Method for preparing composite electrode material, composite electrode material and battery

A composite electrode and battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high cost of preparation methods, complex synthesis processes, unfavorable environmental sustainable development, etc. effect on sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

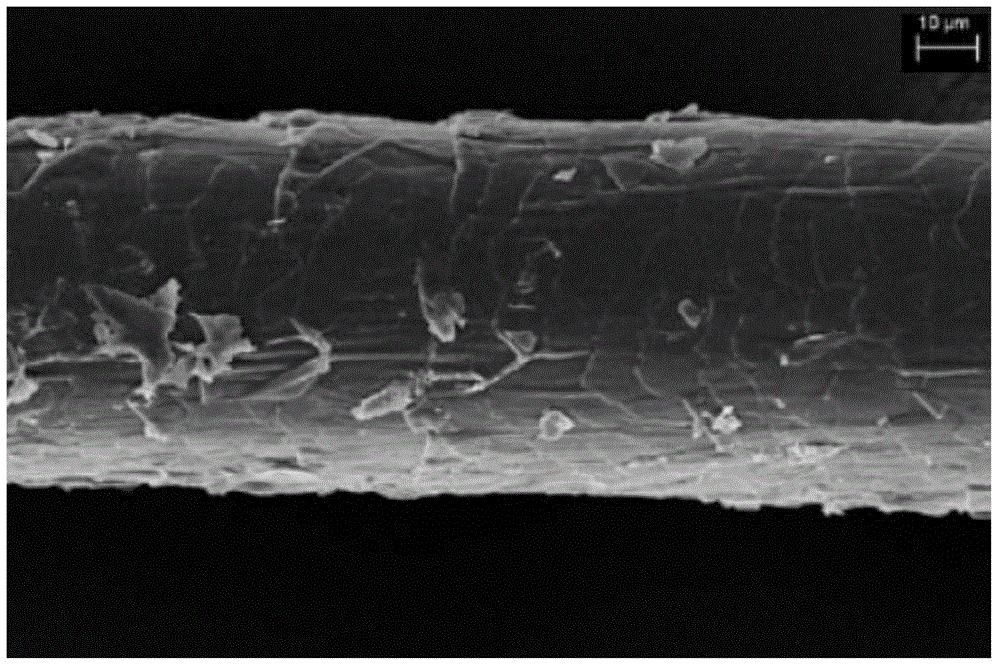

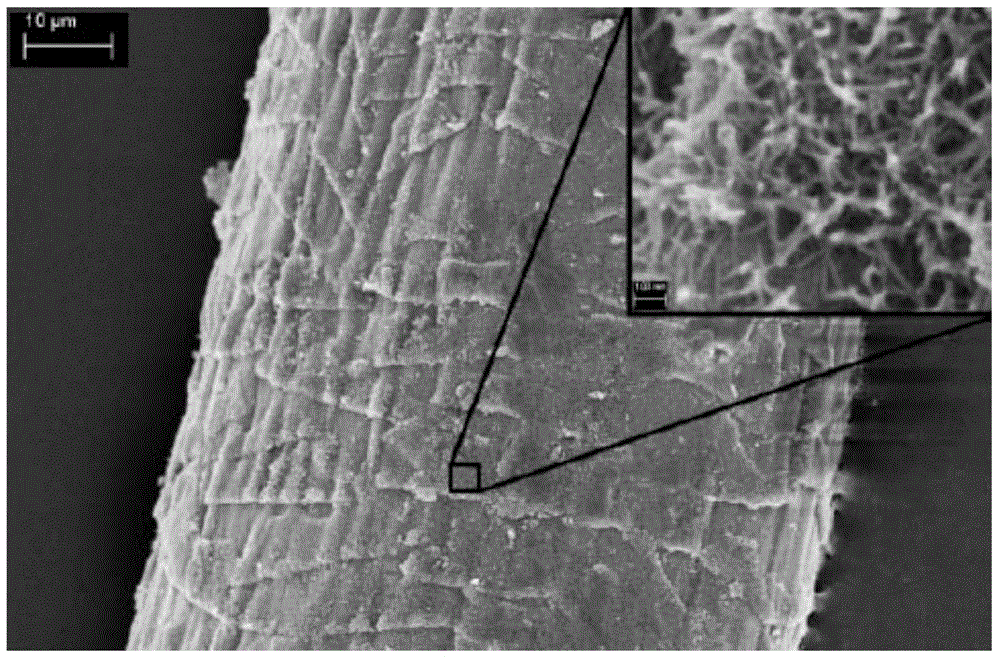

[0050] A preparation method of a composite electrode material, the preparation method comprising: contacting hair with an activator to activate the hair; dispersing the activated hair in a dispersion medium, adding a metal source solution for soaking to absorb metal ions, and then absorbing the metal The ionized hair is calcined in an oxygen-containing atmosphere or an inert atmosphere to obtain a composite electrode material containing metal oxide or metal sulfide.

