Luminescent device formed by inverted luminous cell array and manufacture method thereof

A technology for light-emitting units and light-emitting devices, which is applied to electrical components, electrical solid-state devices, semiconductor devices, etc., can solve the problems of low production yield and complex process, and achieve the effect of improving production yield, simple process, and eliminating process difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

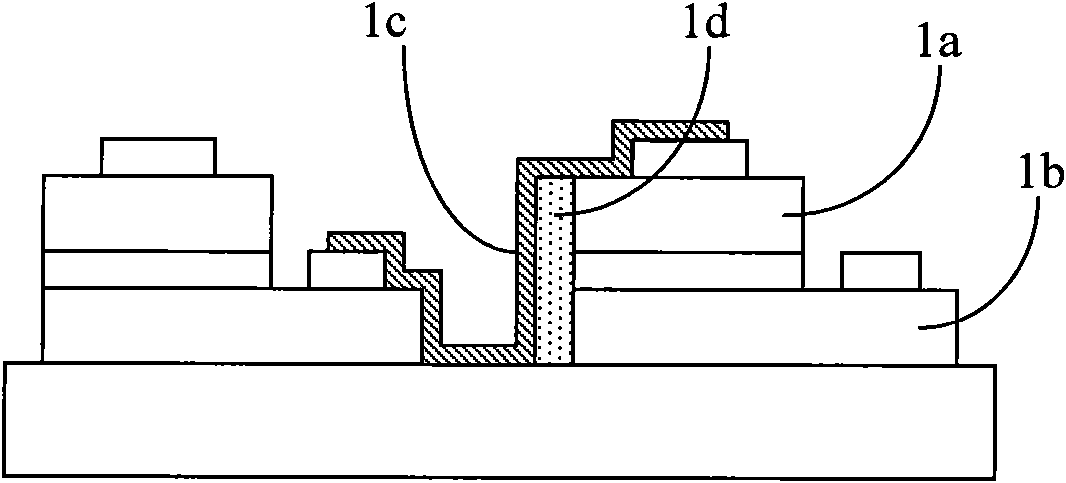

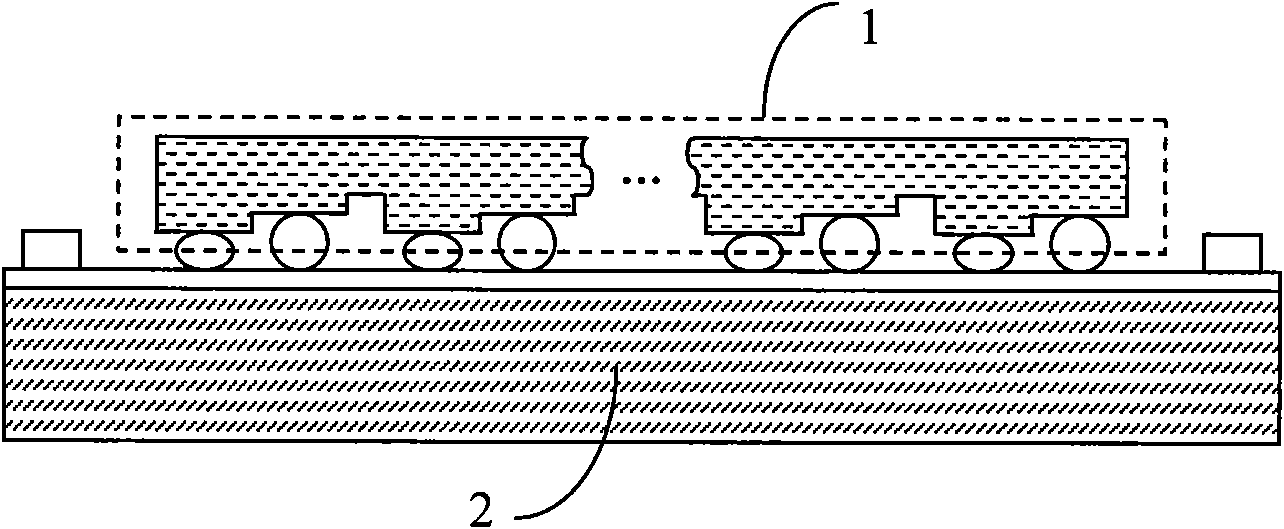

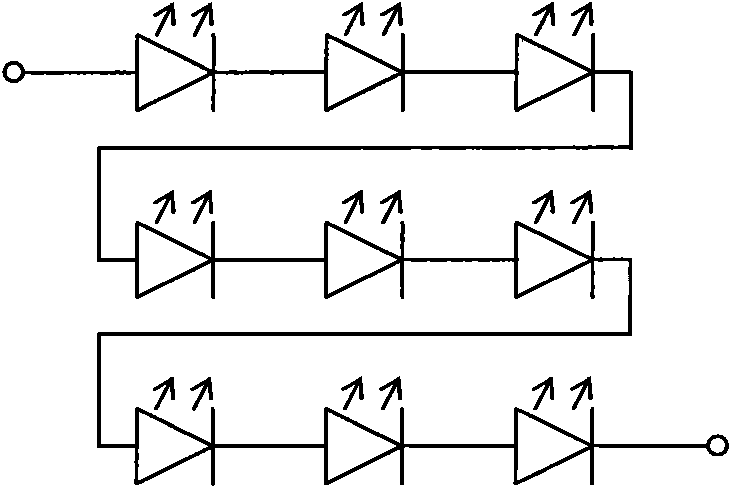

[0033] Please also see Figure 3 to Figure 7 ,in, image 3 is a schematic circuit diagram of Embodiment 1 of the light-emitting device of the present invention; Figure 4 It is a top view of the surface structure of Embodiment 1 of the light-emitting device of the present invention; Figure 5 yes Figure 4 A cross-sectional view of the light emitting device shown; Figure 6 yes Figure 4 The bottom view of the surface structure of the LED chip shown; Figure 7 yes Figure 4 Top view of the surface structure of the substrate shown.

[0034] The LED chip 1 of the light-emitting device in this embodiment has nine light-emitting units 101 connected in series. Physically, the nine light-emitting units 101 are distributed into three rows and three columns on the LED chip 1 . Each light emitting unit 101 has a P pole and an N pole respectively, the surface of the P pole is covered with the P pole solder ball 102 , and the surface of the N pole is covered with the N pole solder...

Embodiment 2

[0046] see Figure 8 , which is a top view of the surface structure of the substrate of Example 2 of the light-emitting device of the present invention. Embodiment 2 of the present invention is substantially the same as Embodiment 1, the only difference being that the LED chip 1 is flip-chip mounted on the substrate 2, each light emitting unit 101 is electrically connected to the metal wire layer 203 on the substrate 2, and Through the metal wire layer 203 , the mixed connection of three parallels and three strings is realized.

[0047] It can be deduced that the present invention can realize the change of the electrical connection between the multiple light emitting units 101 on the LED chip 1 only by changing the wiring of the metal wire layer 203 on the substrate 2 .

[0048] In addition, the present invention can also have various modified embodiments. For example, the bump solder balls can be arranged on the upper surface of the metal pad of the substrate, or can be arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com