Cylinder jet printing device and system

A cylinder and tooling technology, applied in printing devices, printing, typewriters, etc., can solve the problems of complex structure, manual missing printing, poor consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

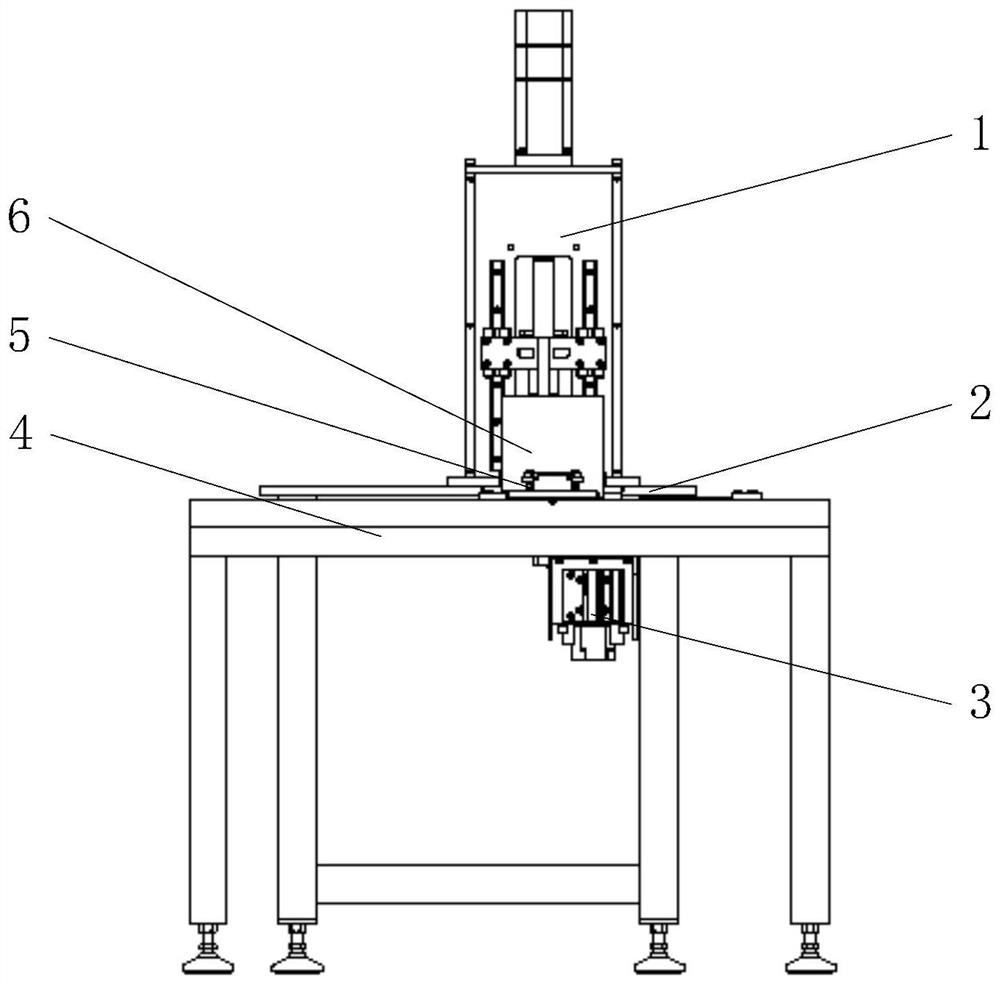

[0036] This embodiment provides a cylinder jet printing device, including a jacking and rotating mechanism 3, which is mainly used to absorb and fix the lightweight cylinder 6, move the lightweight cylinder 6 up and down, and rotate the lightweight cylinder 6 to realize Adjusting the position of the light tube 6 facilitates the printing operation of the inkjet printer 1 on the outer wall of the light tube 6 by the inkjet printing mark 104 . The jacking and rotating mechanism 3 includes a mounting bracket 301, a rotating driver, a jacking driver, a mounting plate 304 and a support seat 307;

[0037] The mounting bracket 301 is detachably mounted on the transmission line body 4 through bolts, and is located below the transmission line body 4 .

