Hydrogenation modification method for faulty gasoline

A technology for hydrogenation upgrading and low-quality gasoline, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment. Restoring octane, achieving sulfur and olefin content effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

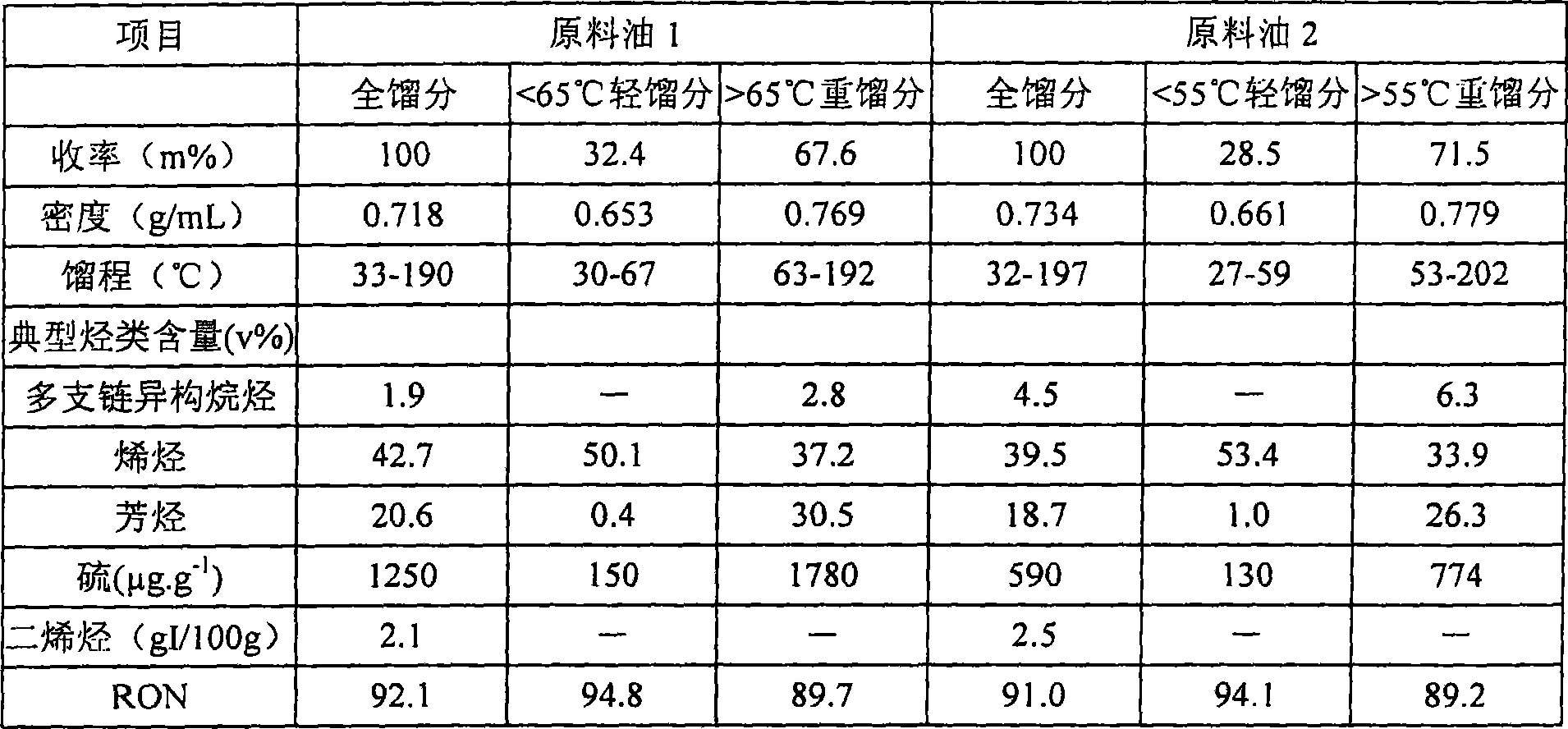

Examples

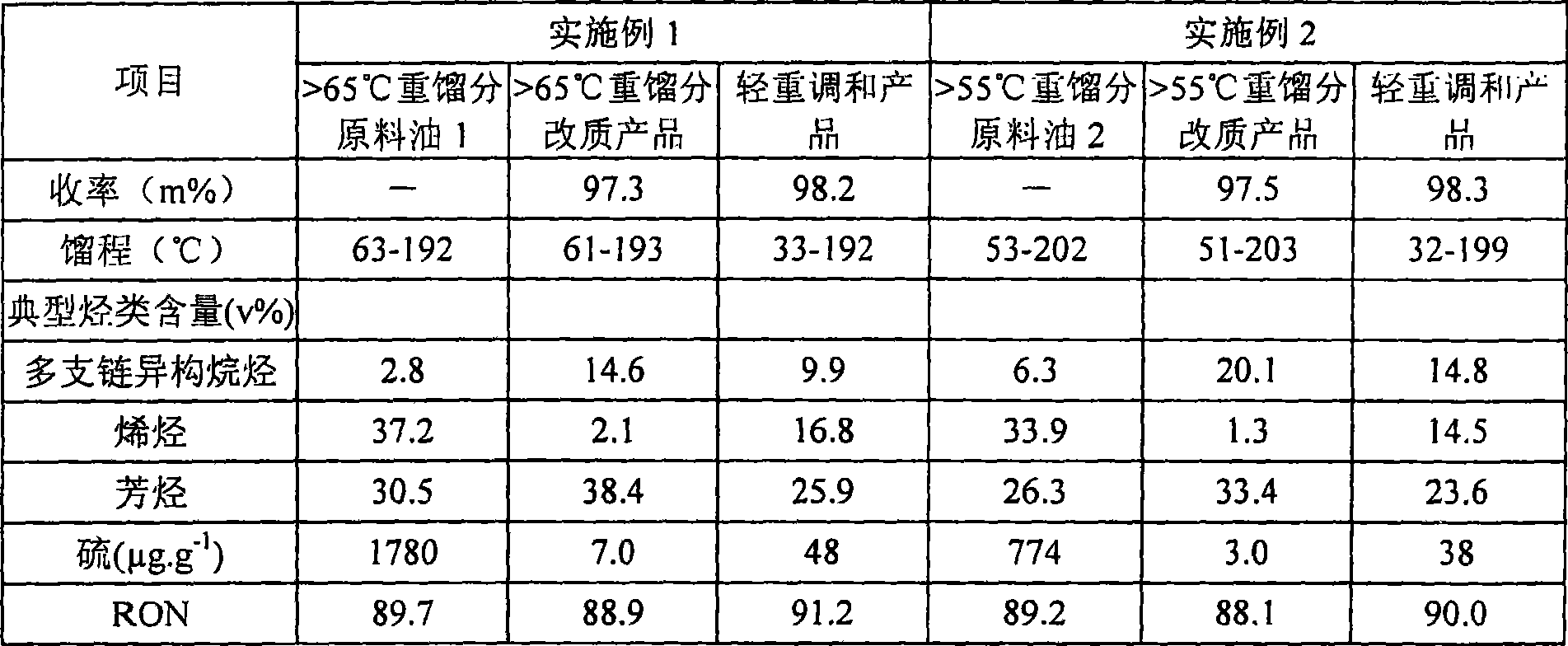

Embodiment 1

[0047] The catalyst prepared in this embodiment includes:

[0048] Based on the total weight of the catalyst, the selective hydrodesulfurization catalyst (catalyst I-A) in the first stage reaction zone comprises: 4wt.% CoO-12wt.% MoO 3 —3wt.%K 2 O—2wt.%P 2 o 5 / 67wt.%Al 2 o 3 —8wt.%TiO2—4wt.%MgO; desulfurization in the second stage reaction zone—hydrocarbon multi-branched hydroisomerization catalyst (II-A), whose composition includes: 1wt.%CoO—6wt.%MoO 3 —3wt.%NiO / 64wt.%SAPO-11 molecular sieve—22wt.%Al 2 o 3 —4wt.%TiO 2 , wherein SAPO-11 molecular sieves are formed on Al-Ti composite oxides by in-situ crystallization; supplementary desulfurization in the third stage reaction zone—hydrocarbon single-branched isomerization / aromatization catalyst (catalyst III-A), which The composition includes: 2wt.% CoO—6wt.% MoO 3 —1wt.%P 2 o 5 / 65wt.%HZSM-5—21wt.%Al 2 o 3 —5wt.%TiO 2 , which is a modified HZSM-5 zeolite-aluminum titanium catalyst.

[0049] The concrete preparat...

