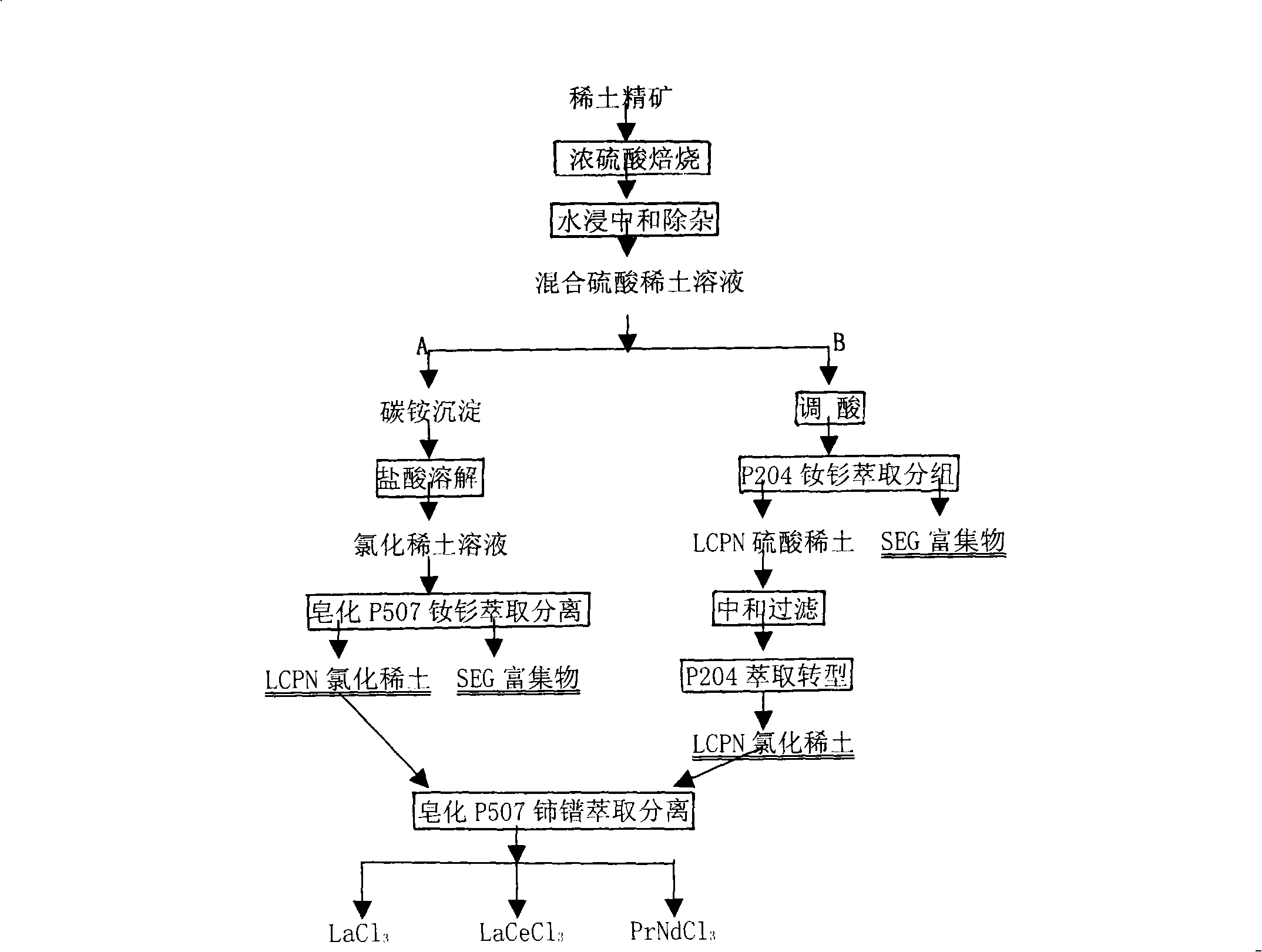

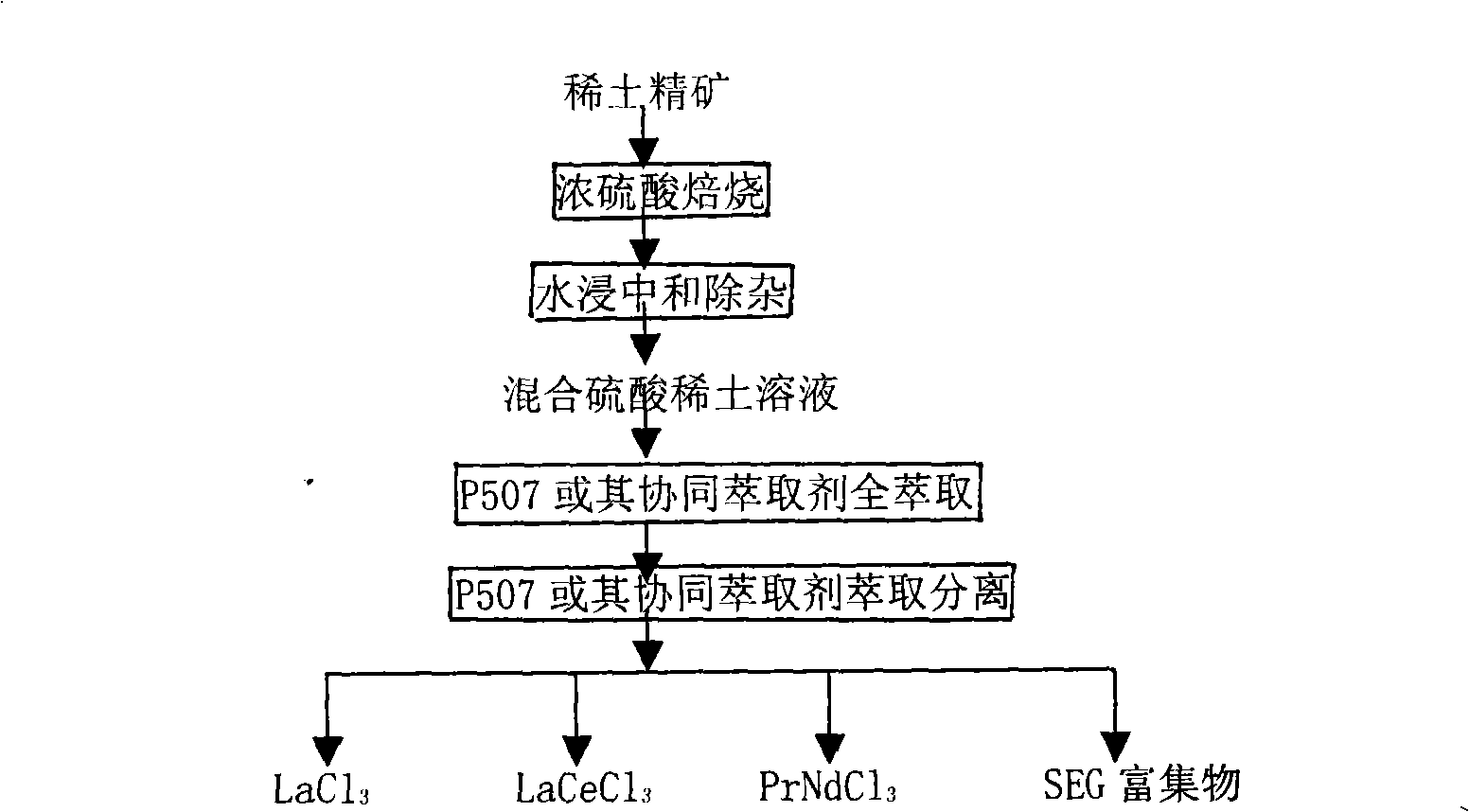

Process for solvent extraction separation purification of rare earth element

A rare earth element and process method technology, applied in the field of solvent extraction, separation and purification of rare earth elements, can solve the problems of high acid-base consumption, pollution, etc., and achieve the effects of less acid-base consumption, simple and flexible process, and easy back extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

