Second row ball filling mechanism of two-row ball bearing

A double-row ball bearing and ball technology, which is used in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems that the second row of steel balls are easily mixed, change the contact angle of the balls, and affect the quality of the finished product. The effect of setting success rate, production efficiency improvement and clearance qualification rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

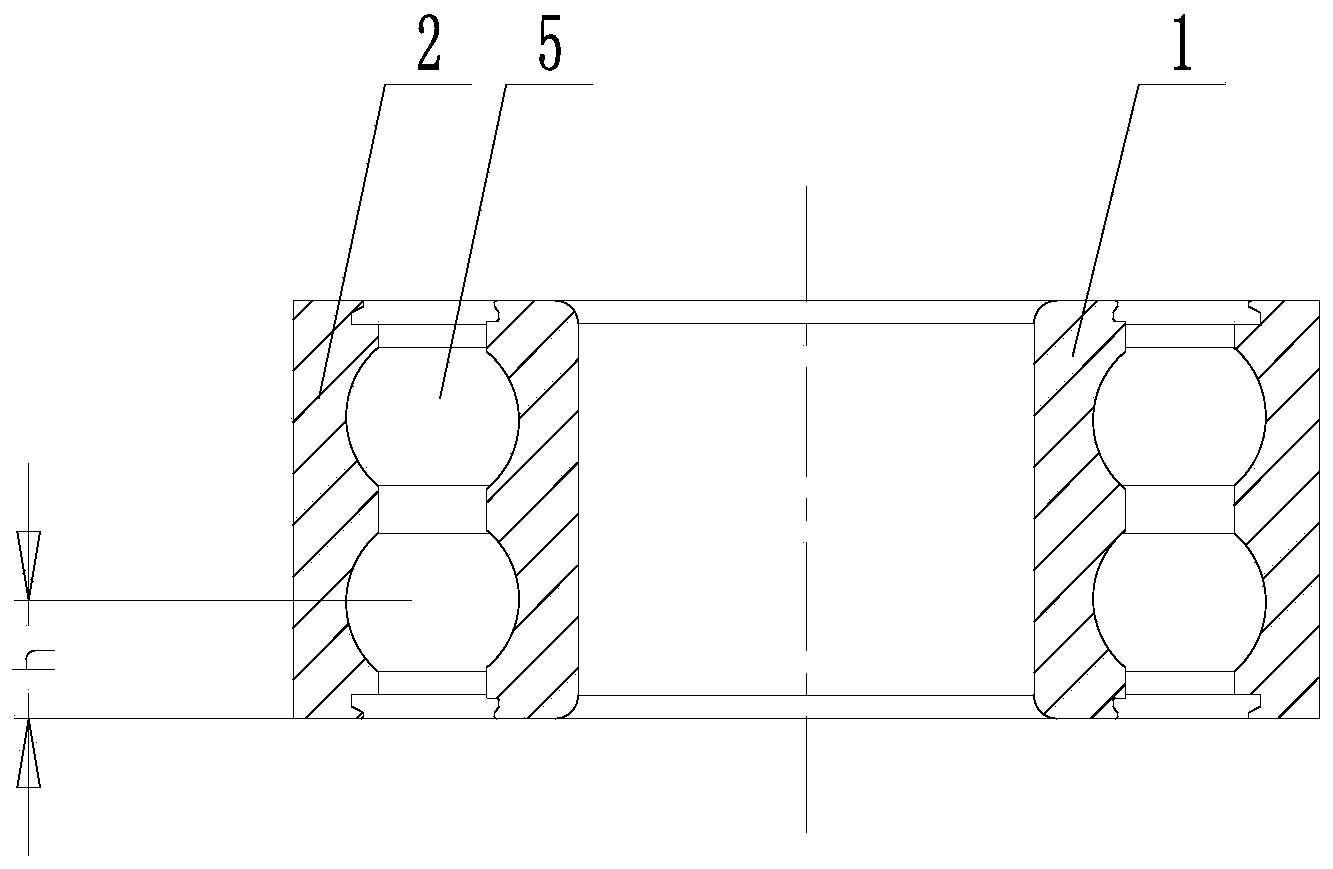

[0064] The present invention will be further described below in conjunction with accompanying drawing.

