Method for preparing photocatalytic material with multi-component porous classification structure

A hierarchical structure, multi-component technology, applied in the field of photocatalysis, can solve the problems of limited popularization and application, and the application scope is not expanded to treat organic pollutants, and achieve the effects of low cost, excellent performance, simple and flexible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

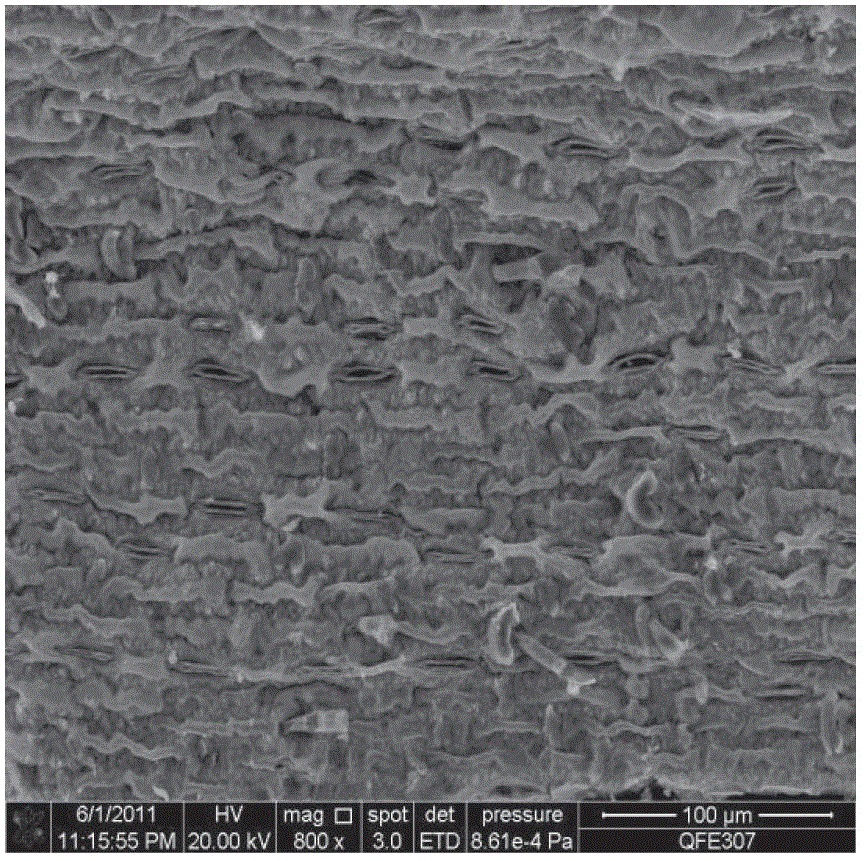

[0032] First, the natural corn leaves were cleaned to remove surface dust, and then soaked in a freshly prepared PBS buffer solution (pH 7.2-7.4) at 4°C for 12 hours, washed with distilled water, and stored at 0°C until use. After taking it out, put it at room temperature and soak it in 5% HCl solution for 3 hours until the green leaves turn yellowish brown completely, and its scanning electron micrograph is as follows: figure 1 shown.

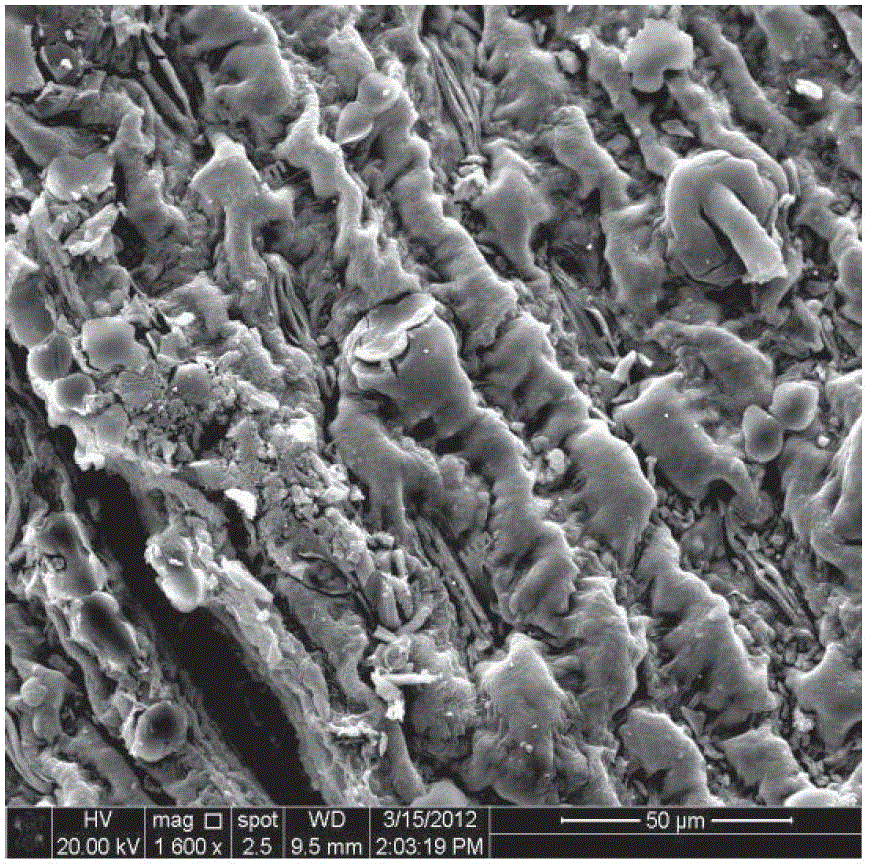

[0033] After cleaning the surface of the natural plant leaves, soaking in the metal precursor impregnation solution, hydrolyzing, and then calcining to obtain a metal oxide nanomaterial with a porous hierarchical structure; then, using the metal oxide nanomaterial as a matrix, the matrix material Further impregnating, drying and calcining in the noble metal precursor solution to obtain a composite material with a multi-component porous hierarchical structure.