Embodiment 2

[0066] The difference between this example and Example 1 is that the full cut FCC gasoline (raw material oil 2) is cut into light and heavy cut FCC gasoline at 55°C, and the heavy cut FCC gasoline is used as the reaction raw material to react with the above-mentioned three-stage catalyst in sequence, and then heavy cut FCC gasoline Distillate FCC gasoline reaction products are mixed with light fraction FCC gasoline to obtain low-sulfur, low-olefin clean gasoline;

[0067] The three-stage series reaction conditions of heavy distillate FCC gasoline are as follows: the pressure of the three reactors is 1.8MPa, the volume ratio of hydrogen to oil is 500, the temperature of the first reactor is 250°C, and the volume space velocity is 5.0h -1 , the temperature of the second reactor is 290℃, the volume space velocity is 3.5h -1 , the temperature of the third reactor is 380℃, the volume space velocity is 3.5h -1 .

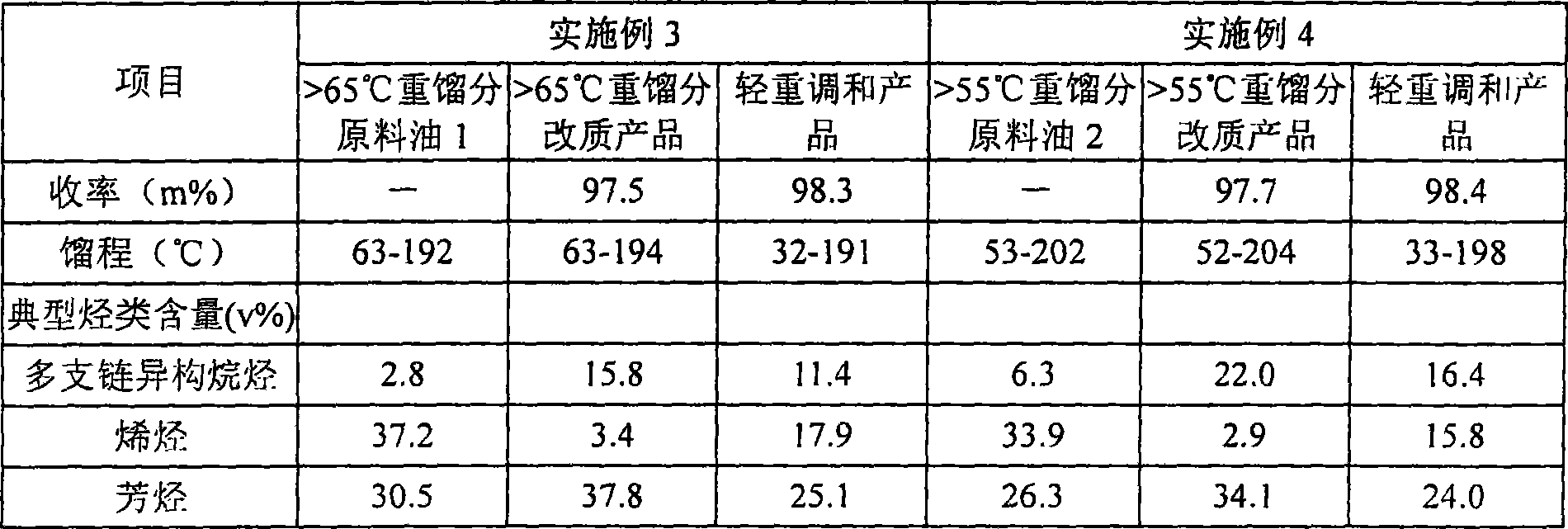

Embodiment 3

[0069] The difference between this example and Example 1 is that the first stage reaction zone is catalyst I-B: 2.5wt.% CoO—10wt.% MoO 3 —2wt.%K 2 O—3wt.%P 2 o 5 / 60wt.%Al 2 o 3 —15.5wt.%TiO 2 —7wt.% MgO, the second stage reaction zone is catalyst II-B: 2.0wt.% CoO—8wt.% MoO 3 —4wt.%NiO / 60wt.%SAPO-11—20wt.%Al 2 o 3 —6wt.%TiO 2 , the third reaction zone is Catalyst III-B: 1.0wt.% CoO—5wt.% MoO 3 —3wt.%P 2 o 5 / 60wt.%HZSM-5—22wt.%Al 2 o 3 —9wt.%TiO 2 ;

[0070] The reaction conditions are: the pressure of the three reactors is 2.3MPa, the volume ratio of hydrogen to oil is 400, the temperature of the first reactor is 260°C, and the volume space velocity is 6.0h -1 , the temperature of the second reactor is 280℃, the volume space velocity is 4.0h -1 , the temperature of the third reactor is 380℃, the volume space velocity is 3.0h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com