Hard and tough anti-friction protection coating on surface of base body and preparation method of coating

A technology of protective coating and substrate, which is applied in the field of hard and tough anti-friction protective coating and its preparation on the surface of the substrate, which can solve the problems of adhesive wear, high friction coefficient of coating, difficult processing of alloy materials, etc., and prolong the service life , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

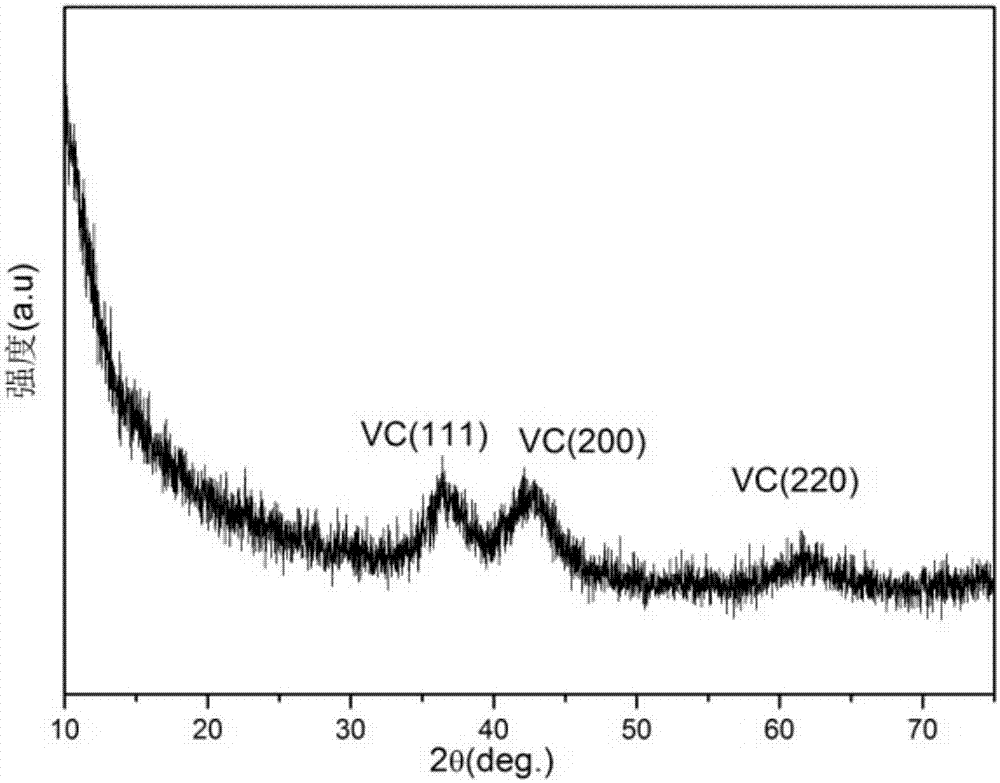

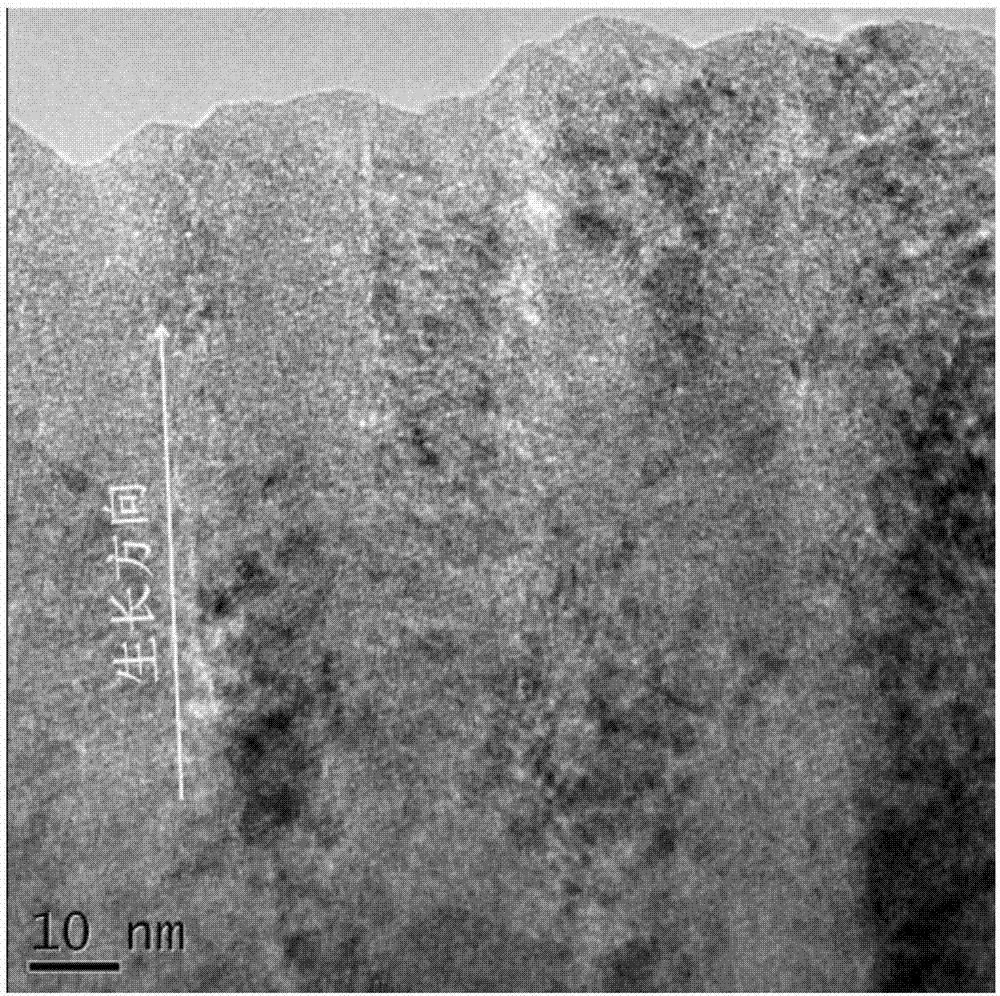

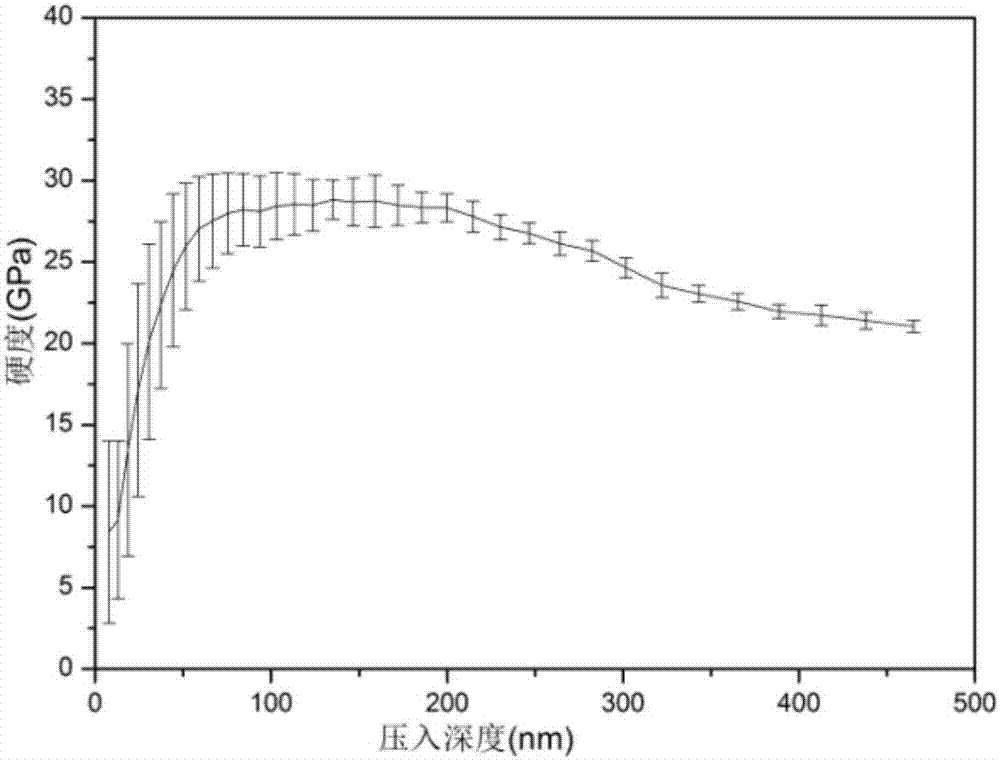

[0030] In this embodiment, the substrate is a cemented carbide blade, and the protective coating on the surface of the substrate is composed of V, Al, and C elements. Al atoms are solid-dissolved in the VC lattice, mainly forming nano-columnar crystal VAlC with a face-centered cubic structure. Wherein the V content is 40%, the Al content is 20%, the C content is 40%, and the diameter of the nanocrystal is 20nm.

[0031] The preparation method of this protective coating is as follows:

[0032] (1) After the substrate is ultrasonically cleaned with alcohol and acetone, it is dried, placed in the coating chamber of the compound ion beam thin film deposition equipment, and pre-evacuated to 2.0×10 -3 Pa.

[0033] (2) Introduce argon gas into the coating chamber, keep the argon gas pressure at 0.35Pa, apply a bias voltage of -150V on the substrate, turn on the anode layer ion source, and use the ionized argon ions to etch the surface of the substrate , the etching time is 30 minut...

Embodiment 2

[0041] In this embodiment, the substrate is a high-speed steel blade, and the protective coating on the surface of the substrate is composed of V, Al, and C elements. Al atoms are solid-dissolved in the VC lattice, mainly forming nano-columnar crystal VAlC with a face-centered cubic structure, wherein The V content is 30%, the Al content is 15%, the C content is 55%, and the diameter of the nanocrystal is controlled to be 10nm.

[0042] The preparation method of this protective coating is as follows:

[0043] (1) the same as the step (1) of the preparation method described in Example 1;

[0044] (2) the same as the step (2) of the preparation method described in Example 1;

[0045] (3) the same as the step (3) of the preparation method described in Example 1;

[0046] (4) Introduce argon and CH into the coating chamber 4 , keeping the partial pressure of argon at 0.9Pa, CH 4 The partial pressure is 0.15Pa, and the cathode magnetron source is V 2 AlC composite target, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com