Self-propelled recyclable steel pipe pile and construction method

A construction method and technology of steel pipe piles, which are applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of inability to use cement reinforcement cage cast-in-place piles, underground pollution, waste of building materials, etc., and achieve easy recycling and reuse, saving Steel and cement, the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

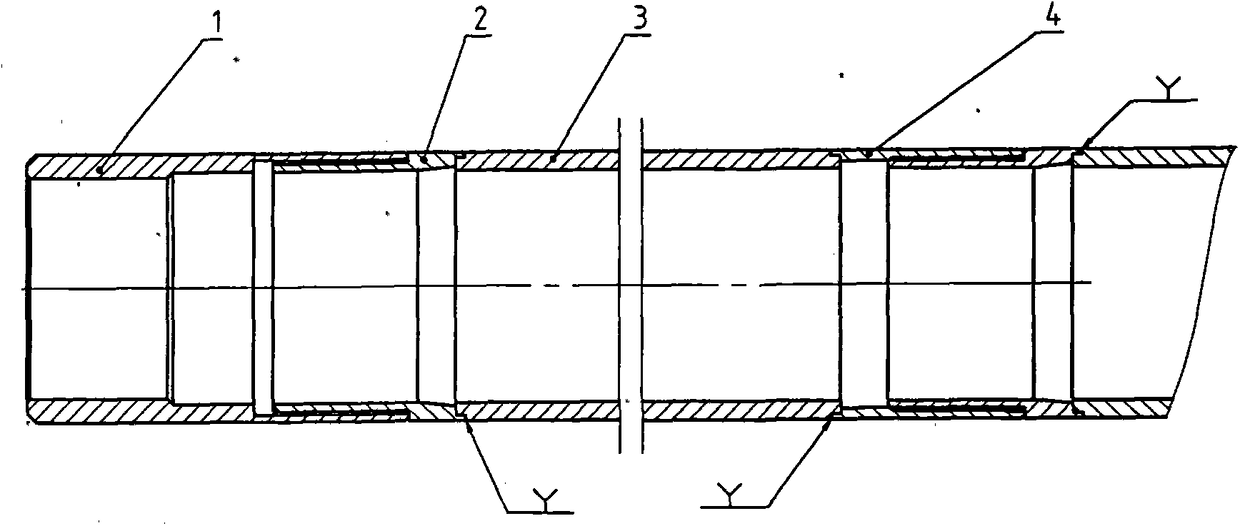

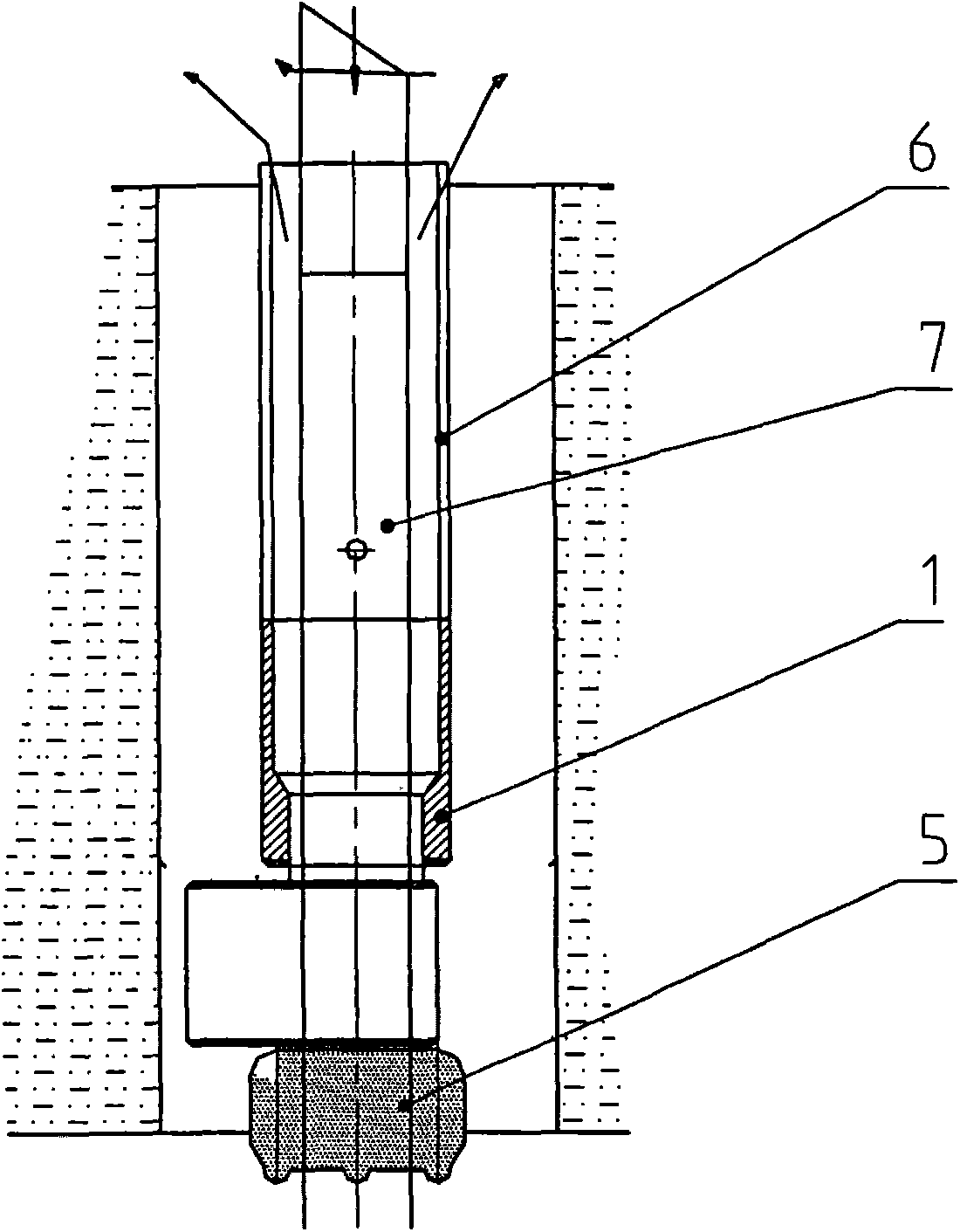

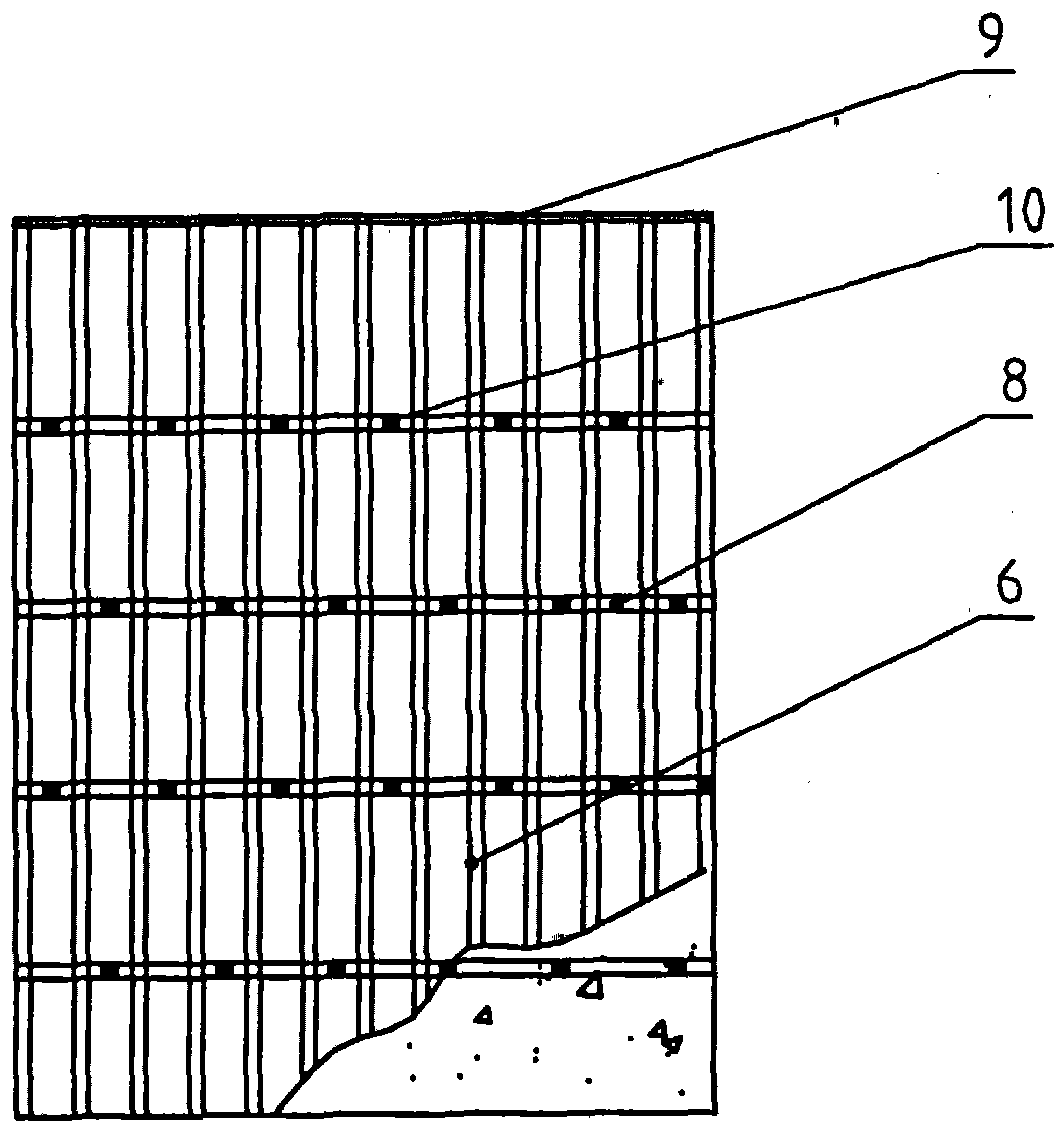

[0023] Refer to attached figure 1 to attach Figure 4 , in the figure: self-propelled connector 1, external threaded joint 2, steel pipe 3, internal threaded joint 4, eccentric drill bit 5, self-approaching recyclable steel pipe pile 6, impactor 7, waist beam 8, retrievable crown beam 9 , Anchor cable 10.

[0024] In this embodiment, the externally threaded joint 2 and the internally threaded joint 4 are fixed to the two ends of the steel pipe 3 through the joints, and then welded firmly with grooves to form a steel pipe pile; the self-advancing connector 1 and a steel pipe pile The external thread joint end connection; the steel pipe pile with a self-advancing connector is the starting end, through the internal and external thread joints, each section of steel pipe piles is connected in pairs, refer to the attached figure 1 .

[0025] In this embodiment, the eccentric drill bit 5 is connected to the self-propelled connector 1, and the impactor 7 is connected to the eccentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com