Construction method of through floor pipe

A construction method and pipeline technology, which are applied in the processing of building materials, construction, building construction, etc., to achieve the effects of simple mechanical equipment, good safety construction performance, and easy operation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

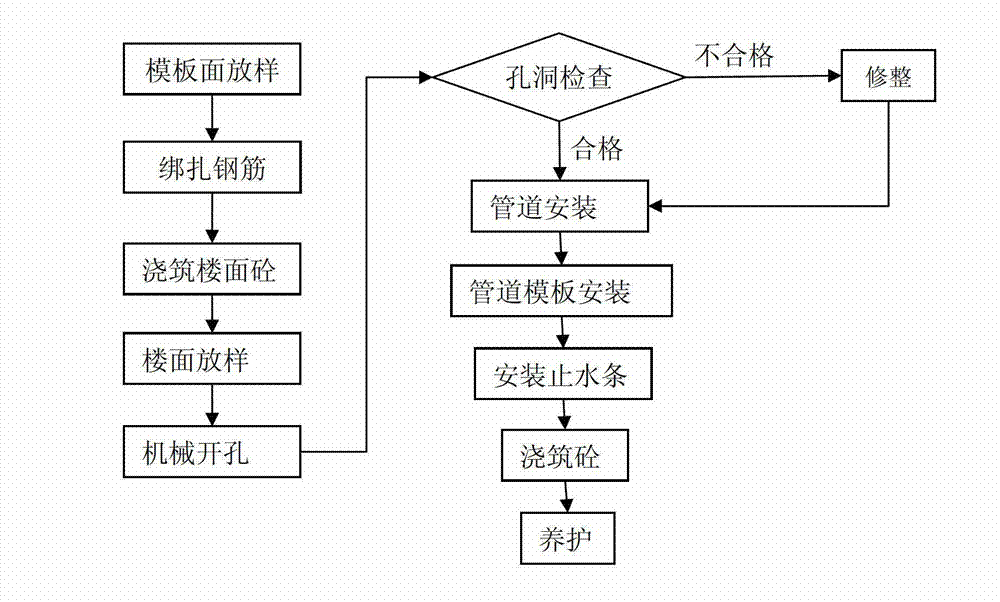

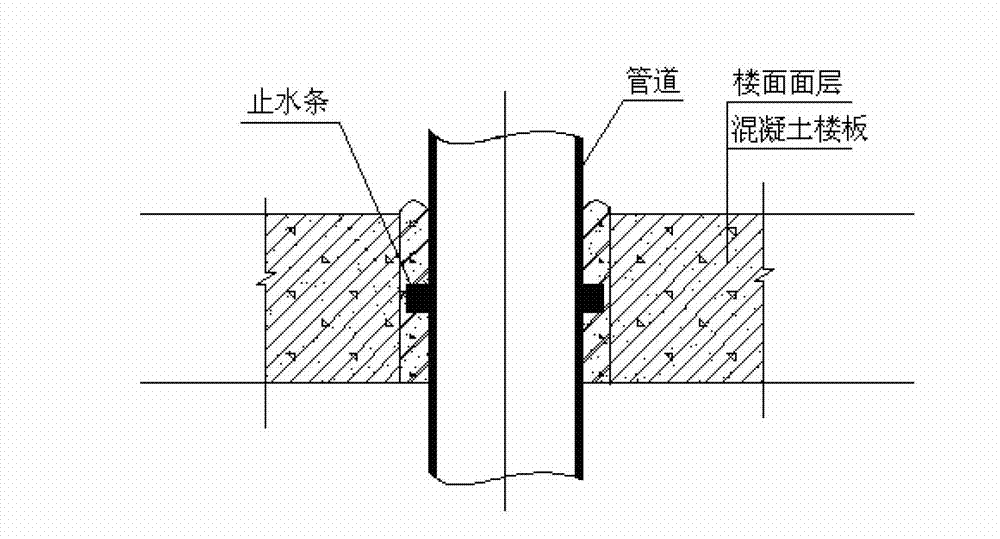

Method used

Image

Examples

Embodiment 1

[0031] material selection:

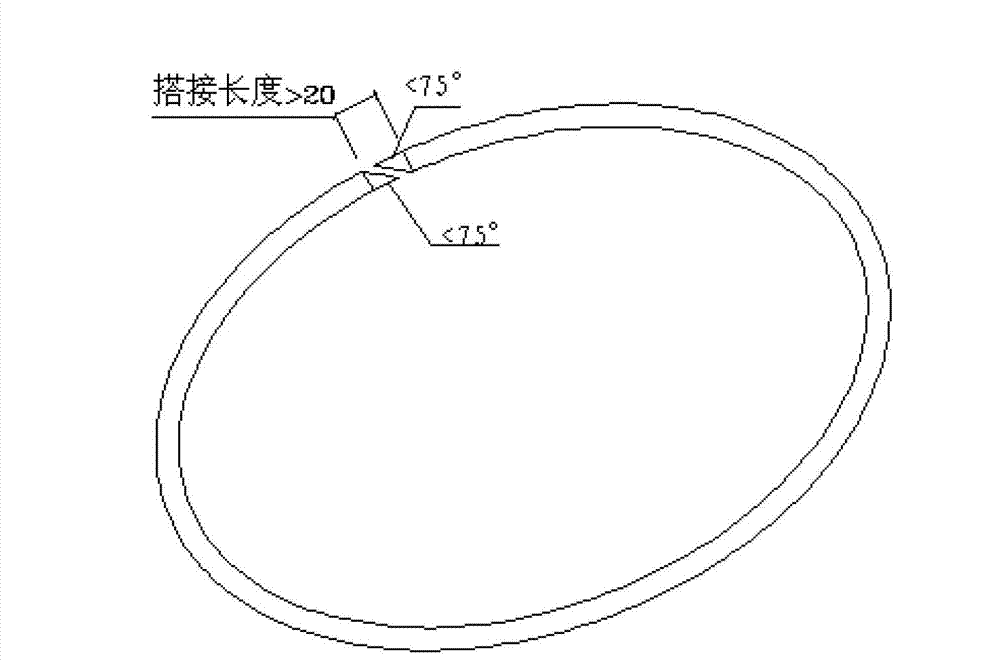

[0032] 1. The color of UPVC pipes and fittings should be the same. The inner and outer walls of pipes and fittings should be smooth and flat. The axial direction of the pipes should not be bent in different directions, and the straightness deviation should be less than 1%. The pipe ports must be flat and perpendicular to the axis; The pipe fittings should be complete without defects or deformations, and the mold joints and gates should be smooth and free of cracks.

[0033] 2. Storage and transportation of pipes and pipe fittings: pipes should be bundled according to different specifications, each bundle should be of the same length, and the weight should not exceed 50 kg; pipes should be packed separately according to different varieties and specifications, and should not be moved in bulk. When handling pipes and fittings, handle them with care to avoid oil contamination. Severe impact, contact with sharp objects, throwing and rolling are strictl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com