Process for solvent extraction separation purification of rare earth element

A rare earth element and process technology, applied in the field of solvent extraction, separation and purification of rare earth elements, can solve the problems of high acid and alkali consumption, ammonia nitrogen wastewater pollution, etc., and achieve the effects of less acid and alkali consumption, easy stripping, simple and flexible process

Active Publication Date: 2010-11-10

GRIREM ADVANCED MATERIALS CO LTD

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a kind of process method of extracting, separating and purifying rare earth elements from mixed sulfuric acid rare earth solution, and this process method focuses on solving the above-mentioned ammonium bicarbonate transformation or P204 extraction transformation process to have high acid-base consumption, and ammonia nitrogen wastewater to water resources. Pollution and other issues, thereby simplifying the process flow, reducing chemical material consumption and operating costs, and eliminating ammonia nitrogen wastewater pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

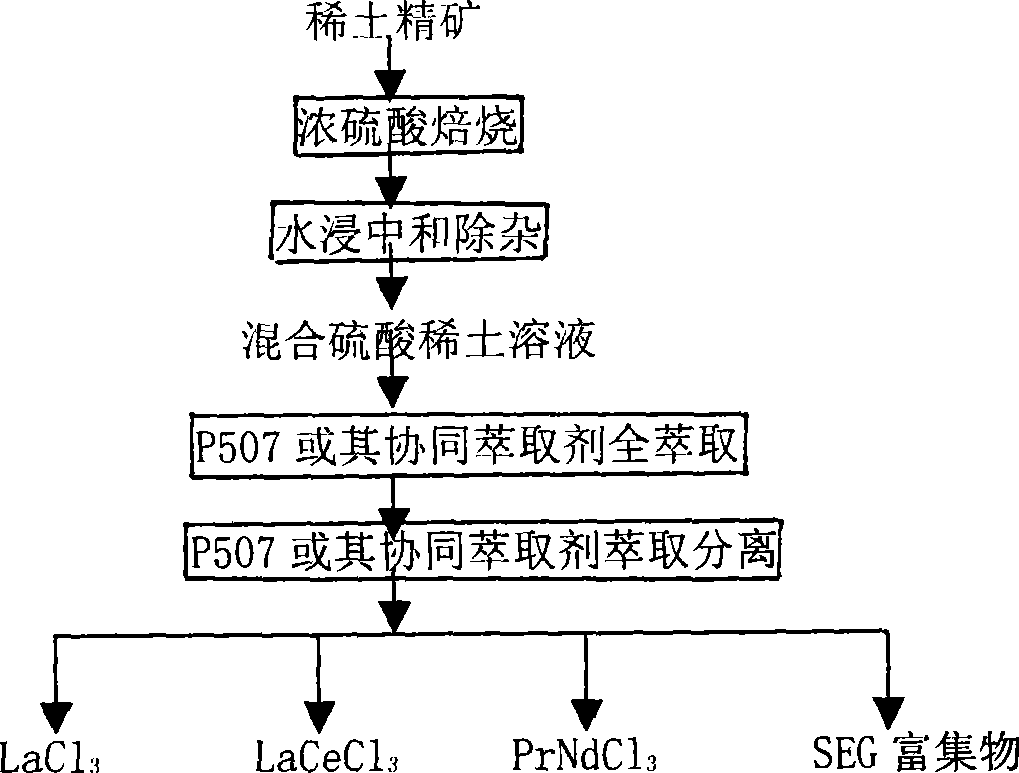

Login to View More Abstract

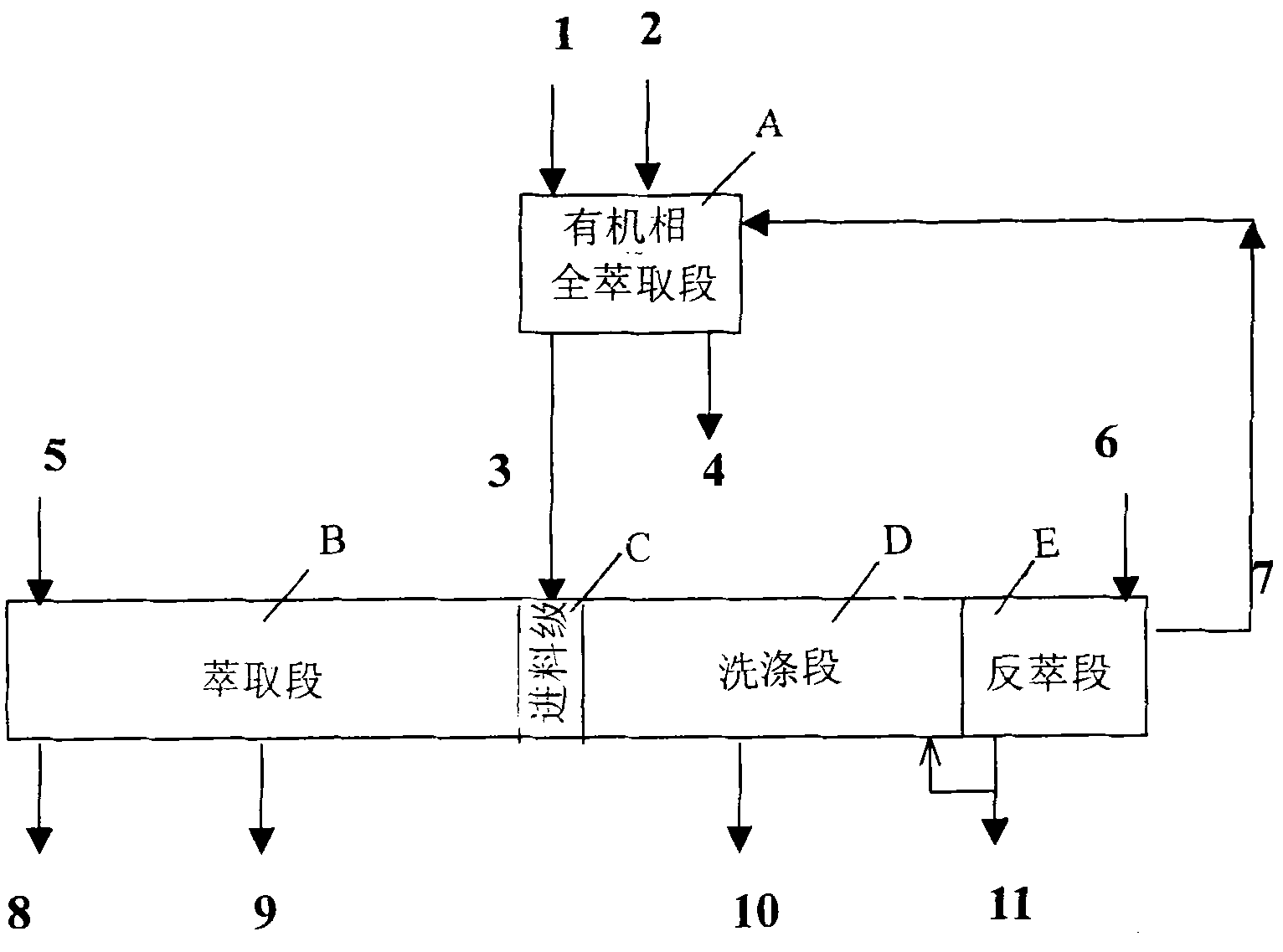

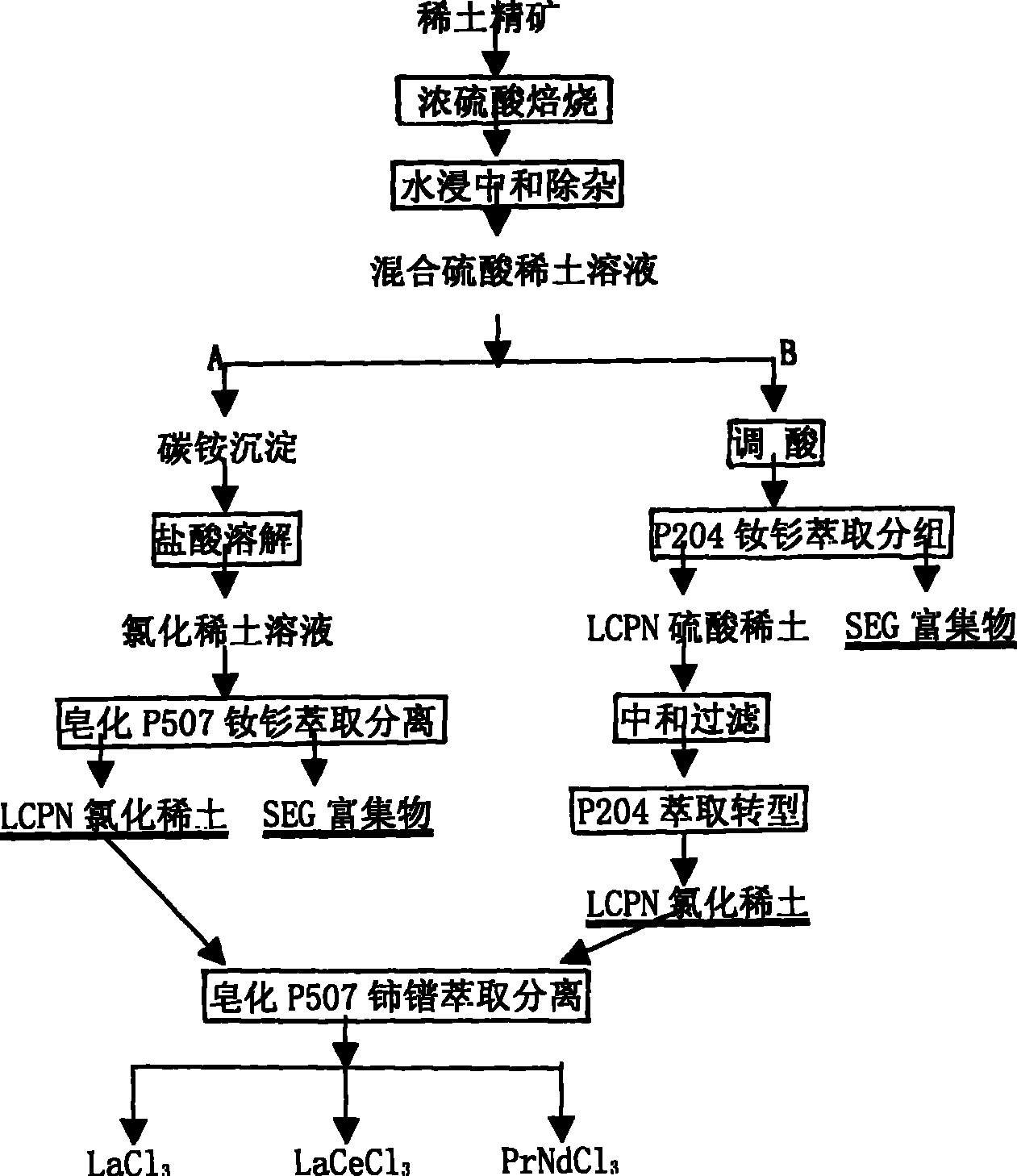

The invention provides a process method for separating and purifying rare earth elements by solvent extraction. The method takes a mixed rare earth sulfate solution obtained from a rare earth ore treated by sulphuric acid as a raw material, directly adopts a nonsaponifiable P507 extraction agent or a synergistic extraction agent containing the P507 to completely extract rare earth in a material liquid into an organic phase, and then takes the organic phase as a rare earth material liquid to extract, separate and purify the rare earth or directly backextract to produce mixed chlorinated rare earth or rare earth nitrate. The process method is simple and flexible, does not saponify the organic phase during the extraction and separation process, does not produce ammonia nitrogen waste water, is easy to backextract middle and heavy rare earths, and has less consumption of acid and base and low production cost.

Description

Solvent extraction process for separating and purifying rare earth elements technical field The invention relates to a process method for solvent extraction, separation and purification of rare earth elements. Specifically, the mixed rare earth sulfate solution obtained by sulfuric acid decomposition of rare earth ore is used as raw material, and non-saponified P507 (HEH / EHP, 2-ethylhexylphosphonic acid mono-2-ethylhexyl ester) or synergistic extraction containing P507 is directly used The rare earth in the feed liquid is fully extracted into the organic phase, and then the organic phase is used as the rare earth feed liquid for rare earth extraction and separation or direct back extraction to produce mixed rare earth chloride or rare earth nitrate. Background technique Rare earth is composed of 15 lanthanide elements (lanthanum La cerium Ce promethium Pm praseodymium Pr neodymium Nd samarium Sm europium Eu gadolinium Gd terbium Tb dysprosium Dy holmium Ho Er Er Thulium Tm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22B3/26C22B3/08C22B59/00

CPCY02P10/20

Inventor 黄小卫龙志奇李红卫彭新林刘营张永奇李建宁赵娜

Owner GRIREM ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com