Hollow elevator guide rail

A technology of elevator guide rails and guide rail seats, which is applied in sustainable buildings, elevators, transportation and packaging, etc., and can solve problems such as labor-intensive, troublesome, and elevator guide rails do not have self-lubricating functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

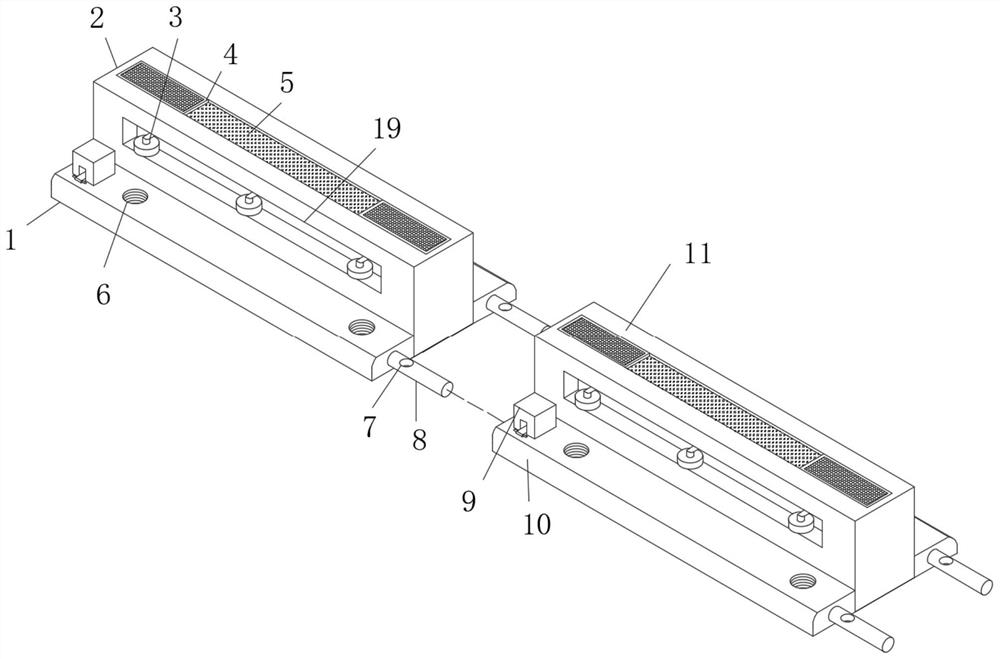

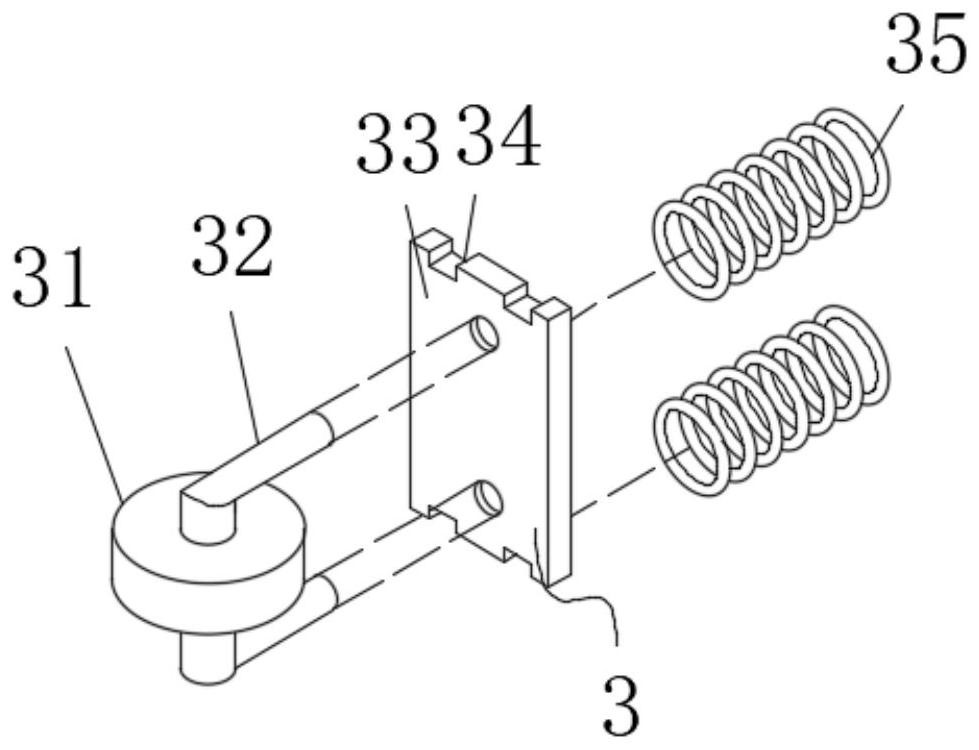

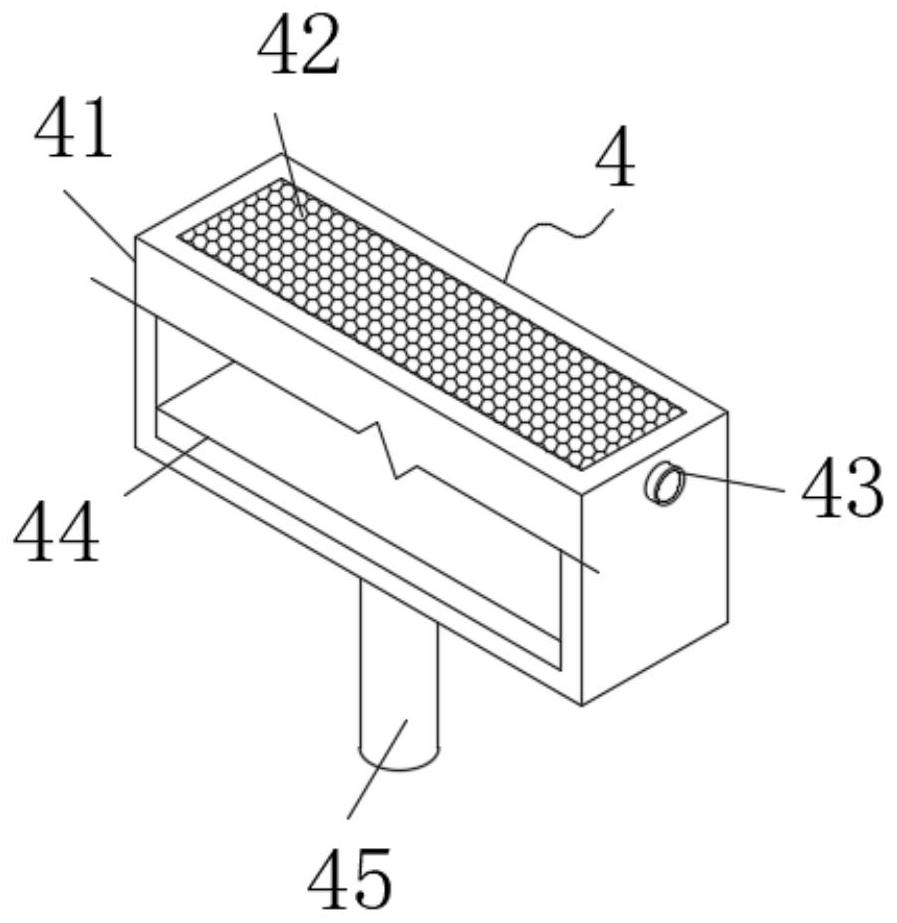

[0044] see Figure 1-7 , the present invention provides a technical solution: a hollow elevator guide rail, comprising a first combined guide rail body 2 and a second combined guide rail body 11, the bottoms of the first combined guide rail body 2 and the second combined guide rail body 11 are respectively The first guide rail seat 1 and the second guide rail seat 10 are fixedly installed, and the insides of the first guide rail seat 1 and the second guide rail seat 10 are provided with mounting screw holes 6, and the first guide rail seat 1 and the second guide rail seat 10 The side walls of 10 are fixedly installed with connection side shafts 8, and the inside of the connection side shafts 8 is provided with a limit card hole 7, and a connection assembly 9 is fixedly installed on the top surface of the second guide rail seat 10. The sidewalls of a combination guide rail main body 2 and the second combination guide rail main body 11 are provided with installation side grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com