[0051] The preparation method of the composite electrode material of the invention uses hair as a biological template to synthesize the composite electrode material with special structural properties through biomineralization.

[0052] Among them, the metal oxide may be an oxide of a single metal or a composite metal oxide. Similarly, the metal sulfide can be a single metal sulfide or a composite metal sulfide.

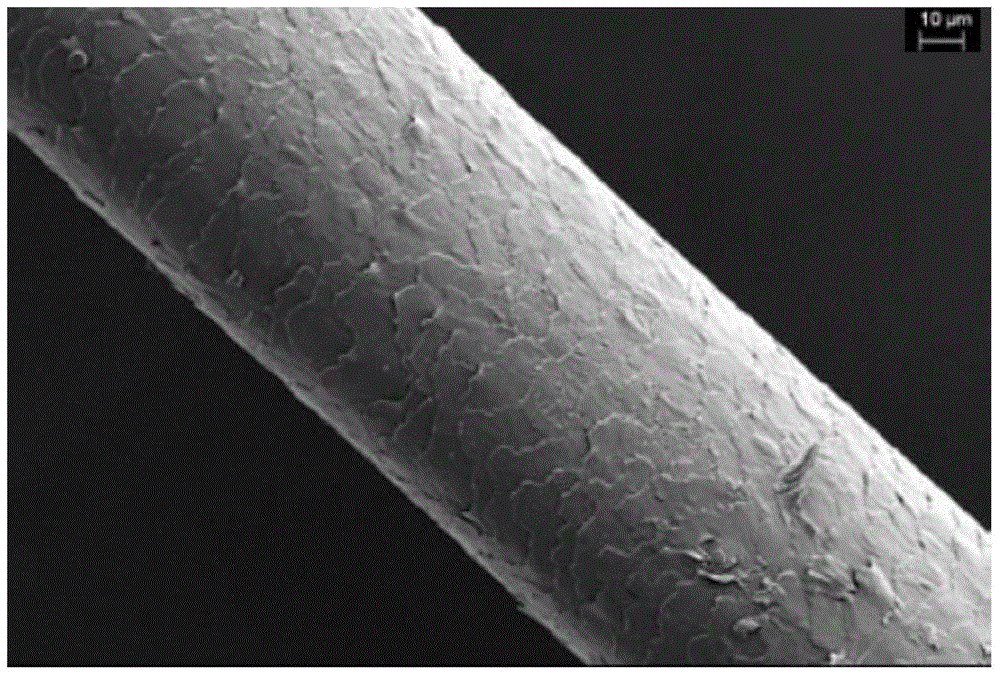

[0053] Hair is an elongated, thread-like product produced in the skin follicles of mammals. The dia...

Embodiment approach

[0070] In a preferred embodiment, the pre-cleaning includes washing the hair in ethanol for 30 minutes, and then washing the hair in 0.25 mol / L nitric acid solution for 30 minutes.

[0071] The pre-washed hair is immersed in the activator to activate it.

[0072] The purpose of the activation is to open the hair's sites of contact with water at the cuticle surface.

[0073] Preferably, the activator is selected from one or more of sodium hydroxide, lithium hydroxide, potassium hydroxide, sodium carbonate, potassium carbonate, sodium monohydrogen phosphate and potassium monohydrogen phosphate.

[0074] More preferably, the activator is selected from sodium hydroxide and / or lithium hydroxide.

[0075] Preferably, the concentration of the activator is 0.1-1 mol / L; more preferably 0.1-0.5 mol / L.

[0076] In this way, the hair can be fully activated, the combination of hair and metal ions, and the adsorption of metal ions on the hair can be enhanced, and at the same time, the los...

Embodiment 1

[0138] The hair collected from the barber shop is cut to a size of about 5 cm. Soak the cut hair in ethanol for 30 minutes, and then soak it in 0.25mol / L nitric acid aqueous solution for 30 minutes. Finally, soak and activate in 0.5mol / L NaOH aqueous solution for 1h. The revitalized hair is filtered, rinsed and dried.

[0139] 5 grams of the dried hair were weighed and dispersed in ethyl acetate to obtain a dispersion system. The metal source solution of 50ml (1mol / L Mg(NO 3 ) 2 , 1mol / L Mn(NO 3 ) 2 ) into the dispersion system. The dispersion was left at room temperature for 2h.

[0140] The hair was filtered from the dispersion, rinsed and dried at 110°C to constant weight.

[0141] The dried hair was calcined at 900° C. for 8 hours in an air atmosphere.

[0142] The obtained composite electrode material is denoted as A1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com