Three-dimensional light-emitting device formed by inverted light-emitting unit array and manufacturing method of three-dimensional light-emitting device

A technology of light-emitting units and light-emitting devices, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., to achieve the effects of simple process, elimination of process difficulties, and elimination of the preparation of silicon substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

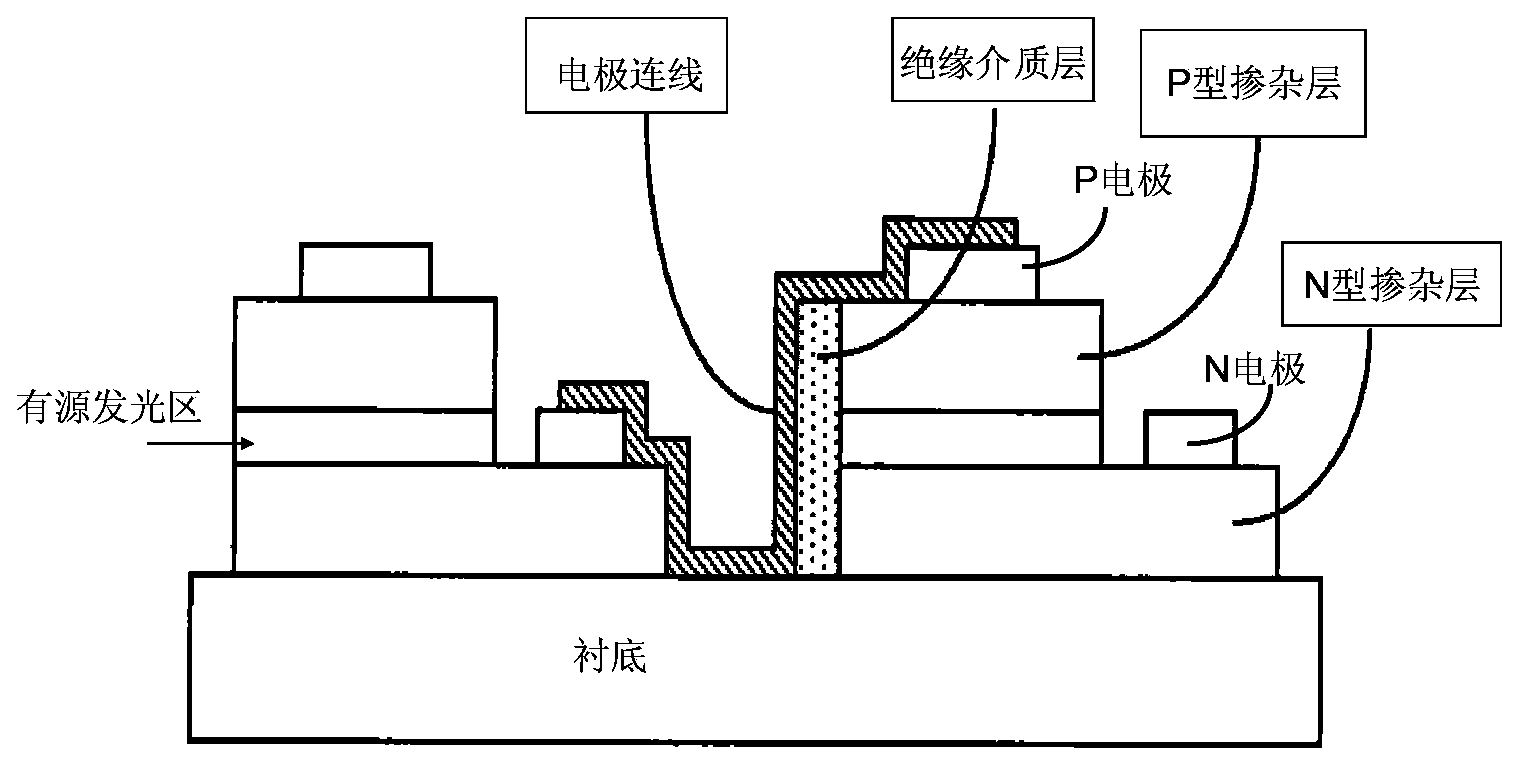

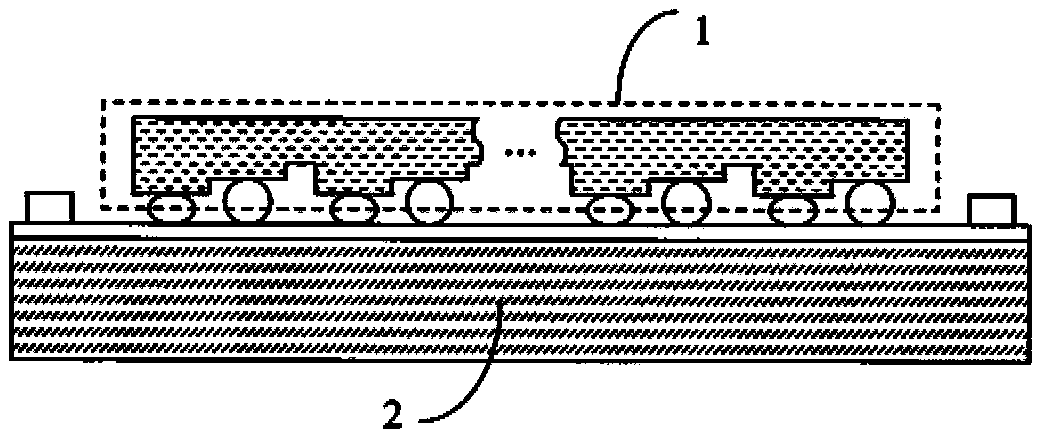

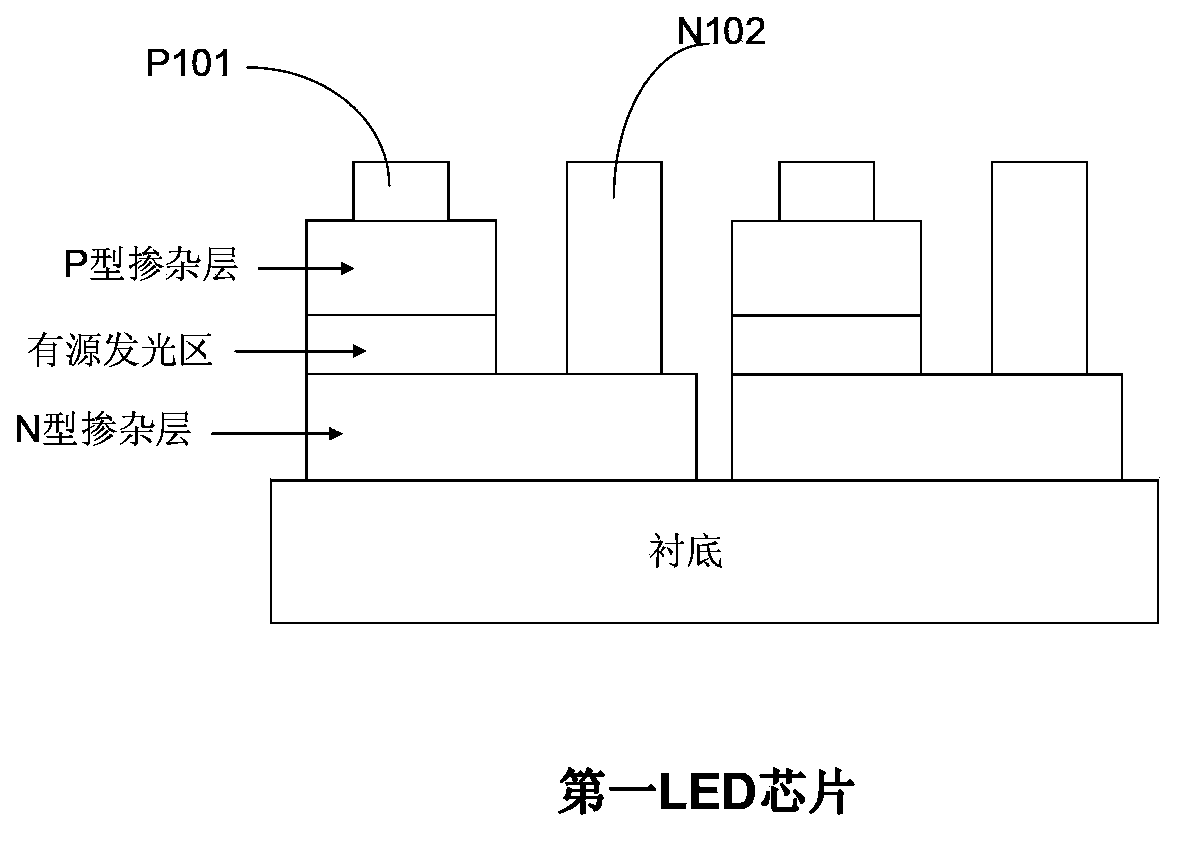

[0066] Please also see Figure 3 to Figure 7 , the three-dimensional light-emitting device in this embodiment consists of two LED light-emitting units of the first LED chip and three LED light-emitting units of the second LED chip to form a light-emitting array with five light-emitting units connected in series.

[0067] in, image 3 is a schematic cross-sectional view of the basic structure of the first LED chip; Figure 4 is a cross-sectional view of the basic structure of the second LED chip; Figure 5 It is a cross-sectional view of the basic structure of the three-dimensional light emitting device of the present invention after the first LED chip and the second LED chip are flip-chip connected; Image 6 It is a schematic diagram of the basic circuit of the three-dimensional light-emitting device of the present embodiment; Figure 7 The above is a schematic diagram of the layout design of the first LED chip, Figure 7 The following is a schematic diagram of the layout ...

Embodiment 2

[0073] Please also see Figure 3 to Figure 5 and Figure 8 , Figure 9 , the three-dimensional light-emitting device in this embodiment can be regarded as the series-parallel array structure of this embodiment formed by the two LED series arrays in Embodiment 1.