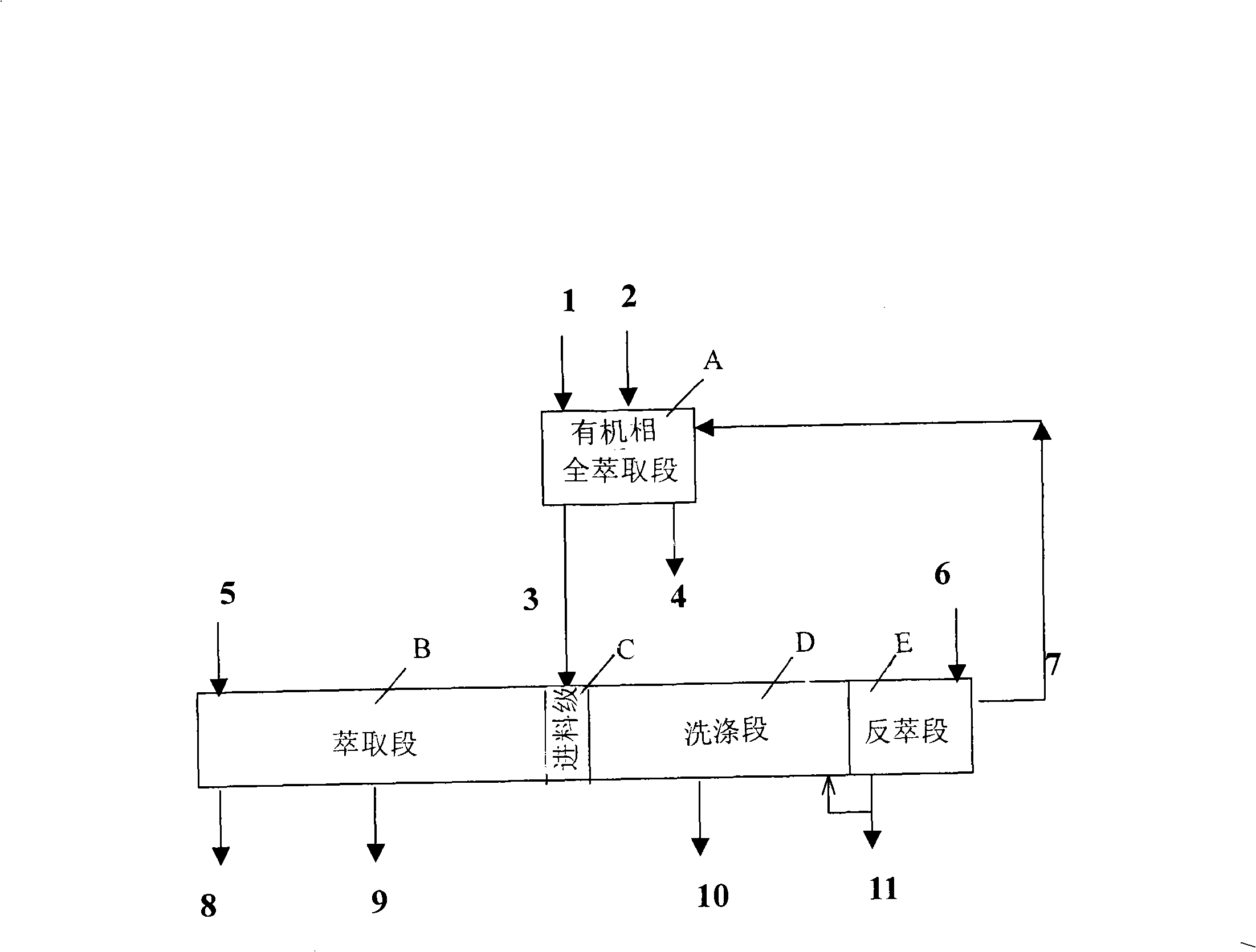

Method used

Image

Examples

Embodiment 1

[0035] The raw material is bastnaesite (REO 60%), and after sulfuric acid roasting, water immersion, neutralization and impurity removal, a mixed rare earth sulfate solution is obtained. The acidity is pH 4, and the main components are REO 0.274mol / L, Fe2 2 o 3 98%, (Sm-Y) 2 o 3 2%; the organic phase is P507 (diluted with kerosene), and its concentration is 1.5mol / L.

[0036] (1) Magnesium oxide is slurried with mixed sulfuric acid rare earth solution and water. In the slurry, the rare earth REO content is 0.121mol / L, and the magnesium oxide content is 0.8wt%. The slurry and the organic phase are mixed to extract the rare earth, and the mixing volume ratio is the extraction agent. / slurry=1 / 1.5, the temperature in the tank is 30°C, after 4 stages of co-flow extraction, 2 stages of clarification, the concentration of REO in the loaded organic phase is 0.179mol / L, and the concentration of REO in the raffinate aqueous phase is 0.001mol / L The recovery rate of L rare earth is 9...

Embodiment 2

[0040] The raw material is bastnaesite and monazite mixed rare earth ore (REO 50%). After sulfuric acid roasting, water immersion, neutralization and impurity removal, a mixed rare earth sulfate solution is obtained. The acidity is pH 4.5, and the main component is REO 0.243mol / L , Fe2 2 o 3 76%, (PrNdSm-Y) 2 o 3 24%; the organic phase is a synergistic extractant (diluted with kerosene) composed of 60% P507 and 40% P204, and its concentration is 1.3mol / L.

[0041] (1) The organic phase is mixed with the mixed rare earth sulfuric acid solution and light burnt magnesite to extract the rare earth. The magnesium oxide content in the water phase is 1.6wt%, and the mixing volume ratio is extractant / water phase=1.5 / 1. flow, 2-stage counter-current extraction, 2-stage clarification, the concentration of REO in the loaded organic phase is 0.161mol / L, the concentration of REO in the raffinate aqueous phase is 0.0005mol / L, and the recovery rate of rare earth is 99.8%.

[0042] (2) L...

Embodiment 3

[0046] The raw material is monazite (REO 60%). After sulfuric acid roasting, water immersion, neutralization and removal of impurities, a mixed rare earth sulfate solution is obtained. The acidity is pH 4.0, and the main components are REO 0.192mol / L, Fe2 2 o 3 76%, (PrNd) 2 o 3 22%, (Sm-Y) 2 o 3 2%; the organic phase is P507 diluted with kerosene, and its concentration is 1.5mol / l.

[0047] (1) Magnesium oxide is slurried with a mixed sulfuric acid rare earth solution, and the magnesium oxide content is 1.27wt% in the slurry, and the slurry and the organic phase are mixed to extract the rare earth, and the mixing volume ratio is extractant / slurry=1 / 1, and the temperature in the tank is 35°C, after 3 stages of co-flow, 2 stages of countercurrent extraction, 2 stages of clarification, the concentration of REO in the loaded organic phase is 0.191mol / L, the concentration of REO in the raffinate water phase is 0.001mol / L, 70% raffinate water The recovery rate of rare earth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com