Method for extracting iron and vanadium from vanadium-titanium magnetite concentrates

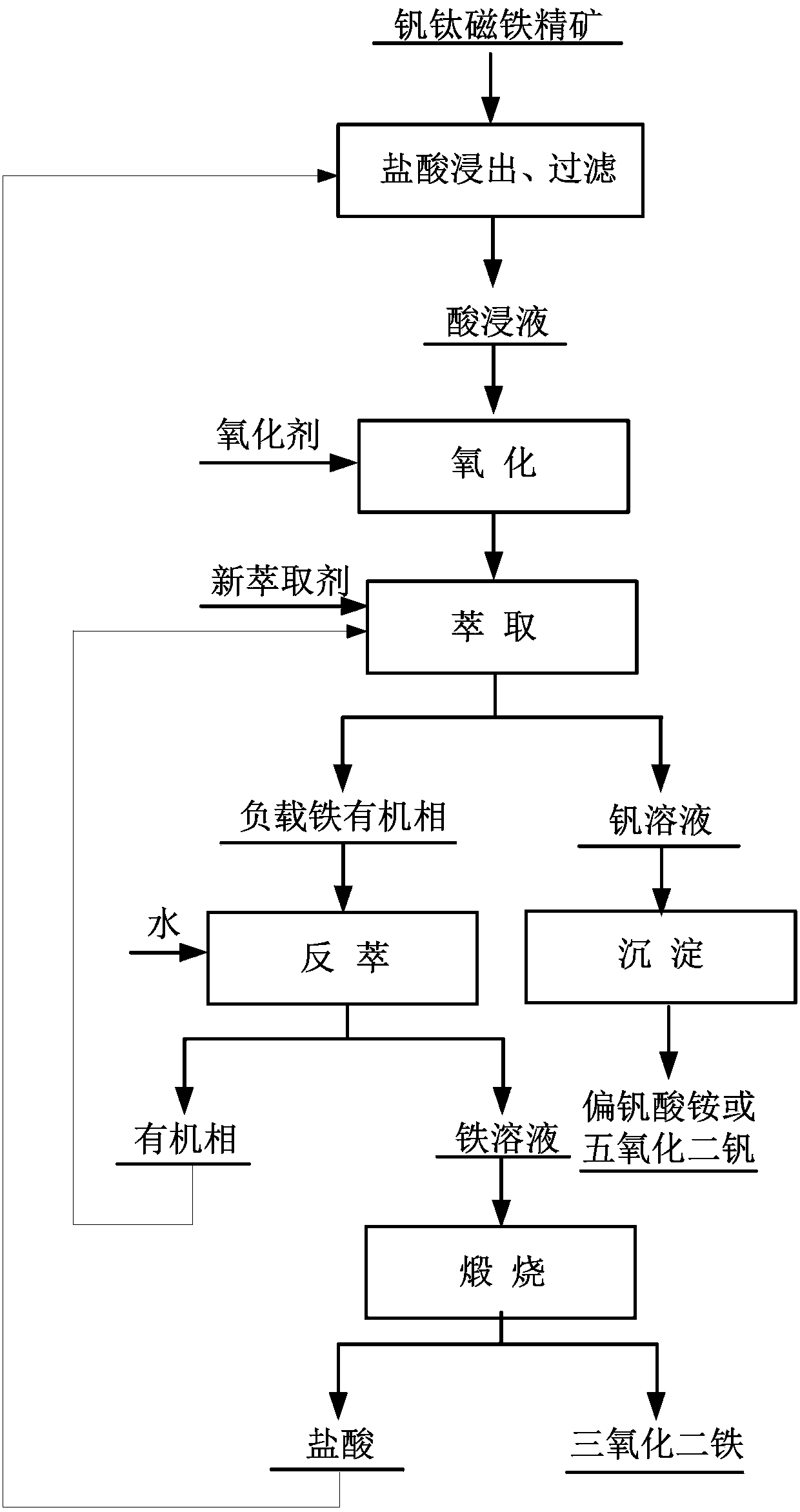

A vanadium-titanium magnetite concentrate and extraction technology, which is applied in the field of extracting iron and vanadium, can solve the problems of low product added value, low recovery rate, environmental pollution, etc., and achieve high product added value, increased vanadium recovery rate, and easy stripping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) The main components of the raw material vanadium-titanium magnetite concentrate: the mass content of TFe is 39.85%, TiO 2 The mass content of V is 28.74%, V 2 o 5 The mass content is 0.95%, and the vanadium-titanium magnetite concentrate is ground to -200 mesh 80%;

[0030] (2) Mix the finely ground vanadium-titanium magnetite concentrate with 10% hydrochloric acid, the liquid-solid ratio is 10:1, and leaching at 150°C for 5 hours to obtain the acid leaching solution;

[0031] (3) Fe in the pickling solution obtained in step (2) is replaced with potassium chlorate 2+ Oxidized to Fe 3+ ;

[0032] (4) Extract the acid dipping solution obtained in step (3) and 4-methyl-2-pentanone at a volume ratio of 0.5:1 for 5 times to obtain an organic phase and a vanadium-containing raffinate;

[0033] (5) Mix the organic phase obtained in step (4) with deionized water, wherein the organic phase: water phase = 5:1, strip twice to obtain 4-methyl-2-pentanone and acidic iron-co...

Embodiment 2

[0037] (1) The main components of raw material vanadium-titanium magnetite concentrate: the mass content of TFe is 44.23%, TiO 2 The mass content of V is 23.25%, V 2 o 5 The mass content is 1.31%, and the vanadium-titanium magnetite concentrate is ground to -200 mesh 80%;

[0038] (2) Mix the finely ground vanadium-titanium magnetite concentrate with 25% hydrochloric acid, the liquid-solid ratio is 5:1, and leaching at 120°C for 3 hours to obtain the acid leaching solution;

[0039] (3) Fe in the pickling solution obtained in step (2) is replaced with sodium chlorate 2+ Oxidized to Fe 3+ ;

[0040] (4) extracting the oxidized acid dipping solution obtained in step (3) and 4-methyl-2-pentanone at a volume ratio of 5:1 twice to obtain an organic phase and a vanadium-containing raffinate;

[0041] (5) Mix the organic phase obtained in step (4) with deionized water, wherein the organic phase:water phase=0.5:1, back extraction 5 times to obtain 4-methyl-2-pentanone and acidic ...

Embodiment 3

[0045] (1) The main components of raw material vanadium-titanium magnetite concentrate: the mass content of TFe is 50.5%, TiO 2 The mass content of V is 15.66%, V 2 o 5 The mass content is 0.80%, and the vanadium-titanium magnetite concentrate is ground to -200 mesh 80%;

[0046](2) Mix the finely ground vanadium-titanium magnetite concentrate with 36% hydrochloric acid, the liquid-solid ratio is 1:1, and leaching at 100°C for 10 hours to obtain the acid leaching solution;

[0047] (3) Fe in the pickling solution obtained in step (2) was decomposed with hydrogen peroxide 2+ Oxidized to Fe 3+ ;

[0048] (4) Extract the acid dipping solution obtained in step (3) and 4-methyl-2-pentanone at a volume ratio of 3:1 for 3 times to obtain an organic phase and a vanadium-containing raffinate;

[0049] (5) Mix the organic phase obtained in step (4) with deionized water, wherein the organic phase:water phase=2:1, back extraction 3 times to obtain 4-methyl-2-pentanone and acidic iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com