[0074] in, image 3 is a schematic cross-sectional view of the basic structure of the first LED chip; Figure 4 is a schematic cross-sectional view of the basic structure of the second LED chip; Figure 5 It is a schematic cross-sectional view of the basic structure of the three-dimensional light-emitting device of the present invention after the first LED chip and the second LED chip are flip-chip connected; Figure 8 It is a schematic diagram of the basic circuit of the three-dimensional light-emitting device of the present embodiment; Figure 9 The above is a schematic diagram of the layout design of the first LED chip, Figure 9 The following is a schematic diagram of the layout design of the second LED chi...

Embodiment 3

[0080] Please also see Figure 4 ,and Figure 10 to Figure 13 , the three-dimensional light-emitting device in this embodiment can be regarded as a light-emitting array with four light-emitting units connected in series consisting of one LED light-emitting unit and one independent area of the first LED chip and three LED light-emitting units of the second LED chip .

[0081] in, Figure 10 is a schematic cross-sectional view of the basic structure of the first LED chip; Figure 4 is a schematic cross-sectional view of the basic structure of the second LED chip; Figure 11 It is a schematic cross-sectional view of the basic structure of the three-dimensional light-emitting device of the present invention after the first LED chip and the second LED chip are flip-chip connected; Figure 12 It is a schematic diagram of the basic circuit of the three-dimensional light-emitting device of the present embodiment; Figure 13 The above is a schematic diagram of the layout design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com