[0038] The fixed end of the jacking driver can be installed on the mounting bracket 301 through detachable connection methods such as bolts, and the jacking end of the jacking driver is provided with a mounting plate 304 through detachab...

Embodiment 2

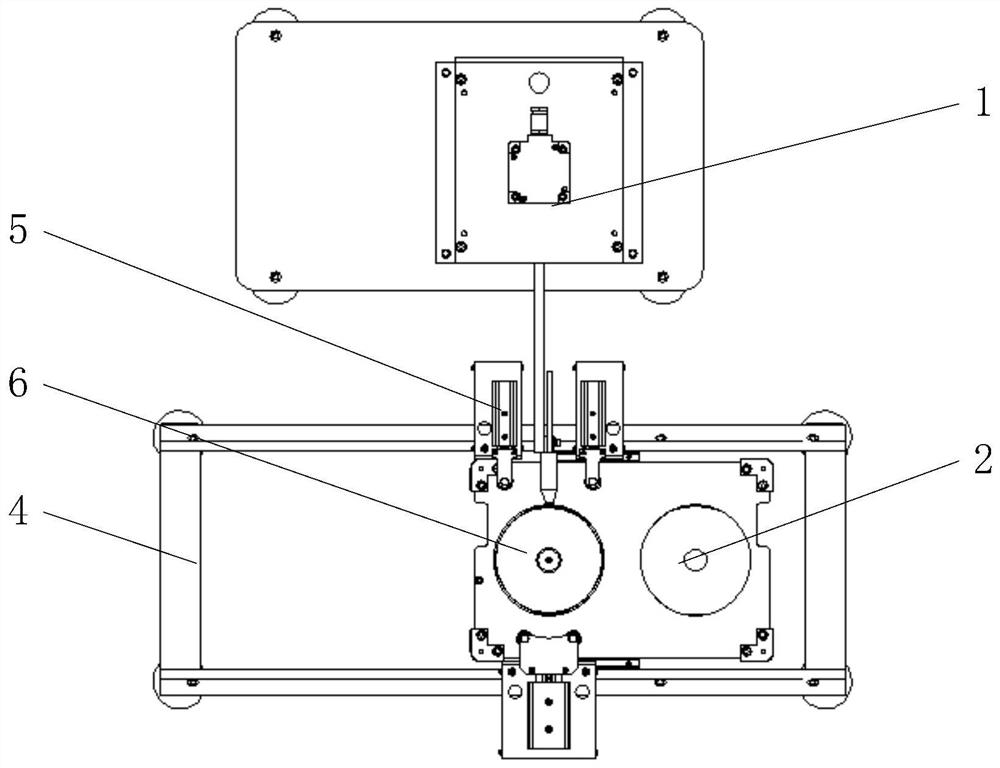

[0043] Further improvement on the basis of Embodiment 1, the jacking drive and the rotation drive can be realized by two sets of components, or can be realized by a mechanism with both jacking and rotation functions. The jacking drive and rotating drive designed in this embodiment have a simple structure, flexible operation, and low cost, and can effectively carry the light tube 6 to realize fast lifting and rotating actions, specifically:

[0044] 1. The jacking drive adopts the jacking cylinder 303, the cylinder body of the jacking cylinder 303 is installed on the mounting bracket 301 through detachable connecting parts such as bolts, and the mounting plate 304 is installed on the piston end of the jacking cylinder 303.

[0045] 2. The rotary drive includes a rotary motor 302, a driving gear 305 and a driven gear 306 installed on the mounting plate 304; the output shaft of the rotary motor 302 is rigidly connected to the driving gear 305 through a key, and the axis of the out...

