A load-bearing plane conveying device

A conveying device and plane technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of inability to achieve plane load-bearing conveying, increase the friction of the conveyor belt, increase the load of the transmission motor, etc., so as to improve the practical value and improve the production. Efficiency, the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

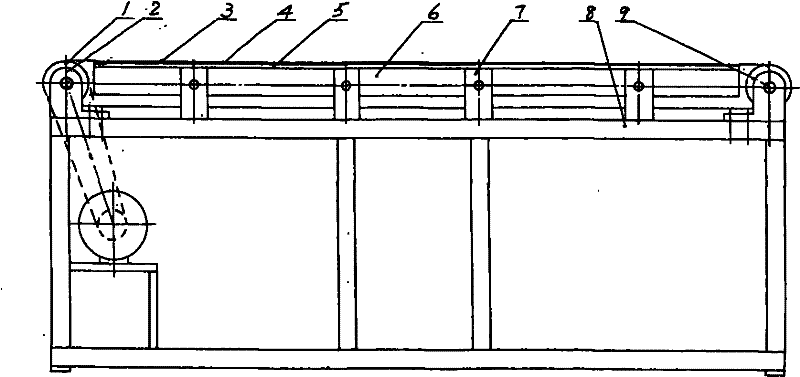

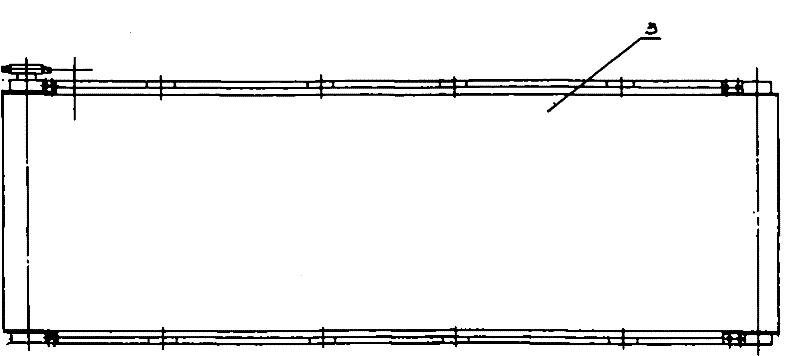

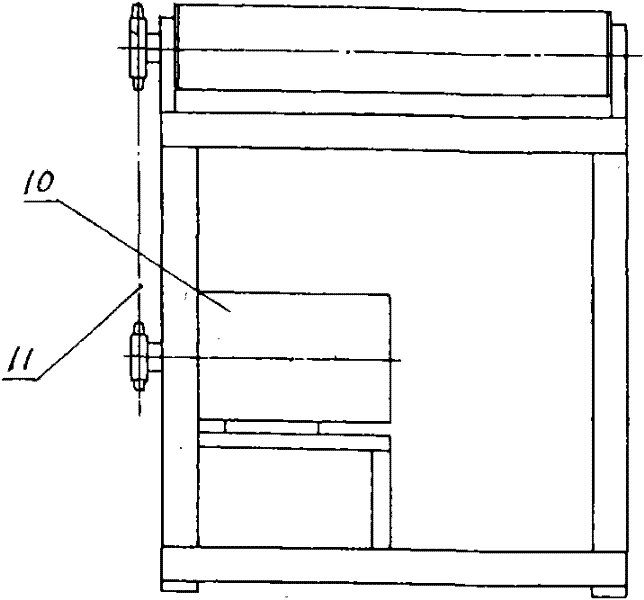

[0010] See attached figure 1 ~ attached Figure 4 Shown:

[0011] This embodiment is composed of driving roller 1, bearing seat 2, conveyor belt 3, graphite gasket 4, pallet 5, bracket 6, bracket 7, frame 8, driven roller 9, reduction motor 10, and transmission chain 11. The driving roller 1 is supported by the bearing seat 2 and installed on the left side of the frame 8, the driven roller 9 is supported by the bearing seat 2 and installed on the right side of the frame 8, and the geared motor installed in the middle of the left side of the frame 8 10 drives the driving roller 1 to rotate through the transmission chain 11, and the driven roller 9 rotates synchronously with the conveyor belt 3. The bracket 6 made of steel pipe is held flat, and the bracket 6 is installed on the frame 8 through the bracket 7, so that the bracket 6, the supporting plate 5, and the graphite gasket 4 are all installed inside the conveyor belt 3, so that the conveyor belt 3 can move in a plane an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com