Vertical Curved Surface Printing System

A curved and vertical technology, applied in the field of vertical curved surface printing systems, can solve the problems of difficulty in finding the printing position of the nozzle, increase the difficulty of printing, etc., and achieve the effect of good printing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

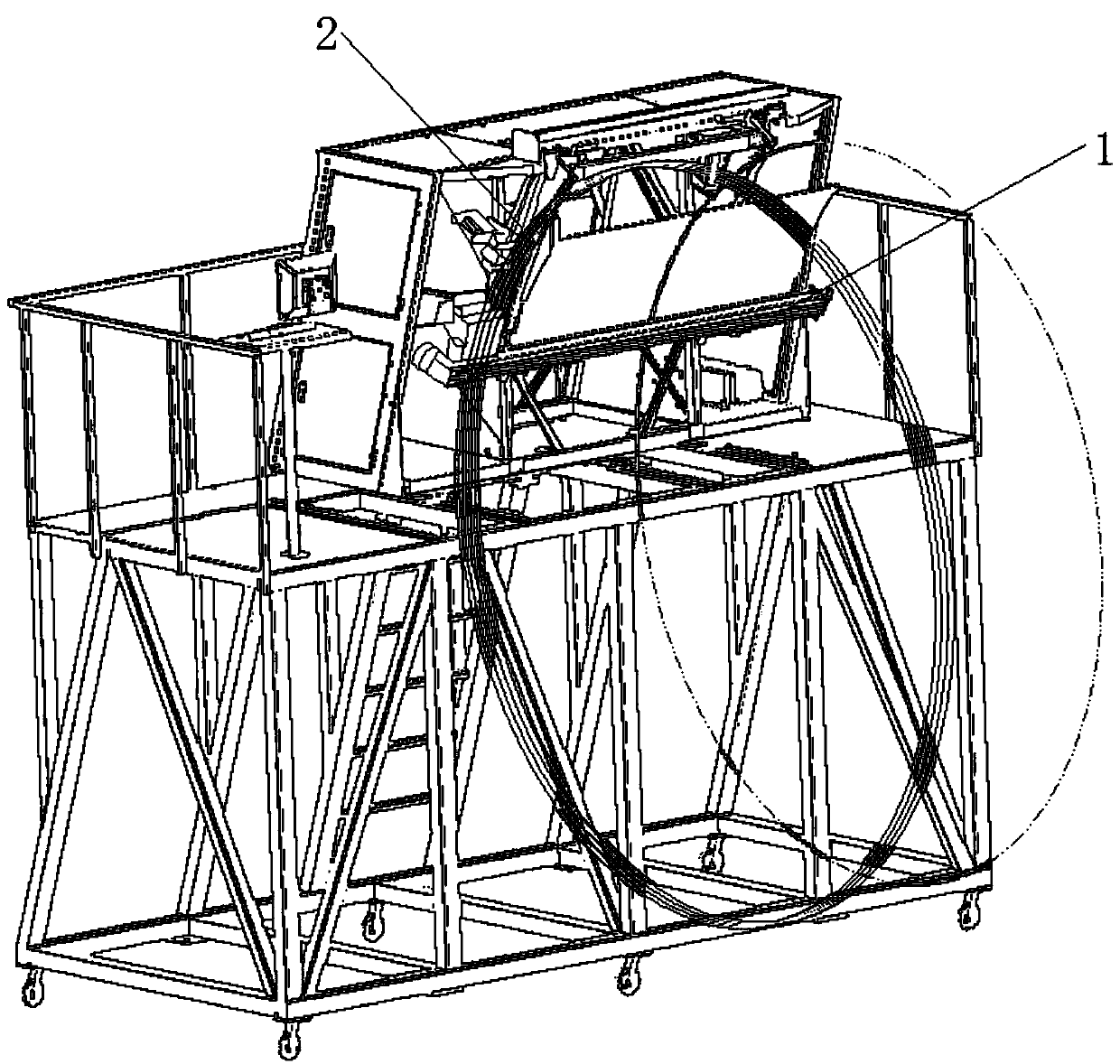

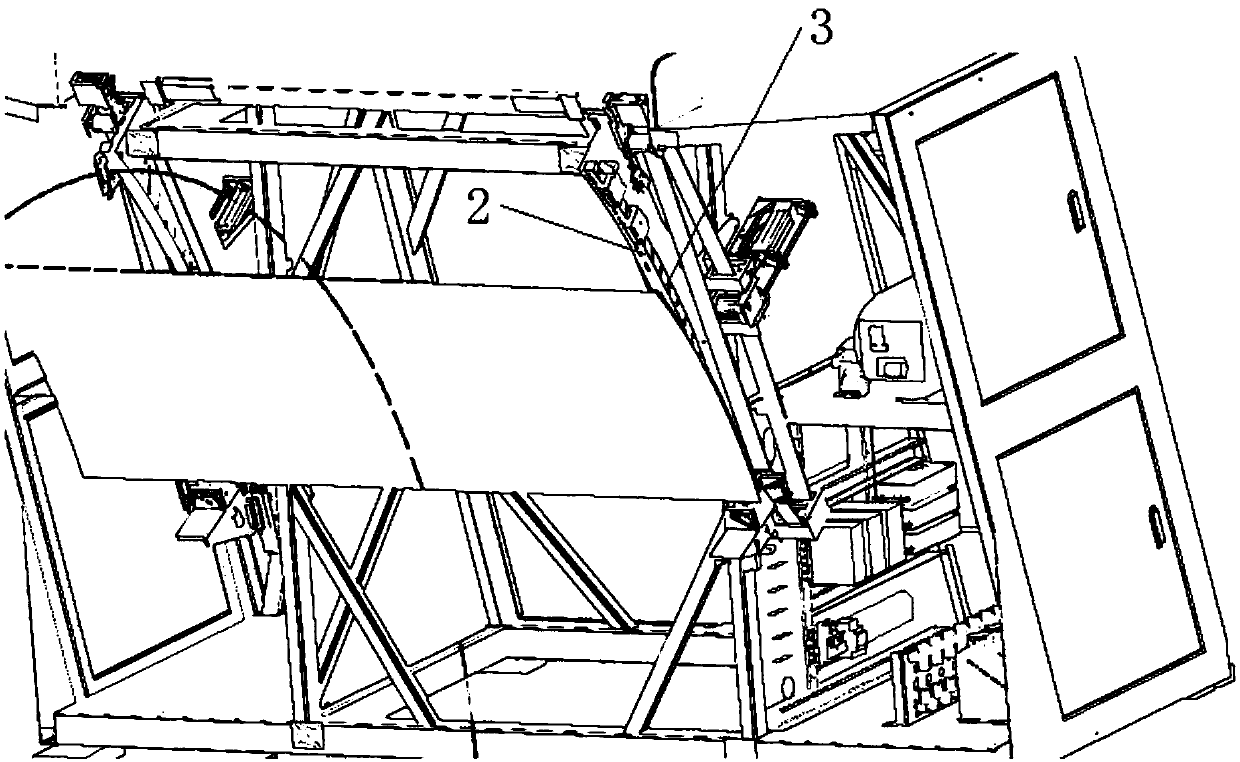

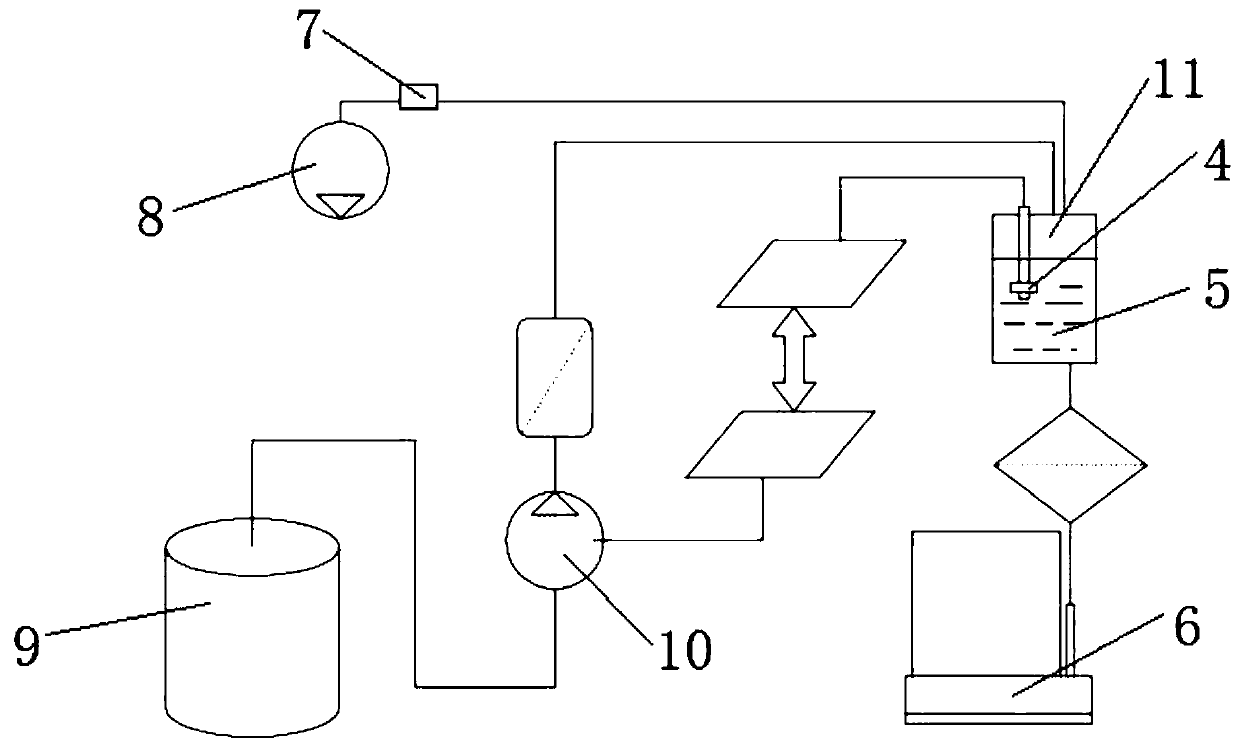

[0031] Such as figure 1 with figure 2 As shown, the present invention provides a vertical curved surface inkjet printing system, comprising: a pair of arc-shaped slide rails 2; A drive mechanism, respectively connected to the two ends of the crossbeam 1, a pair of first drive mechanisms work synchronously to drive the two ends of the crossbeam 1 to slide along the pair of arc-shaped slide rails 2 synchronously; , which is movably arranged on the beam 1, and a nozzle 6 is installed on the nozzle holder, and the nozzle 6 is connected to the ink supply system; a second driving mechanism, which is connected to the nozzle holder, to drive the nozzle holder The print head seat reciprocates along the beam 1; the control module controls the first drive mechanism, the second drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com