A method for recovering rare earth from the process of decomposing phosphate rock with nitric acid

A rare earth and nitric acid technology, applied in the direction of improving process efficiency, can solve the problems of low rare earth recovery rate, high content, waste water generation, etc., and achieve the effects of good extraction effect, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

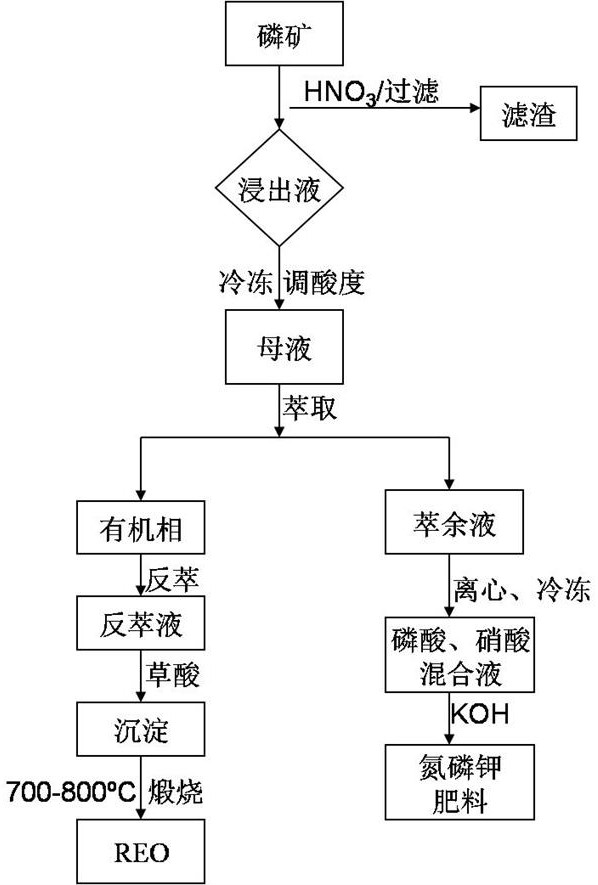

Image

Examples

Embodiment 1

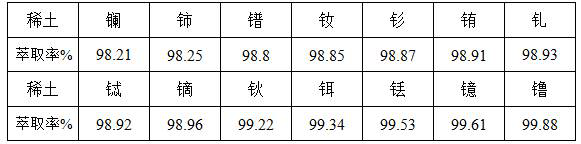

[0028] For the nitric acid leaching solution of phosphate rock at -5~-10ºC, first freeze and remove calcium, take 2.5L of mother liquor, 1.7L of phosphoric acid (85%), and 5.2L of nitric acid (65%~68%) in a 25L container , add water and mix evenly to form an aqueous phase. Prepare 0.02mol / L TODGA organic phase with n-octane as diluent. Take an equal volume of the aqueous phase and the organic phase, mix them under electric stirring at 25ºC for 30 minutes, then centrifuge for 3 minutes, take the aqueous phase, and measure the extraction efficiency of each ion as shown in the table below. The organic phase is back-extracted with deionized water at room temperature, and the stripping rate is as high as 99.%, and then recovered by precipitation with 1% oxalic acid, and the purity of the rare earth is greater than 96%.

[0029]

Embodiment 2

[0031] For the nitric acid leaching solution of phosphate rock at -5~-10ºC, first freeze and remove calcium, take 2.5L of mother liquor, 1.7L of phosphoric acid (85%), and 5.2L of nitric acid (65%~68%) in a 25L container , add water and mix evenly to form an aqueous phase. Prepare 0.1mol / L TODGA organic phase with n-octanol as diluent. Take an equal volume of the aqueous phase and the organic phase, mix them under electric stirring at 25ºC for 30 minutes, then centrifuge for 3 minutes, take the aqueous phase, and measure the extraction efficiency of each ion as shown in the table below. Use deionized water to back-extract the organic phase at room temperature, and the stripping rate is as high as 99%, with a high recovery rate, and then use 1% oxalic acid for precipitation and recovery to obtain rare earth oxides with a purity greater than 96%.

[0032]

Embodiment 3

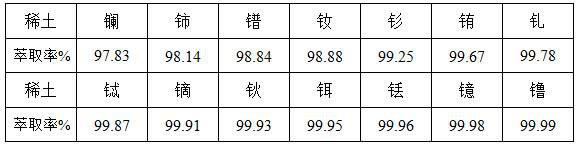

[0034] For the nitric acid leaching solution of phosphate rock at -5~-10ºC, first freeze and remove calcium, take 2.5L of mother liquor, 1.7L of phosphoric acid (85%), and 5.2L of nitric acid (65%~68%) in a 25L container , add water and mix evenly to form an aqueous phase. Prepare 0.02mol / L DMDHDGA organic phase with n-hexane as diluent. Take an equal volume of the aqueous phase and the organic phase and mix them under electric stirring for 30 minutes at 25ºC, then centrifuge for 3 minutes, take the centrifuged aqueous phase, and measure the extraction efficiency of each ion as shown in the table below. Use deionized water to back-extract the organic phase at room temperature, the stripping rate is as high as 99%, and has a high recovery rate, and then use 1% oxalic acid to precipitate and recover, and the purity of the rare earth is greater than 96%.

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com