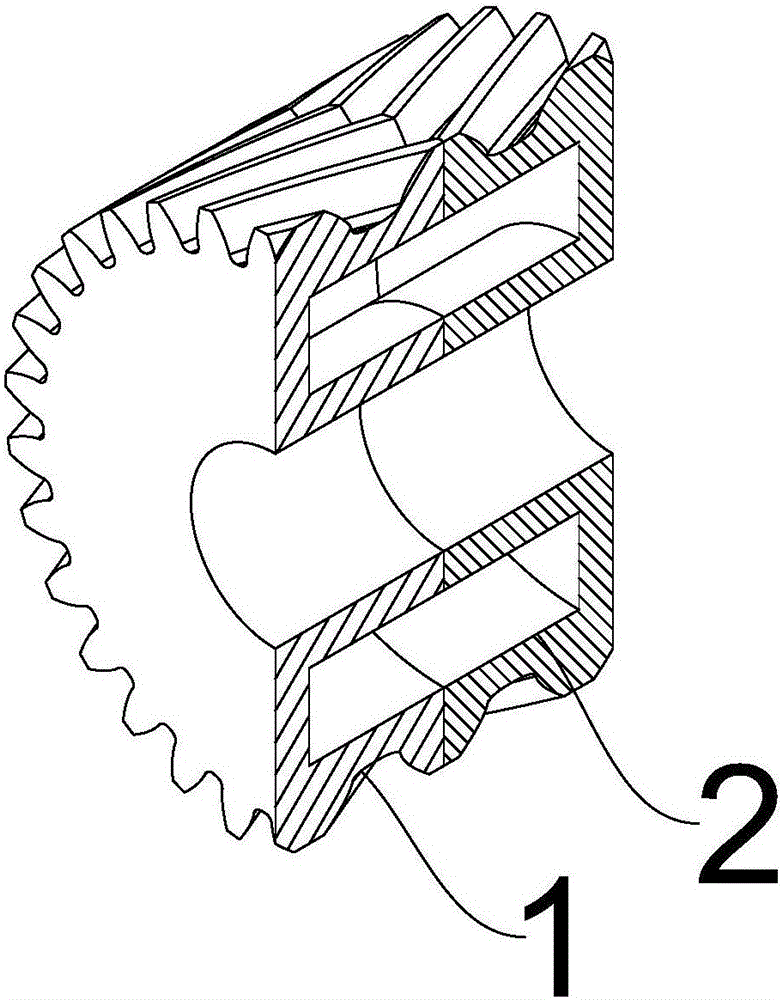

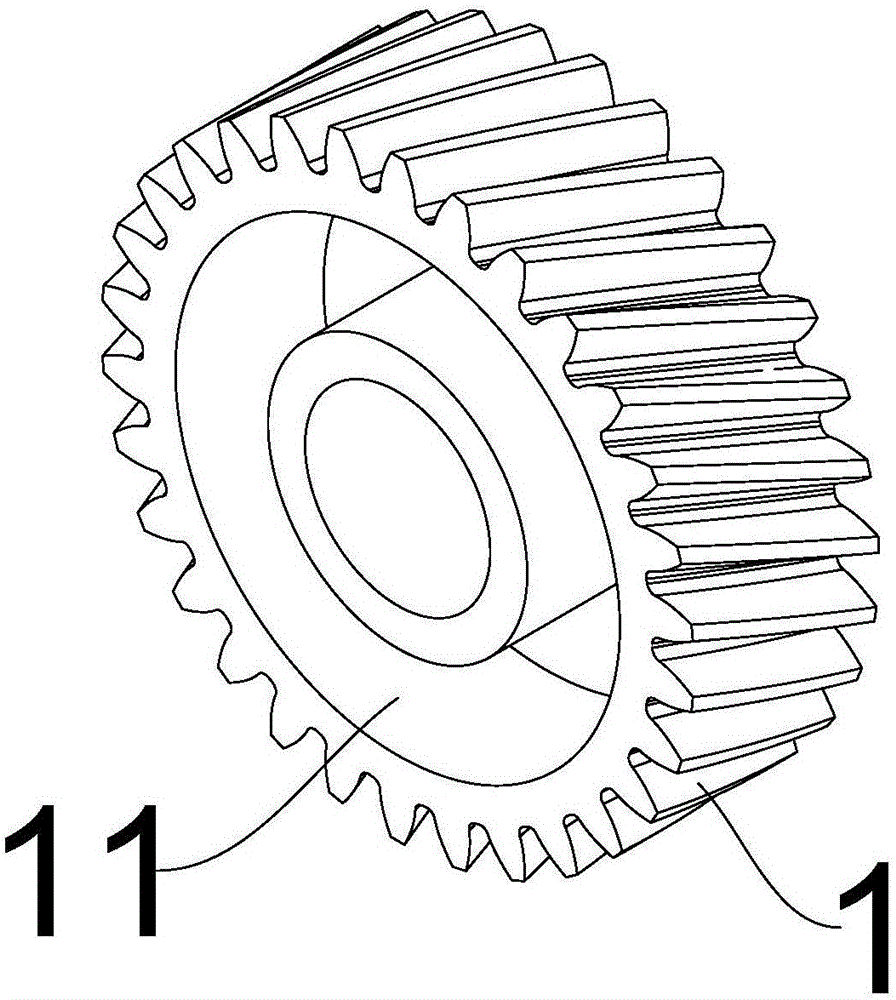

[0020] Such as figure 1 , figure 2 As shown, a herringbone gear with an annular oil storage chamber includes a left part 1 and a right part 2, the left part 1 and the right part 2 are mirror images of each other, as image 3 As shown, an annular groove 11 is provided on the fitting surface of the left part 1, and an annular groove 11 is also provided on the fitting surface of the right part 2 (not shown in the drawings), and the two annular grooves 11 are combined into one The annular oil storage chamber is filled with lubricating oil. When the herringbone gear with the annular oil storage chamber rotates, the lubricating oil in the annular oil storage chamber will flow to the periphery of the annular oil storage chamber under the action of centrifugal force. Since the direction of the axial force on the left part 1 and the right part 2 is opposite, as the herringbone gear with the annular oil storage chamber rotates, the gap between the left part 1 and the right part 2 wil...

Embodiment 2

[0022] On the basis of the first embodiment, the herringbone gear with an annular cavity further includes a gasket 3 arranged between the left part 1 and the right part 2 . In the first embodiment, the left part 1 and the right part 2 are directly connected, and there is only one joint, and the oil discharge speed is relatively slow. By adding the gasket 3, a joint can be added to increase the oil discharge speed. A plurality of spacers 3 can also be added to achieve a higher oil output speed. However, there are too many gaskets, and the lubricating oil pumped out between the gasket seams far from the left part 1 or the right part 2 cannot reach the surface of the gear teeth smoothly and cannot achieve the corresponding lubricating effect, so It is recommended that the number of spacers 3 does not exceed five.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com