Semi-automatic multi-surface label jet printing device

A semi-automatic, jet printing technology, applied in printing, typewriter and other directions, can solve the problem of low degree of automation, achieve the effect of easy placement and improve the speed and accuracy of docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

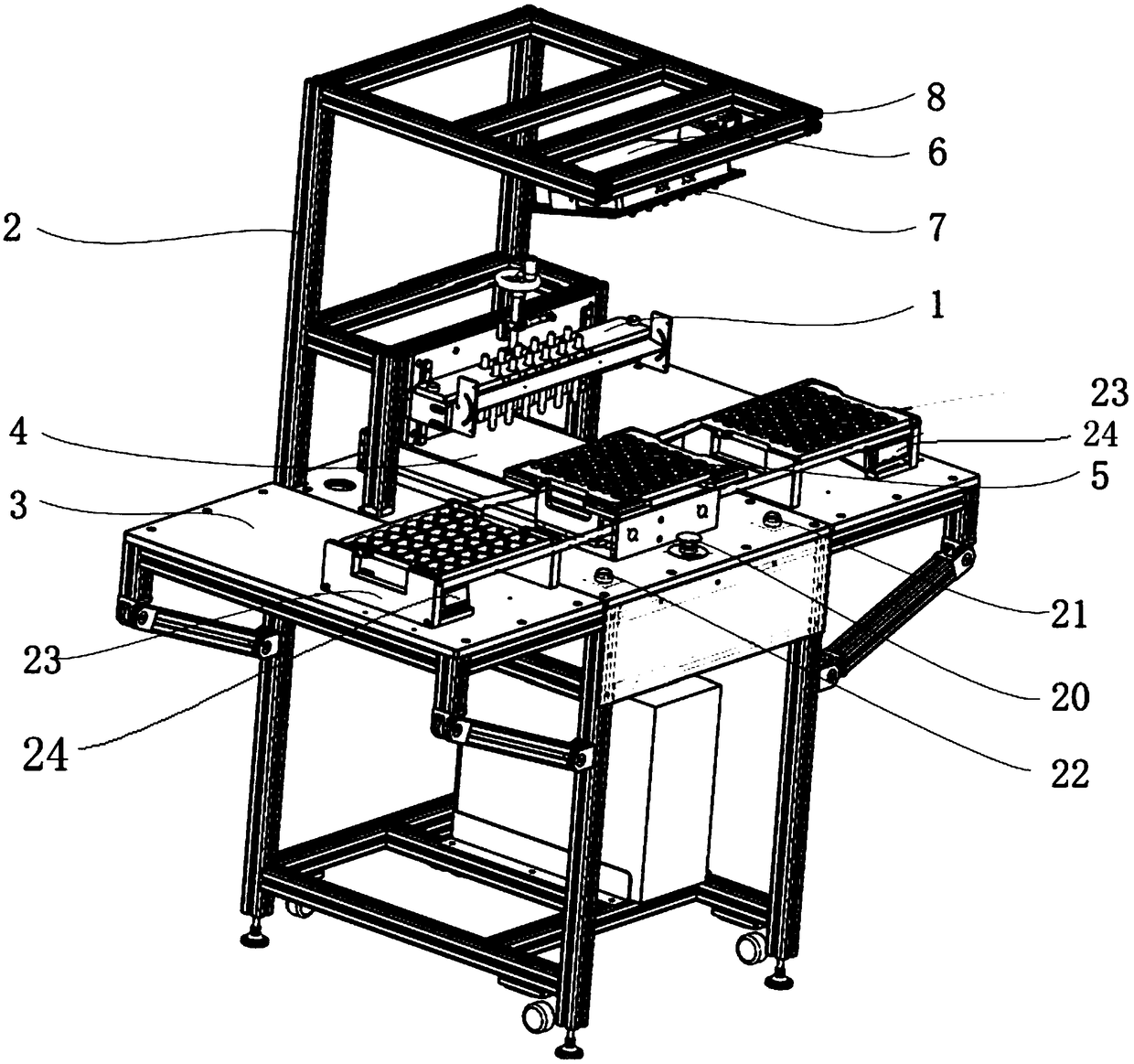

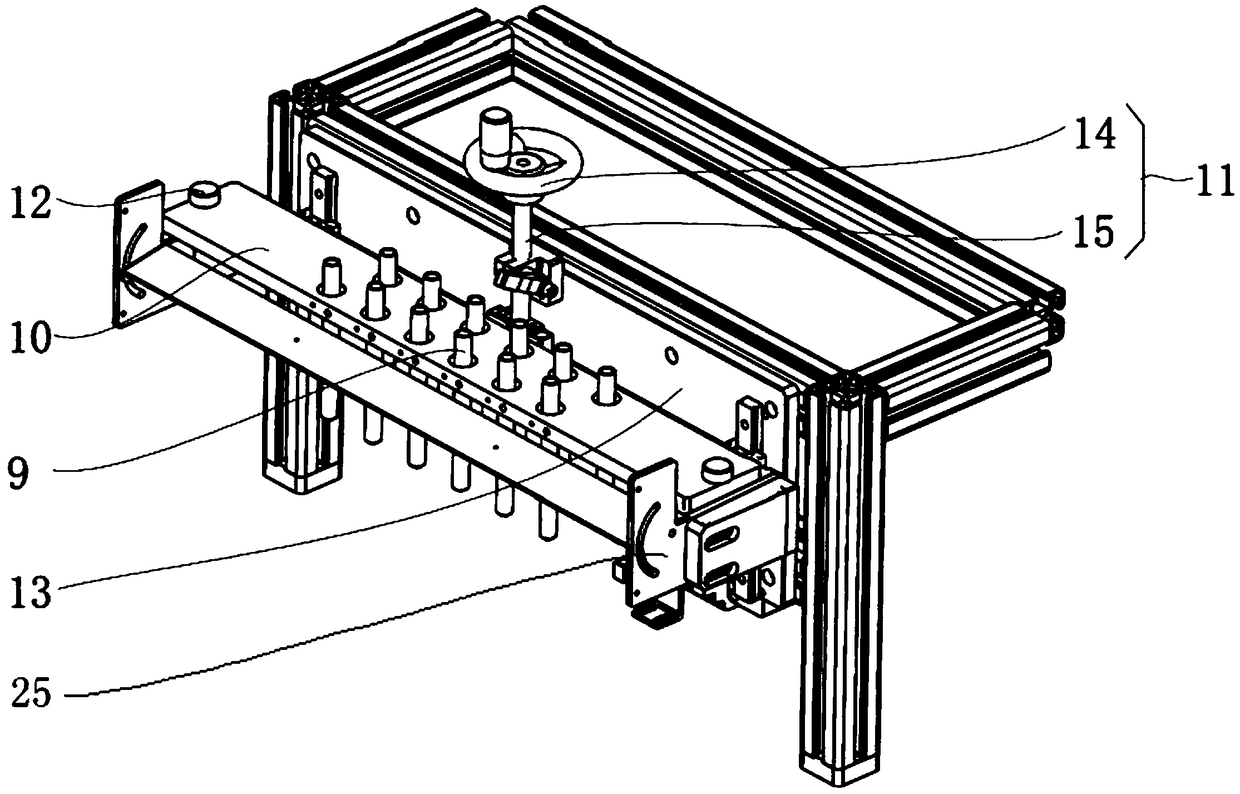

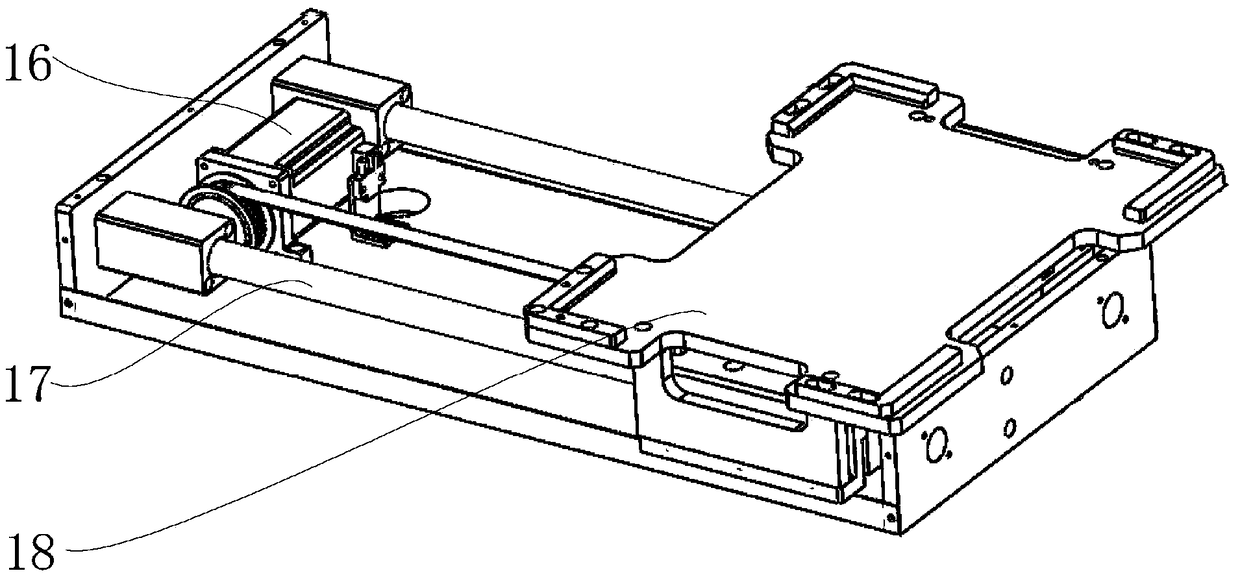

[0030] A kind of semi-automatic multi-face printing label device of the embodiment of the present invention, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes: nozzle head 1, bracket part 2, base 3, material driving part 4, main material plate 5 and material turning part 6, bracket part 2 and material driving part 4 are fixed on the upper part of base 3, and material driving part 4 is located on Below the bracket part 2, the bracket part 2 includes a vertical bracket fixed to the base 3 and a horizontal bracket positioned on the top of the vertical bracket, the nozzle head 1 is fixed on the vertical bracket, and the main material plate 5 is installed on the top of the material driving part 4, and the material The driving part 4 is used to transfer the main material board 5 to the right below the nozzle head 1; the nozzle head 1 is used to print the front side of the material on the main material board 5 which is transferred to the right below the no...

Embodiment 2

[0040] Compared with Embodiment 1, Embodiment 2 is based on Embodiment 1. Magnetic strips are provided on the edge of the turning plate 7 and the main material plate 5, which can effectively improve the speed and accuracy of the docking of the main material plate and the turning plate when turning over. sex.

Embodiment 3

[0042] Compared with Embodiment 1, the nozzle holder 10 of Embodiment 3 is also equipped with a rotating clamping plate 25 at both ends, the nozzle holder 10 can rotate on the rotating clamping plate 25, and after rotating to a predetermined position, it can be clamped by a limit device Position limit; specifically, by rotating the nozzle frame 10, the printing direction of the nozzle group 9 can be changed, so that the printing label device of the present invention can be applied to different printing materials for multi-sided printing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com