Multi-material 3D printing equipment based on electro-hydraulic-power coupling jet printing

A 3D printing, electro-hydraulic power technology, applied in the field of 3D printing, can solve the problems of the high cost of the 3D printer, the long time required for material switching, and the low workpiece forming rate, so as to achieve low manufacturing costs and rapid switching. , Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

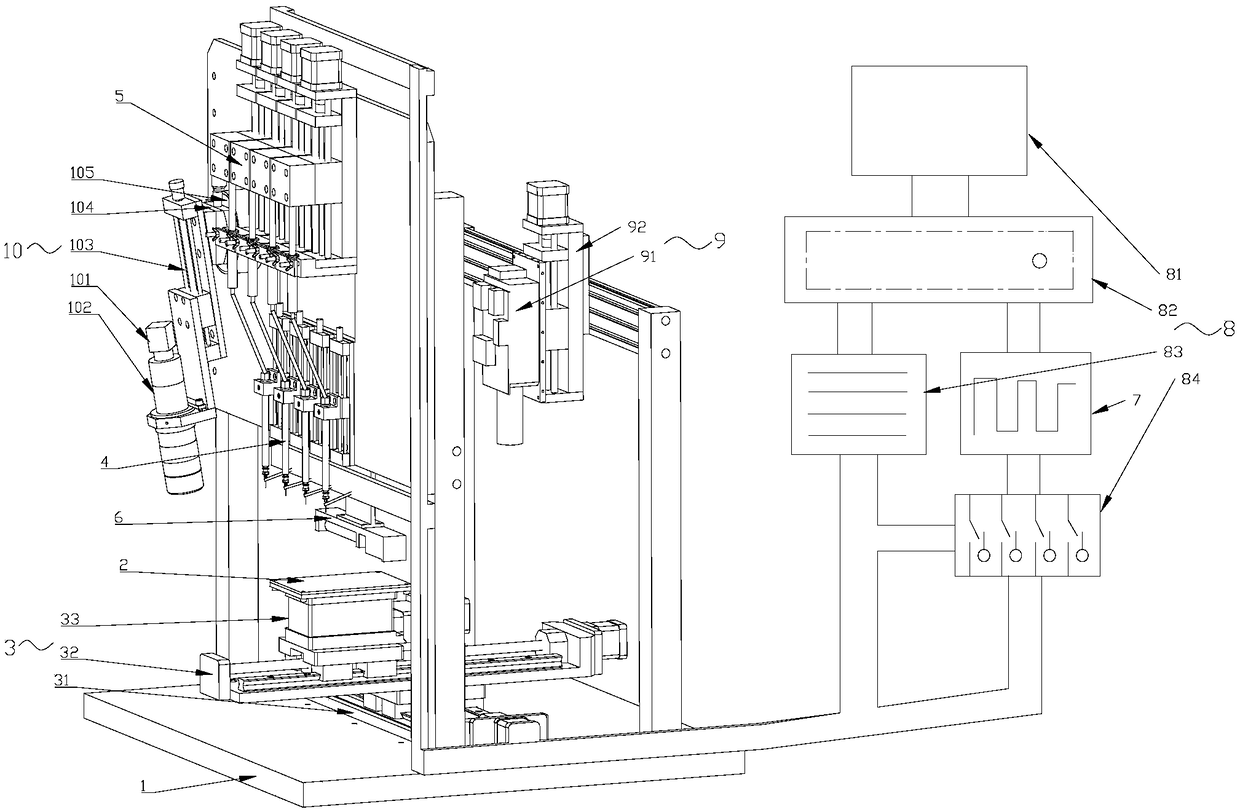

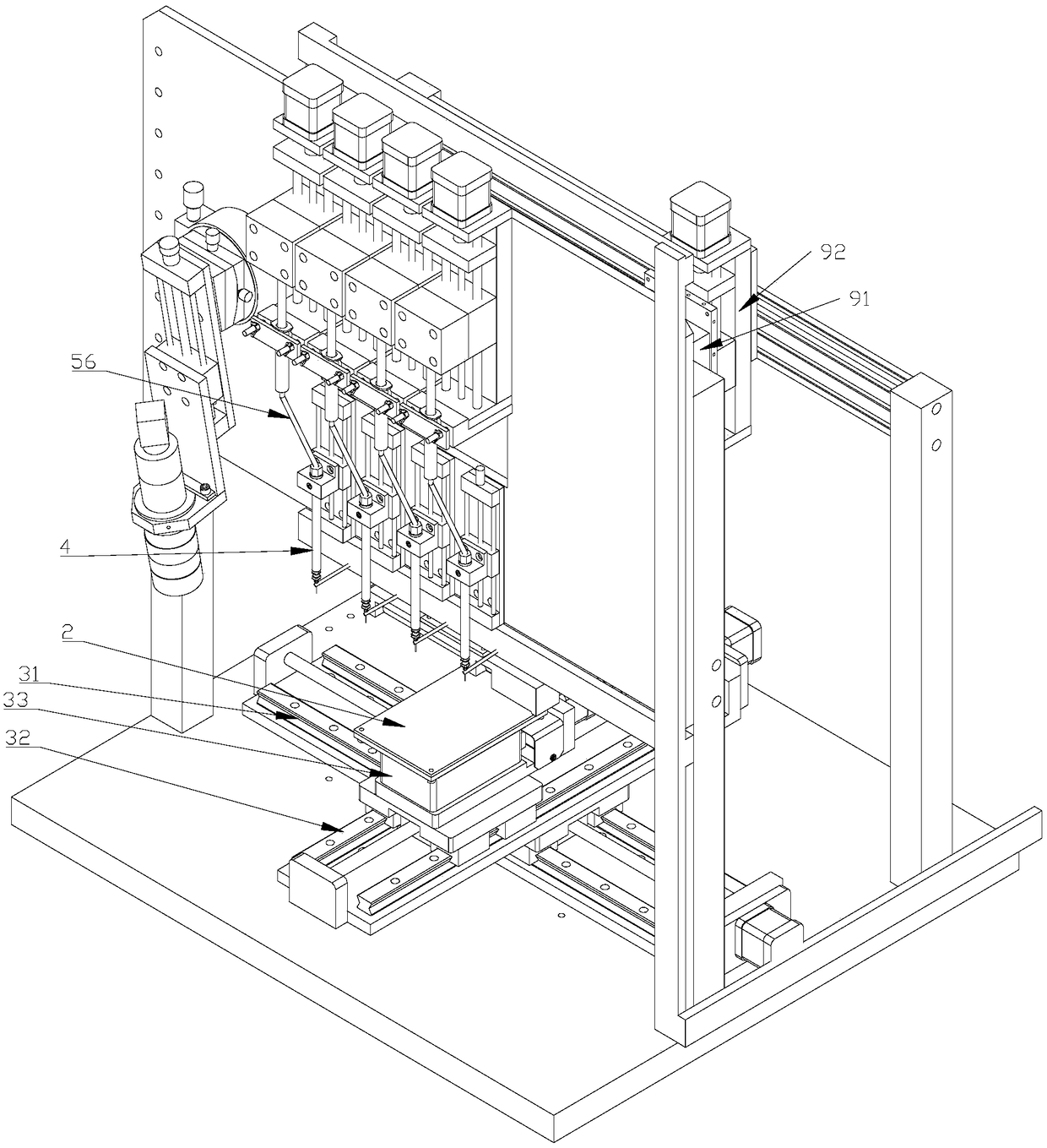

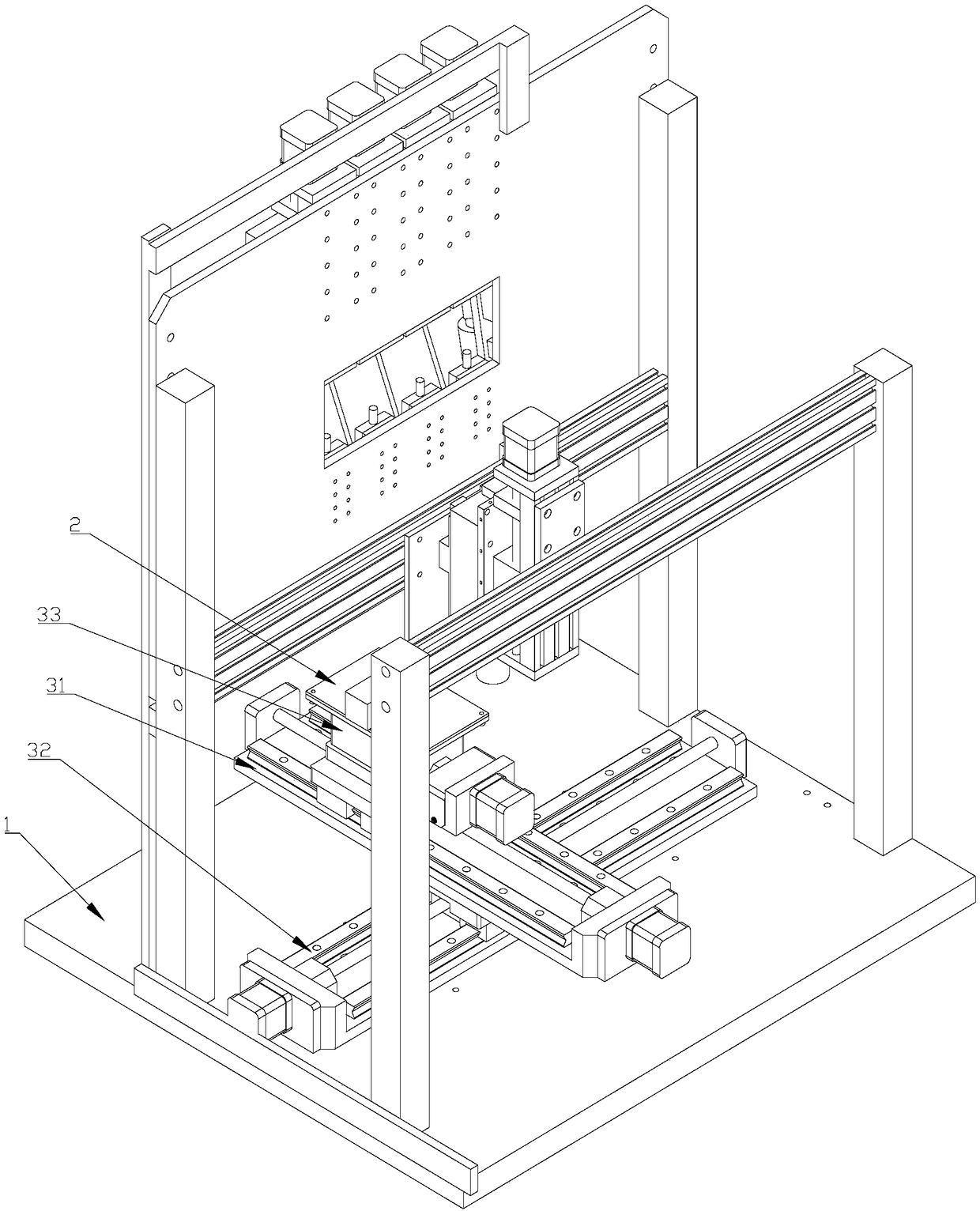

[0034] Such as Figure 1~3 As shown, the present invention includes a frame 1, a workbench 2, a mobile platform module 3, a nozzle module 4, a syringe pump module 5, a roller module 6, a DC high voltage power supply 7, a control module 8, an exposure module 9 and a CCD real-time observation system 10 .

[0035] The mobile platform module 3 is arranged on the base plate of the frame 1, and the mobile platform module 3 is fixedly connected with the workbench 2 to drive the workbench 2 to move; the nozzle module 4 is arranged on the top of the workbench 2, and the nozzle module 4 is connected to the syringe pump module 5 through a hose 56, and the dispensing needle 41 of the nozzle module 4 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com