Installation technology for universal mooring equipment of three-stand-column floating type wind power platform

A mooring equipment and installation process technology, applied in wind power generation, ships and other directions, can solve problems such as difficulty in ensuring concentricity, large anchor chain wear, structural overload, etc., to improve construction efficiency, reduce construction costs, reduce wear and structure. The effect of overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

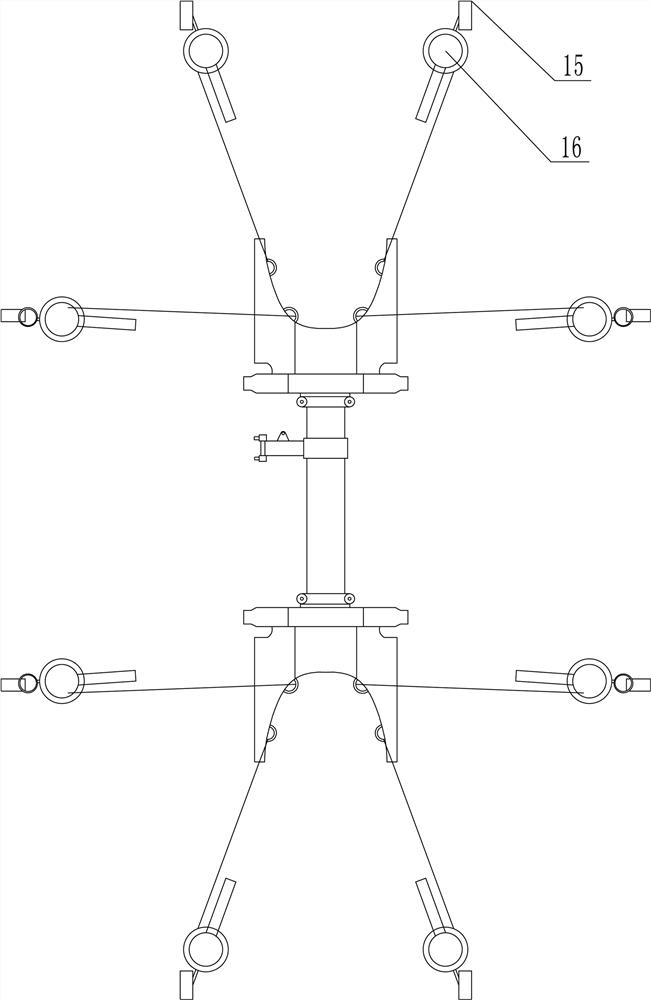

[0044] Such as Figure 1~Figure 12 As shown, the installation process of the universal mooring equipment of the three-column floating wind power platform includes the following steps:

[0045] S1, install multiple eye plates 15 and lifting devices on the floating wind power platform; the lifting device is preferably a chain hoist 16; the preferred number of eye plates 15 is 8, and the 8 eye plates 15 are symmetrically distributed around the chain stopper to be assembled ;

[0046] When in use, first connect the dummy shaft tooling with the hand chain hoist 16 connected to the eye plate 15, and then adjust 8 groups of hand chain hoists 16 to cooperate with the level device to tighten the tooling to the predetermined installation position to achieve pre-fixation; and then carry out welding work;

[0047] S2. Assemble the positioning tool consisting of the bracket and the dummy shaft on the horizontal plane, and install the assembled tool on the side surface of the floating win...

Embodiment 2

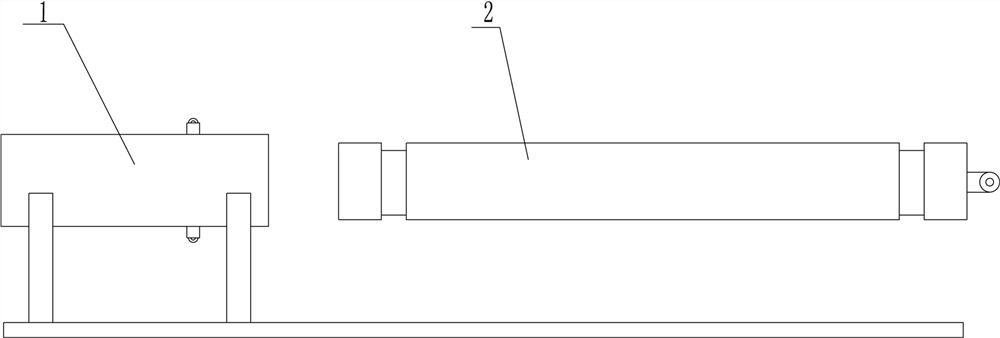

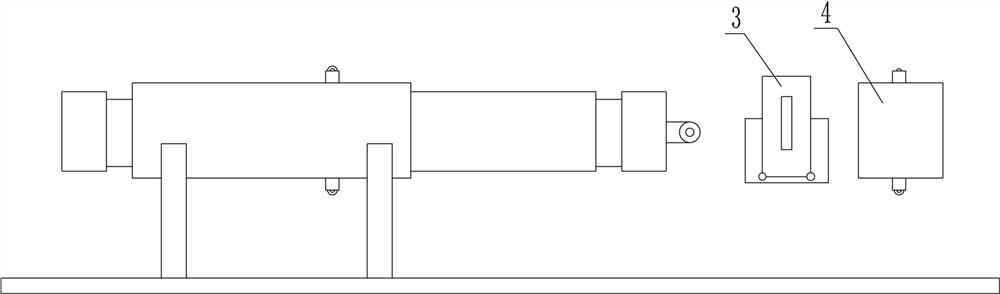

[0071] The structure of the above-mentioned dummy shaft is as follows: it includes the dummy shaft 2, and one end of the dummy shaft 2 is connected with a pull ring; Ring-shaped threaded holes are provided; shaft gaskets are sheathed on the outer surface of the dummy shaft, and the shaft gaskets are in contact with the mounting surface; both ends of the dummy shaft are connected to the brackets.

[0072] Preferably, the shaft gasket includes an upper section 4 of the shaft gasket and a lower section 1 of the shaft gasket; a second collar 5 is connected between the upper section 4 of the shaft gasket and the lower section 1 of the shaft gasket.

[0073] Preferably, washers 6 and bushings 7 are sleeved at both ends of the dummy shaft 2 .

[0074] Preferably, the installation surface includes a horizontal plate, a plurality of vertical support plates are connected to the upper surface of the horizontal plate, and an arc-shaped groove is provided on the top of the support plate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com