Centrifugal pump with self-lubricating bearing and self-centering function

A self-lubricating bearing and centrifugal pump technology, which is applied to the parts, pumps, and pump components of the pumping device for elastic fluids, which can solve the problem of time-consuming and laborious assembly, disassembly and maintenance, time-consuming assembly personnel, and affecting the production efficiency of manufacturers and users. problems, to achieve the effect of avoiding secondary pollution, simple structure, and avoiding structural interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

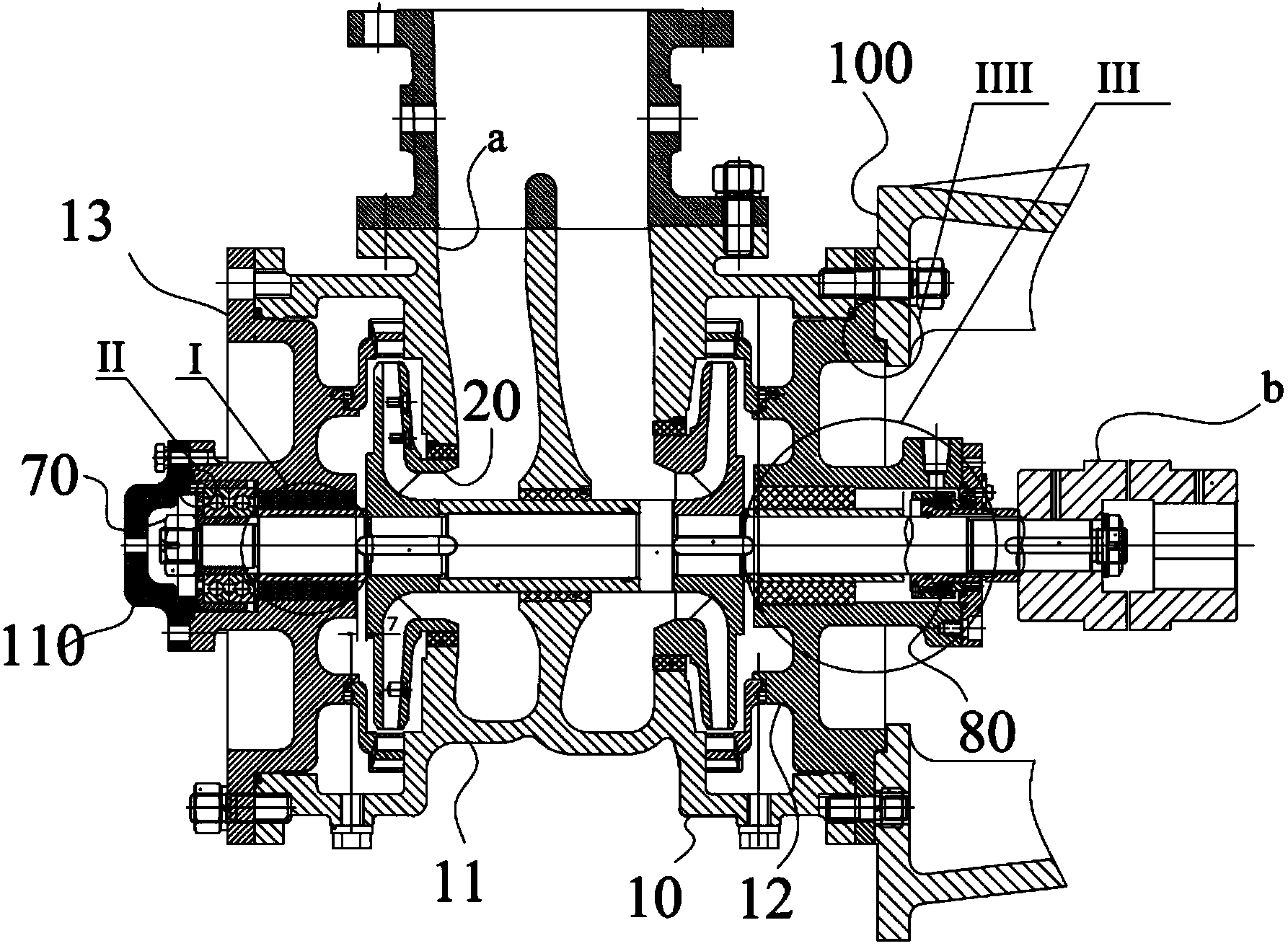

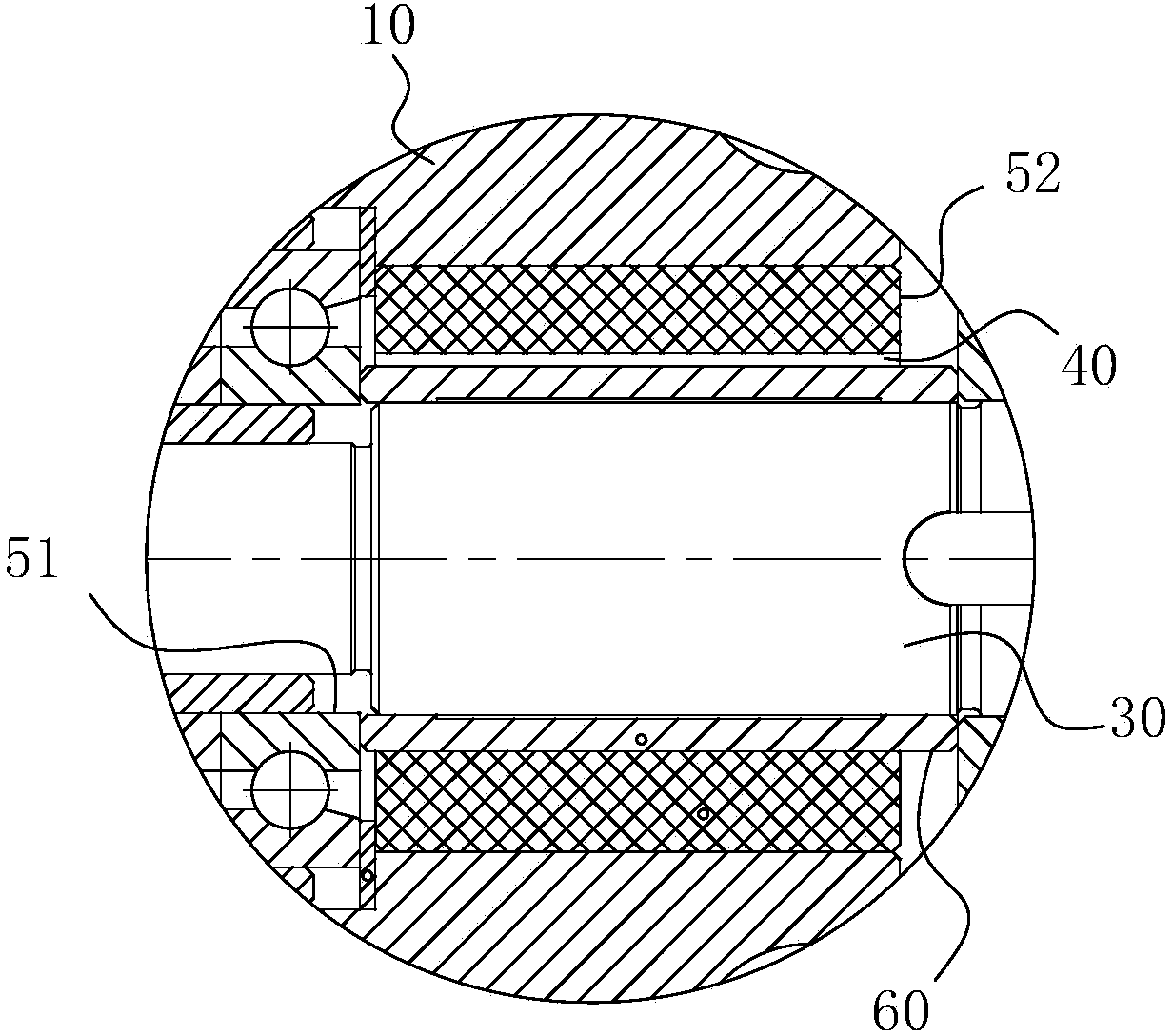

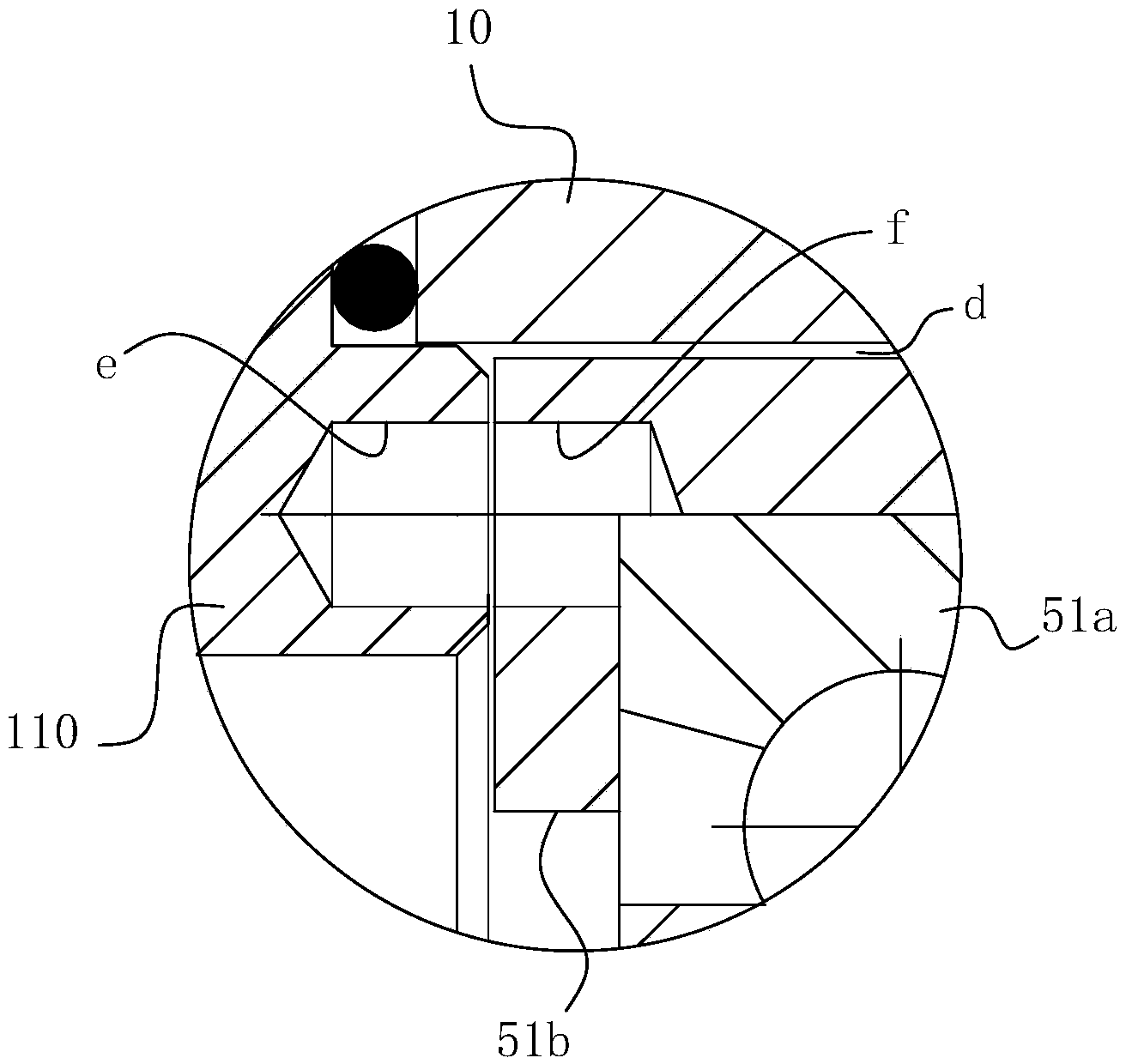

[0029] For ease of understanding, combined here Figure 1-5 Concrete components and workflow of the present invention are described as follows:

[0030] Centrifugal pumps under actual working conditions, such as Figure 1-5As shown, it is mainly assembled from the following components: the main base is composed of the pump body 11, and the pump chamber a is arranged in the pump body 11, and the pump shaft 30 is arranged through the pump chamber a, and the pump shaft 30 is from its right end to its left end Coupling b, connecting frame 100, mechanical seal assembly 80, drive end pump cover 12, auxiliary sliding bearing 53, secondary composite impeller and first stage composite impeller for forming pump impeller 20, non-drive end pump cover 13 are arranged accordingly , sliding bearing 52, rolling bearing 51, lock nut 70 and gland 110, the above components are assembled in sequence to form the whole centrifugal pump component. The pump body 11, the pump cover 12 at the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com