[0065] Figure 22 It is a complete set of equipment for double-row ball bearings. After this new equipment is used, the original operation mode is changed, and the balls are automatically loaded, which avoids the phenomenon of incorrect loading of steel balls and mixed steel balls due to misoperation by employees, and improves the performance of the equipment. Productivity. Specifically, six assembly bases are evenly spaced on a turntable 20 that can rotate horizontally, and the centers of all assembly bases are located on the same circle with the center of the turntable 20 as the center. As shown in the figure, the work content of each station is as follows:

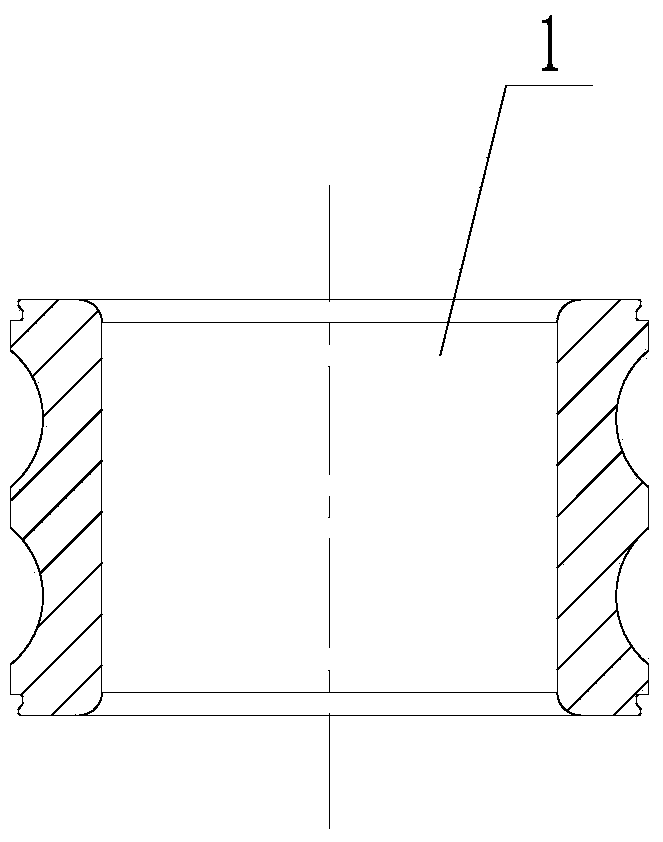

[0066] (1) Station: Measure the specific size of the current inner ring 1 conveyed from the silo, and place the inner ring 1 on the assembly base with mechanical claws;

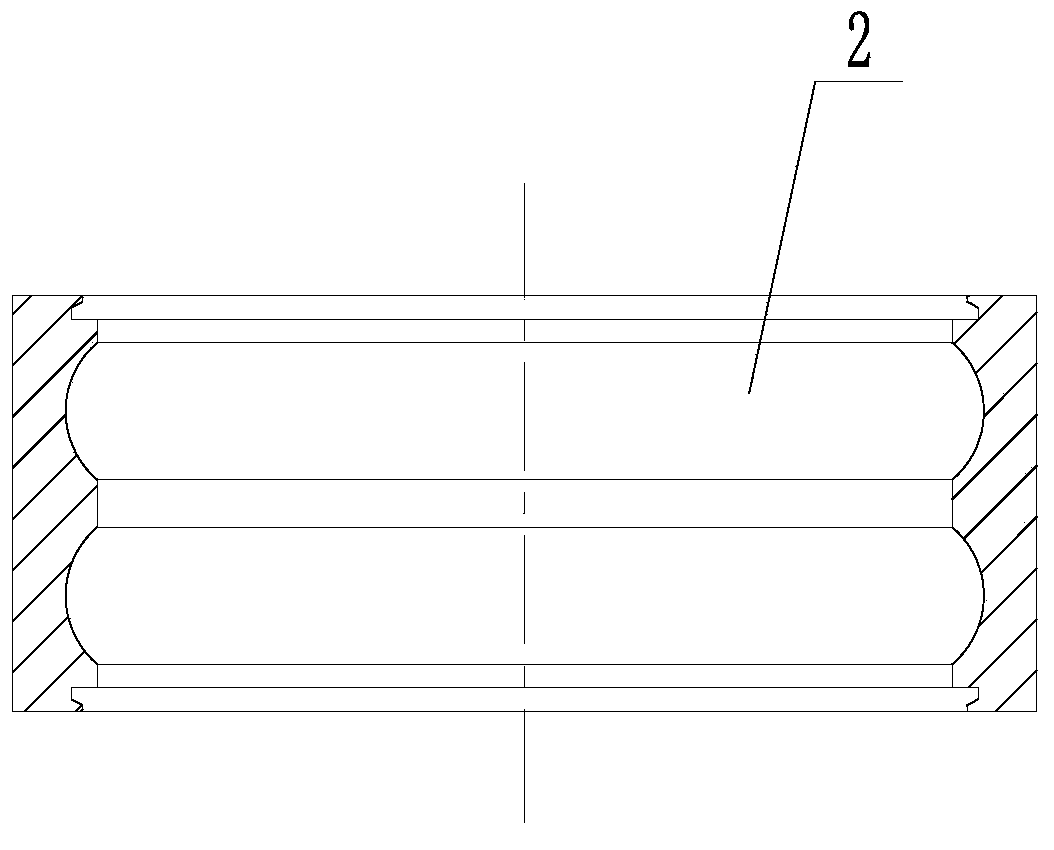

[0067] (2) Station: Measure the specific s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com