[0034] Vacuum soak the above pretreated blades in 5% TiCl 3 24 hours in the aqueo...

Embodiment 2

[0038] Natural corn leaves were washed to remove surface dust, then soaked in freshly prepared PBS solution at 4°C for 12 hours, washed with distilled water, and stored at 0°C until use. After being taken out, the fixed leaves were further soaked in 5% HCl solution for 4 hours to carry out pickling treatment.

[0039] Under vacuum conditions, the leaves after the above pretreatment were soaked in 5% TiCl 3 Dehydration in the air after 24 hours in the aqueous solution; Afterwards, the leaves were placed in tetra-n-butyl titanate / absolute ethanol / acetylacetone solution (volume ratio: Ti(OBu) 4 :EtOH:acac=1.8:120:0.09) in vacuum impregnation for 12 hours, then hydrolyzed in air, and then dried in air; finally, the sample was sintered to 550°C to obtain porous graded TiO 2 .

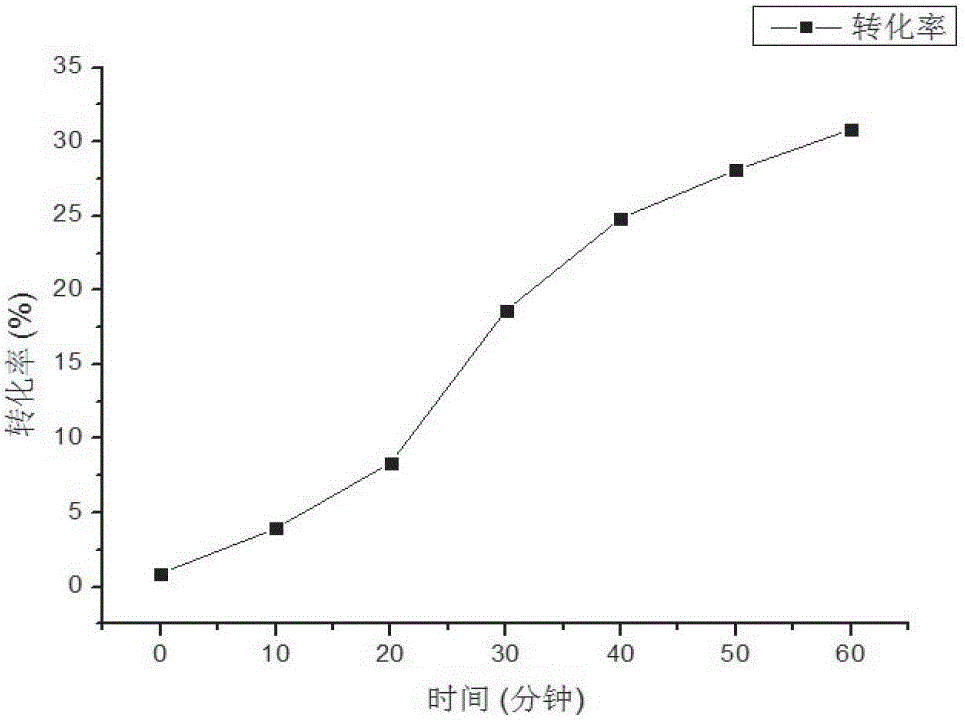

[0040] Add 0.2 g of TiO to 10 mL of chloroauric acid aqueous solution (5 mmol / L, adjusted to pH 6 by NaOH) 2 , magnetically stirred at 70 °C for 2 h. Then, the obtained powder was centrifuged, washed wit...

Embodiment 3

[0043] First, the natural corn leaves were cleaned to remove surface dust, and then soaked in freshly prepared PBS solution at 4°C for 12 hours, washed with distilled water, and stored at 0°C until use. After taking it out, put it at room temperature and soak it in 5% HCl solution for 3 hours until the green leaves turn yellow completely. Under vacuum conditions, the pretreated leaves were treated in 5% TiCl 3 Soak in water for 24 hours. After the above immersion, the leaves were dehydrated in gradients, that is, they were sequentially soaked in 15%→30%→50%→70%→85%→95%→100% absolute ethanol for 30 minutes respectively. Then the blade after dehydration is in tetra-n-butyl titanate / dehydrated alcohol / acetylacetone solution (volume ratio is: Ti(OBu) 4 :EtOH:acac=1.8:120:0.09) after vacuum impregnation for 12 hours, placed in air for hydrolysis and drying. Finally the blades are sintered at 550°C.

[0044] Add 0.3g of TiO to 10mL of chloroauric acid aqueous solution (5mmol / L, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com