Capping method for reducing finishing quantity of slab continuous casting tailing billet and increasing temperature of billet tail

A slab continuous casting and tail billet technology, which is applied in the field of reducing the finishing amount of the slab continuous casting tail billet and increasing the capping temperature of the tail billet, and can solve the problems of reducing the specific water volume, shrinkage cavity of the tail billet, and not distinguishing steel types Information and other issues, to achieve the effect of increasing the temperature of the billet tail, reducing the finishing amount, reducing the shrinkage cavity and slag inclusion amount of the tail billet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

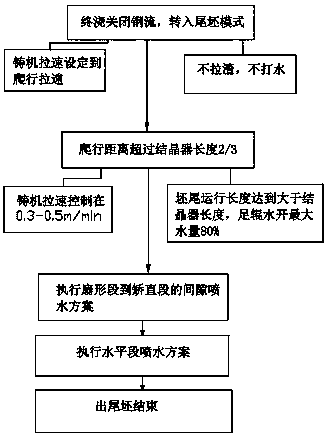

[0025] Embodiment 1: see figure 1 , a capping method for reducing the trimming amount of the slab continuous casting tail and increasing the temperature of the tail of the slab, the method is as follows:

[0026]1) During the final pouring, reduce the casting speed to 0.6 / m / min-0.8m / min, and control the casting speed to 0.3m / min-0.4m / min after maintaining for 2 minutes; close the steel flow at the final pouring, At the same time of turning the tail billet, set the casting speed of the continuous casting machine to the crawling speed, track the distance of its crawling speed (generally 0.1m / min), and the length of the crawling speed running interval is 2 / 3 of the mold length; this interval Take no slag, no water operation.

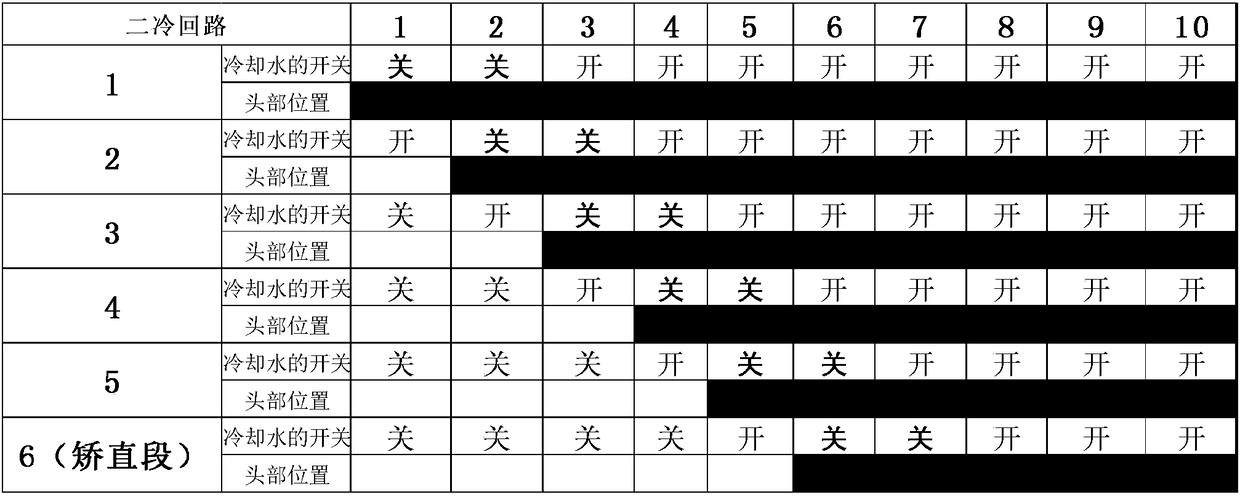

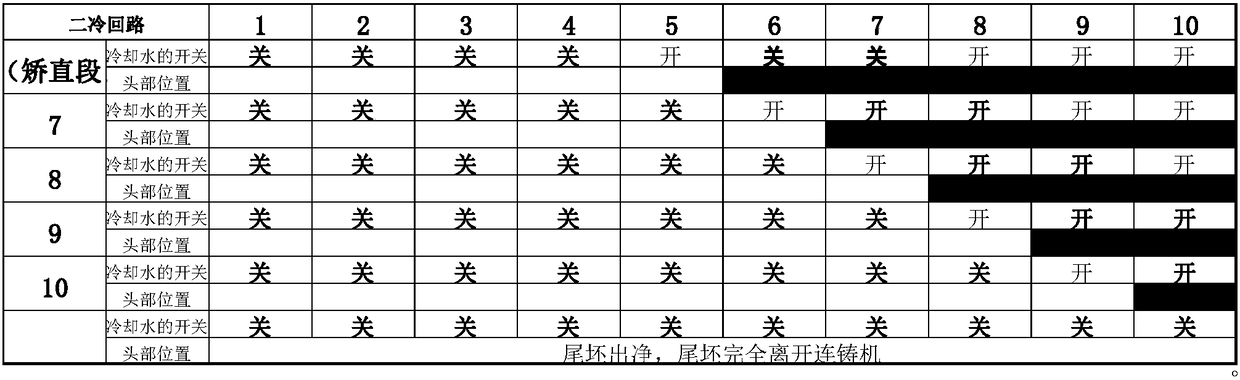

[0027] 2) When the running distance of the tail billet crawling speed exceeds 2 / 3 of the mold length, control the casting machine casting speed to run at a low casting speed of 0.3-0.5m / min, and track its running length. After the length of the crystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com