Embodiment 3

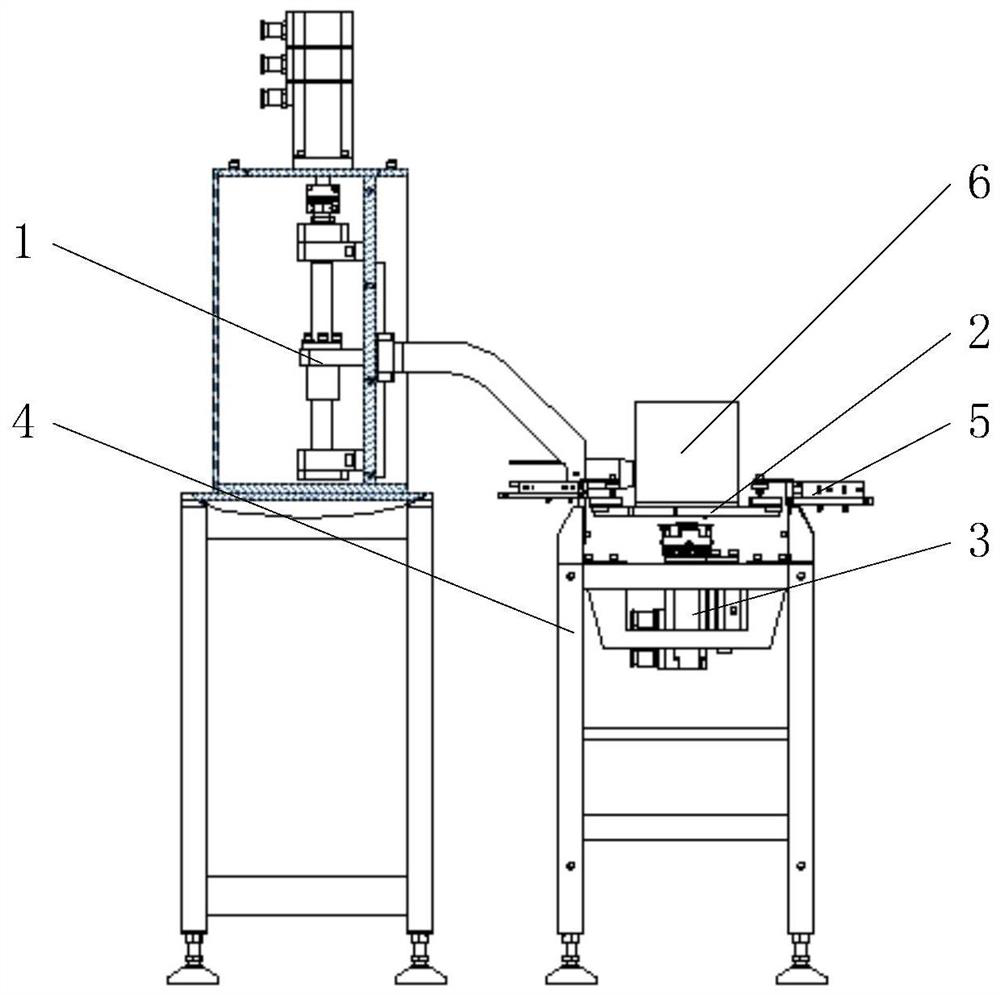

[0048] On the basis of embodiment 2, it is further improved, and also includes an inkjet printer 1. The inkjet printer 1 includes a frame 101, a lifting mechanism and a printing mark 104. The lifting mechanism is installed on the frame 101, and the lifting mechanism is used to drive The printing mark 104 moves up and down, and the ejection end of the printing mark 104 is used for printing on the outer wall of the light tube 6 .

[0049] Specifically, the design for the lifting mechanism is: the lifting mechanism includes a transmission screw 103, a linear slide rail 106, a motor 110 and a mark mounting plate 105; Rotately connect with the bearing seat 108 at both ends, the bearing seat 108 and the linear slide rail 106 at both ends are fixed on the installation vertical plate 107 of the frame 101; the sliding direction of the linear slide rail 106 is the same as the axial direction of the transmission screw rod 103 The sliding table set on the linear slide rail 106 is driven b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com