Ultrathin carrier cell sheet and preparation method thereof

A cell sheet and carrier technology, applied in prosthetics, coatings, medical science, etc., can solve the problems of easy damage, poor mechanical properties of cell sheets, and artificial modification of cell sheets that cannot be loaded with drugs, so as to achieve precise shape control and flexibility Ease of machinability, effect of material reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Prepare an aqueous solution of gelatin with a mass fraction of 1%, wait for it to dissolve at 55°C, apply it evenly on the surface of the cover glass, put it in a vacuum drying oven, and vacuum at room temperature for 6 hours to remove the solvent.

[0041]Take out the glass slide, immerse in polystyrene sulfonate aqueous solution for 5 minutes, then immerse in water for 3 minutes, then immerse in polyallylamine hydrochloride solution for 5 minutes, and then immerse in water for 3 minutes. Carry out 15 cycles in this order, dry naturally, and sterilize with ethylene oxide gas. Wherein polystyrene sulfonate, polypropylene amine hydrochloride aqueous solution, concentration 2g / L, add 0.15M sodium chloride, adjust pH value to 3.

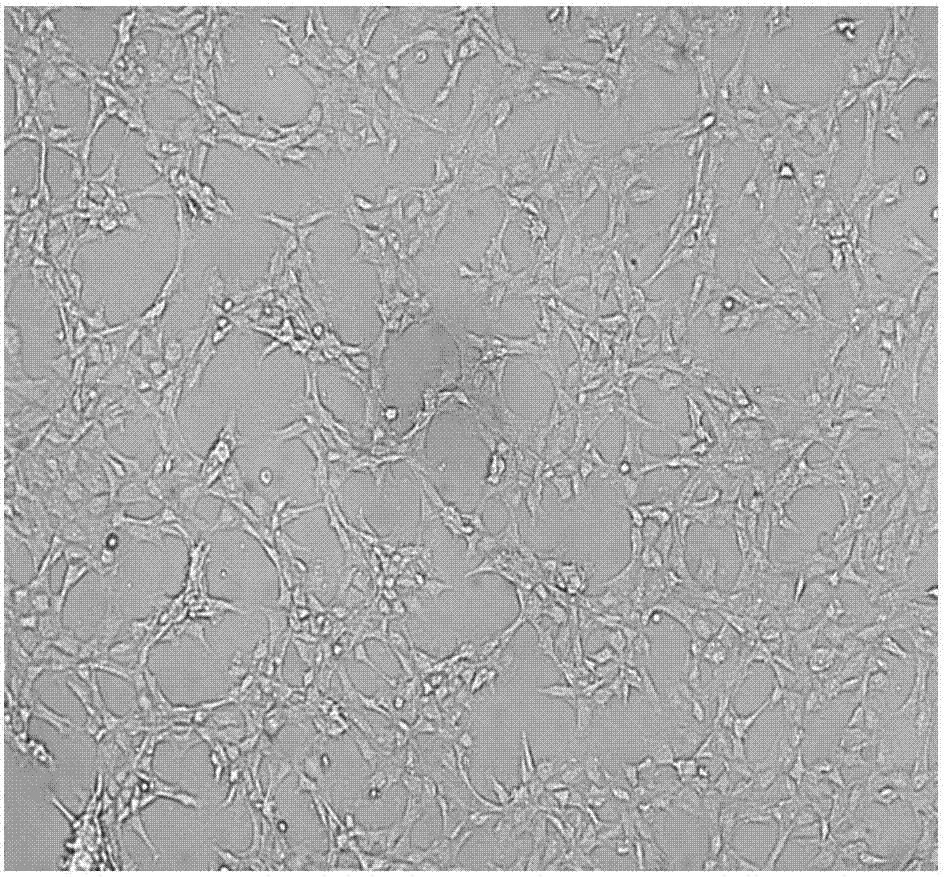

[0042] Place the glass slides obtained in the previous step in a petri dish, and add the rat-derived bone marrow mesenchymal stem cell suspension (10 4 ~10 6 cells / ml) were submerged on the surface, and cultured in a conventional cell culture i...

Embodiment 2

[0044] Prepare an aqueous solution of gelatin with a mass fraction of 15%, wait for it to dissolve at 55°C, spin-coat it on the surface of a glass slide with a coater, put it in a vacuum drying oven, and vacuum it at room temperature for 6 hours to remove the solvent.

[0045] Take out the glass slide, immerse in hyaluronic acid aqueous solution for 10 minutes, then immerse in water for 3 minutes, then immerse in lysine aqueous solution for 10 minutes, and then immerse in water for 3 minutes. Carry out 40 cycles in this order, dry naturally, and sterilize with ethylene oxide gas. Wherein hyaluronic acid, polylysine aqueous solution, concentration 1g / L, add 0.15M sodium chloride, adjust pH value to be 3.

[0046] The glass slide obtained in the previous step was placed in a petri dish, and the corneal epithelial cell suspension (10 4 ~10 6 cells / ml) were submerged on the surface, and cultured in a conventional cell culture incubator for 24 hours. The cell sheet is detached f...

Embodiment 3

[0048] Prepare a gelatin ethanol solution with a mass fraction of 5%, dissolve it at 55°C, apply it evenly on the surface of a glass slide, put it in a vacuum drying oven, and vacuum at room temperature for 6 hours to remove the solvent.

[0049] Take out the glass slide, immerse in polystyrene sulfonate aqueous solution for 20 minutes, then immerse in water for 5 minutes, then immerse in polyallylamine hydrochloride aqueous solution for 20 minutes, and then immerse in water for 5 minutes. Carry out 40 cycles in this order, dry naturally, and sterilize with ethylene oxide gas. Wherein polystyrene sulfonate, polypropylene amine hydrochloride aqueous solution, concentration 2g / L, add 0.15M sodium chloride, adjust pH value to 3.

[0050] The glass slide obtained in the previous step was placed in a petri dish, and the corneal epithelial cell suspension (10 4 ~10 6 cells / ml) were submerged on the surface, and cultured in a conventional cell culture incubator for 24 hours. The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com