Ship lock head side pier combined template and installation method

A technology of combining formwork and formwork, which is applied to ship locks, ship lifting devices, formwork/formwork components, etc., can solve the problem of increasing the dead weight of the formwork and the amount of steel used for the pier at the head of the lock, increasing the construction cost, and the difficulty of erecting the formwork by the construction personnel. and other problems, to achieve the effect of safe and efficient installation method, reduce self-weight, improve installation efficiency and installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and the combined formwork embodiment of the ship lock head side pier of Hangzhou Babao Ship Lock.

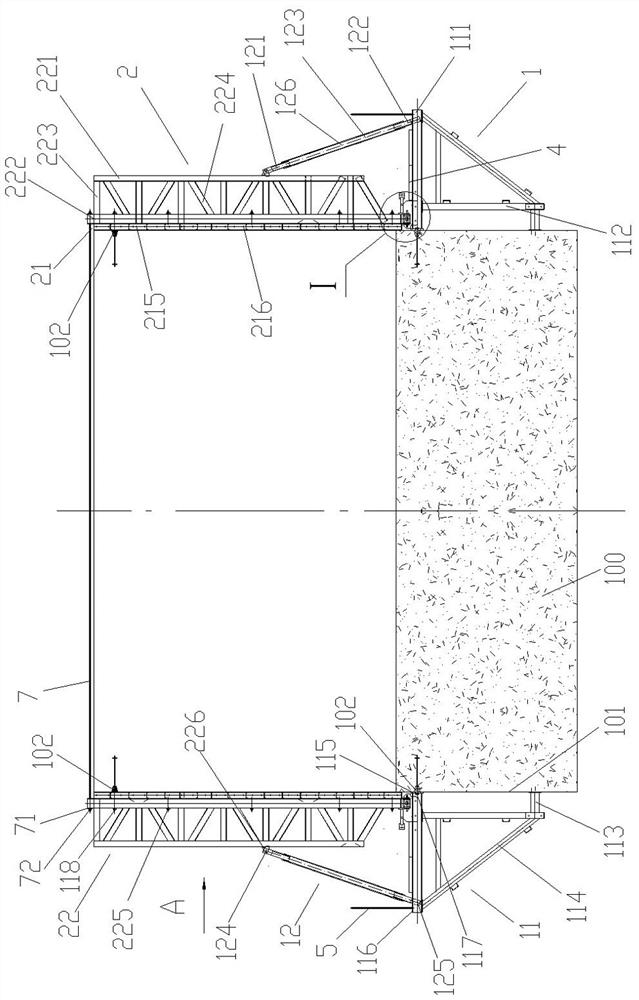

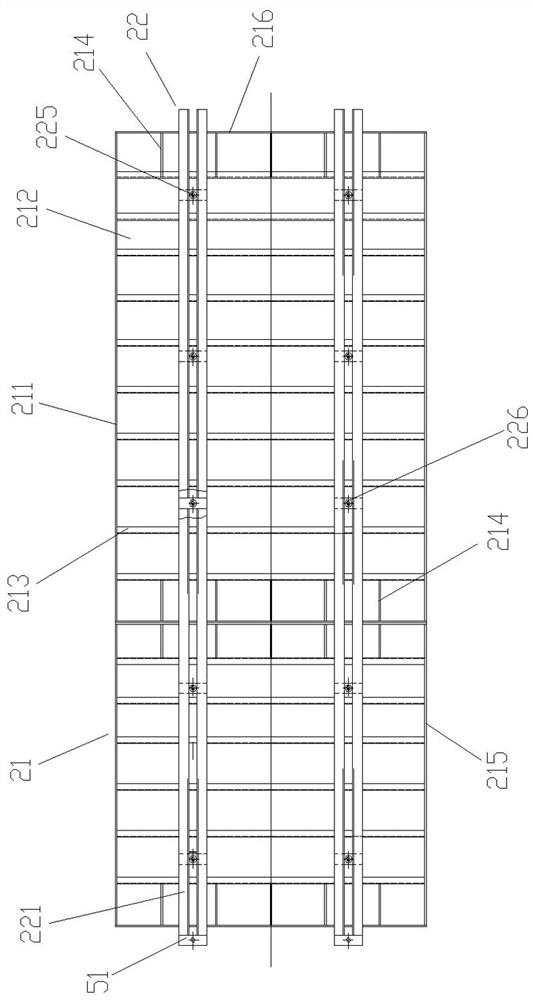

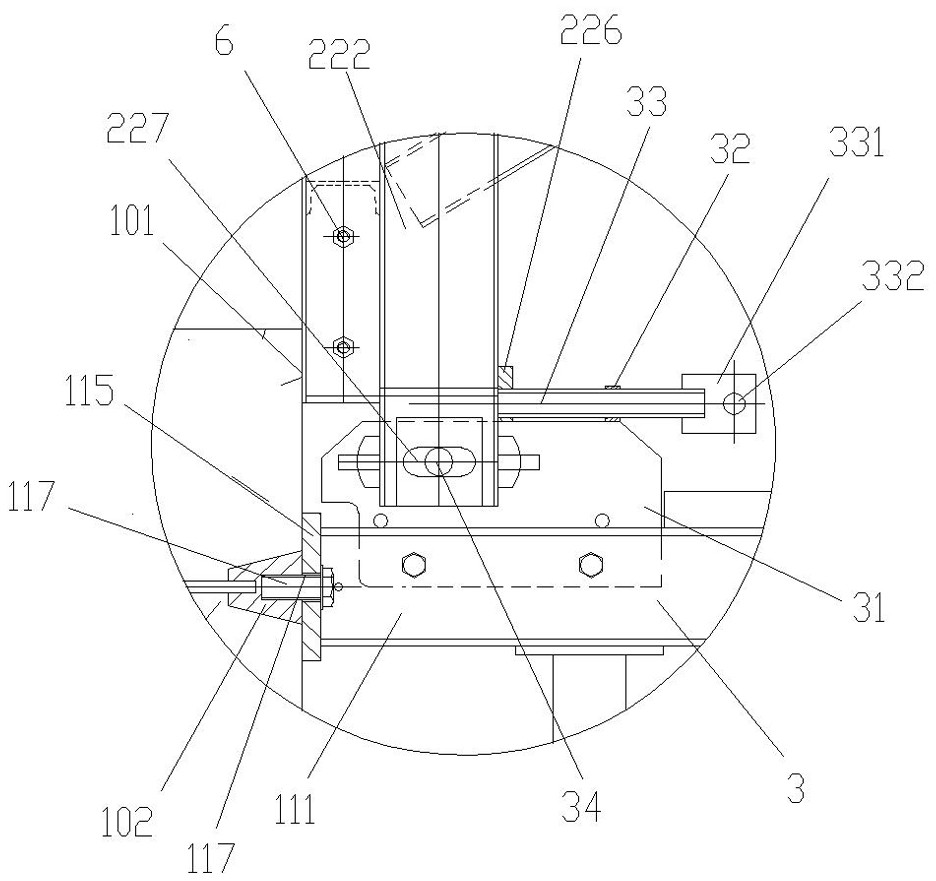

[0026] Such as figure 1 with figure 2 As shown, the present embodiment includes a cantilever hanger 1 and a truss formwork 2. The cantilever hanger 1 includes two parallel support tripods 11 and a pair of adjustable struts 12. The support tripod 11 includes a horizontal bar 111 and a vertical bar 112. , the lower cross bar 113 and the diagonal brace 114, one end of the horizontal bar 111 is vertically welded to the upper end of the vertical bar 112, and one end of the horizontal bar 111 is fixed on the pre-buried climbing anchor cone 102 in the upper part of the vertical side 101 of the poured concrete, vertical The lower end of the bar 112 is vertically welded to one end of the lower cross bar 113, and the other end of the lower cross bar 113 leans against the vertical side 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com