Hydrophilic lubricant auxiliary agent masterbatch and preparation method thereof, and hydrophilic self-lubricating polymer material including the same

A technology of polymer materials and hydrophilic polymers, applied in the field of medical polymer materials, can solve the problems of low coating adhesion, easy peeling off, economy, and high time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

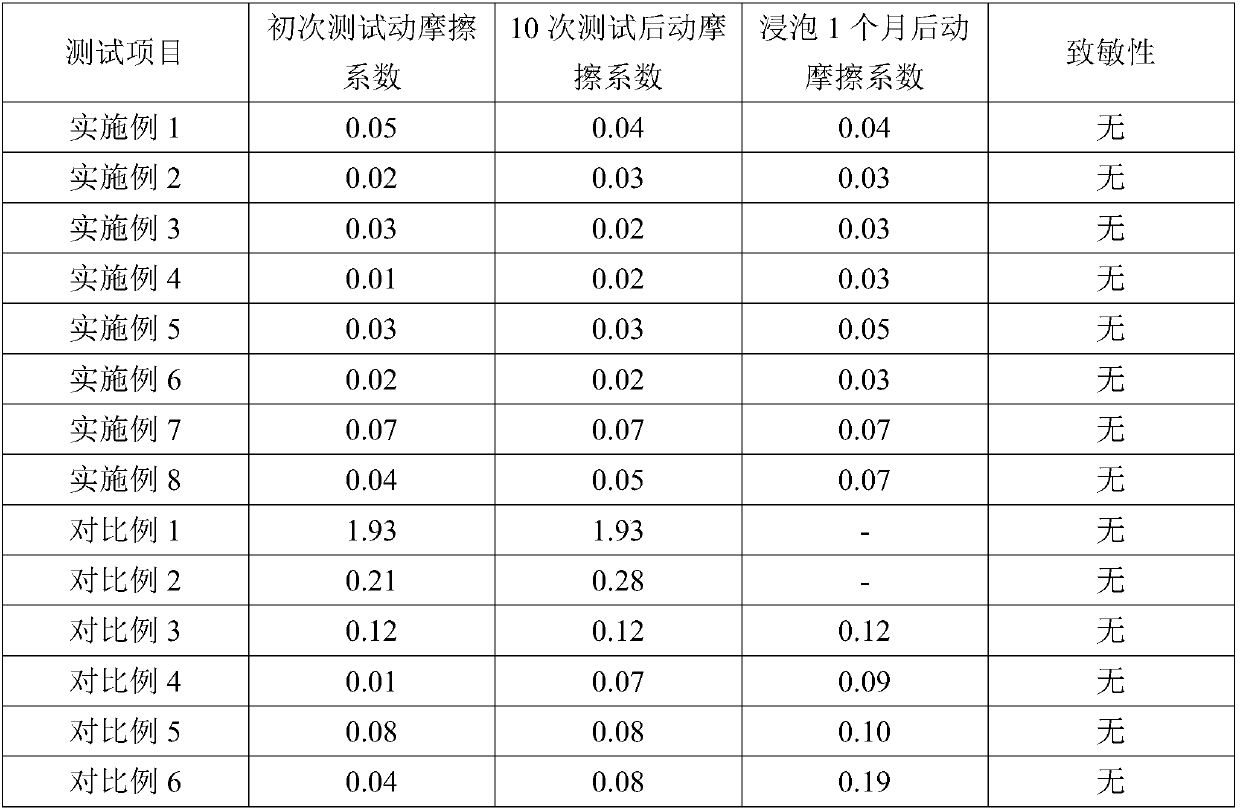

Examples

Embodiment 1

[0083] This embodiment provides a hydrophilic self-lubricating aid masterbatch and a hydrophilic self-lubricating polymer material, the preparation method of which is as follows:

[0084] Preparation of hydrophilic self-lubricating additive masterbatch:

[0085] (1) 3 parts by weight of polyethylene glycol and 17 parts by weight of polypropylene are added in the high mixer, and mixed for 10 minutes at a rotating speed of 300r / min to form a premix;

[0086] (2) The premix that step (1) obtains is added from the rear section feeding device of twin-screw extruder, and 80 parts by weight of amphiphilic oligomer with formula II structure is obtained from the front section of twin-screw extruder Add it to the feeding device, control the barrel temperature of the twin-screw extruder from the feeding section to the die direction from 130°C to 200°C, and the screw speed is 200r / min. After blending and extrusion, hydrophilic lubrication aids are obtained. agent masterbatch.

[0087] P...

Embodiment 2

[0091] This embodiment provides a hydrophilic self-lubricating aid masterbatch and a hydrophilic self-lubricating polymer material, the preparation method of which is as follows:

[0092] Preparation of hydrophilic self-lubricating additive masterbatch:

[0093] (1) 5 parts by weight of polyethylene glycol and 15 parts by weight of nylon 12 are added in the high mixer, and mixed for 10 minutes at a speed of 400r / min to form a premix;

[0094] (2) The premix that step (1) obtains is added from the rear section feeding device of twin-screw extruder, and 80 parts by weight of amphiphilic oligomer with formula III structure is obtained from the front section of twin-screw extruder Add it to the feeding device, control the temperature of the barrel of the twin-screw extruder from the feeding section to the die direction to increase from 150°C to 300°C, and the screw speed is 200r / min. After blending and extrusion, hydrophilic lubrication aids agent masterbatch.

[0095] Preparati...

Embodiment 3

[0099] This embodiment provides a hydrophilic self-lubricating aid masterbatch and a hydrophilic self-lubricating polymer material, the preparation method of which is as follows:

[0100] Preparation of hydrophilic self-lubricating additive masterbatch:

[0101] (1) Add 2 parts by weight of polyoxyethylene and 18 parts by weight of SEBS into the high mixer, and mix for 10 minutes at a rotating speed of 300r / min to form a premix;

[0102] (2) The premix that step (1) obtains is added from the rear section feeding device of twin-screw extruder, and 80 parts by weight of amphiphilic oligomer with formula IV structure is obtained from the front section of twin-screw extruder Add it to the feeding device, control the barrel temperature of the twin-screw extruder from the feeding section to the die direction from 130°C to 200°C, and the screw speed is 200r / min. After blending and extrusion, hydrophilic lubrication aids are obtained. agent masterbatch.

[0103] Preparation of hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com