Self-lubricating bearing and preparation method thereof

A technology of self-lubricating bearings and self-lubricating coatings, which is applied in the field of bearing manufacturing to achieve high hardness and self-lubricating properties, good toughness, and the effect of improving bearing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

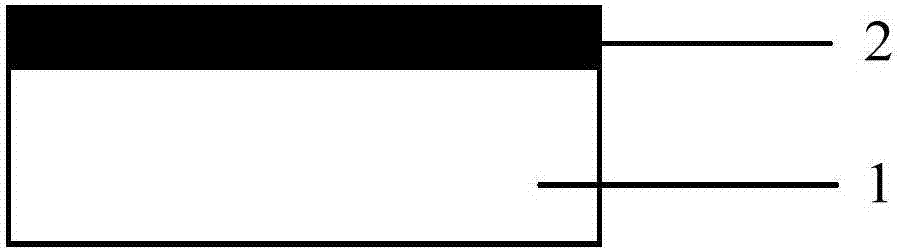

[0023] A self-lubricating bearing such as figure 1 As shown, the base material 1 is GCr15 bearing steel, the working surface of the bearing is graphene / calcium fluoride / ceramic self-lubricating coating 2, the mixed raw material powder of graphene / calcium fluoride / ceramic self-lubricating coating, using CO 2 Laser coating technology uses synchronous powder feeding to clad on the surface of the base material, which is obtained from lubricated bearings.

[0024] The above-mentioned self-lubricating bearing is prepared through the following steps:

[0025] (1) Add alumina-coated graphene and alumina-coated calcium fluoride powder to nickel-coated alumina, nickel-coated silicon nitride, titanium carbide and nickel powder to configure a mixed powder, the mixed powder includes: 34% Nickel-coated alumina, 35% nickel-coated silicon nitride, 5% alumina-coated graphene, 5% alumina-coated calcium fluoride, 20% titanium carbide, 1% nickel, the sum of the weight percentages of each powder ...

Embodiment 2

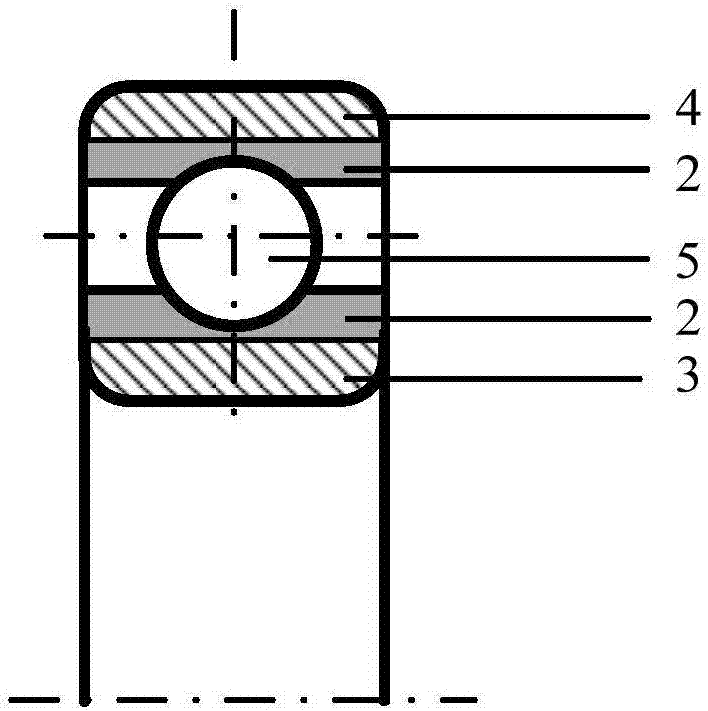

[0029] A self-lubricating bearing is a deep groove ball bearing, such as figure 2 As shown, the inner ring base 3 and the outer ring base 4 are GCr15SiMn alloy steel, the working surface of the bearing is graphene / calcium fluoride / ceramic self-lubricating coating 2, and the middle position is a ball 5. Mixed raw material powder of graphene / CaF2 / ceramic self-lubricating coating, utilizing CO 2 Laser coating technology uses synchronous powder feeding to clad on the surface of the base material, which is obtained from lubricated bearings.

[0030] The above-mentioned self-lubricating bearing is prepared through the following steps:

[0031] (1) adding alumina-coated graphene and alumina-coated calcium fluoride powder to nickel-coated alumina, nickel-coated silicon nitride, titanium carbide and nickel powder to configure a mixed powder, the mixed powder includes: 40% Nickel-coated alumina, 20% nickel-coated silicon nitride, 8% alumina-coated graphene, 6% alumina-coated calcium ...

Embodiment 3

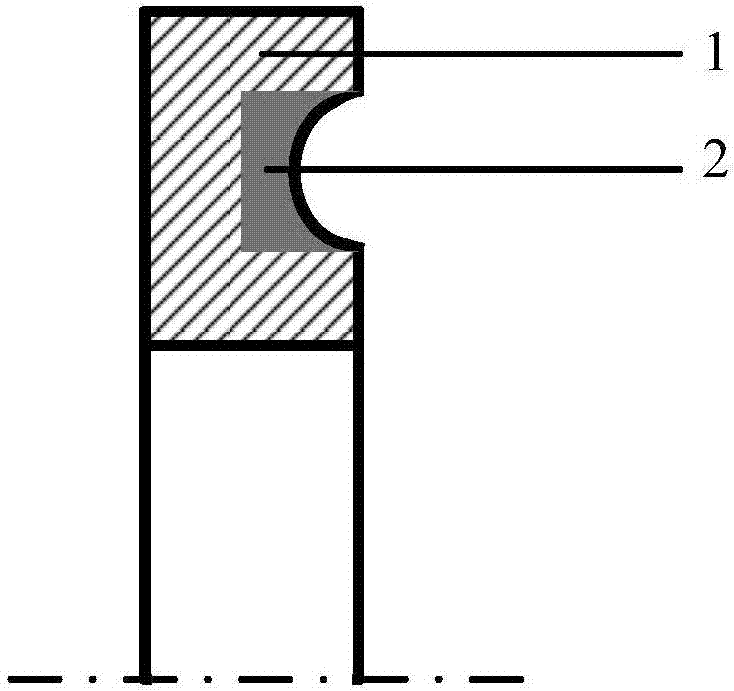

[0035] A self-lubricating bearing is a thrust ball bearing, such as image 3 As shown, the base material 1 is GCr15 bearing steel, and the working surface of the bearing is graphene / calcium fluoride / ceramic self-lubricating coating 2. Mixed raw material powder of graphene / CaF2 / ceramic self-lubricating coating, utilizing CO 2 Laser coating technology uses synchronous powder feeding to clad on the surface of the base material, which is obtained from lubricated bearings.

[0036] The above-mentioned self-lubricating bearing is prepared through the following steps:

[0037] (1) Adding alumina-coated graphene and alumina-coated calcium fluoride powder to nickel-coated alumina, nickel-coated silicon nitride, titanium carbide and nickel powder to configure a mixed powder, the mixed powder includes: 49.5% Nickel-coated alumina, 20% nickel-coated silicon nitride, 5% alumina-coated graphene, 5% alumina-coated calcium fluoride, 20% titanium carbide, 0.5% nickel, the sum of the weight p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com