Determination method for magnets in iron ore

A method of determination, iron ore technology, applied in the field of analysis and determination of chemical substances, can solve problems such as spectral line interference, poor accuracy, and large error in magnet determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Further description is given below in conjunction with specific implementation methods:

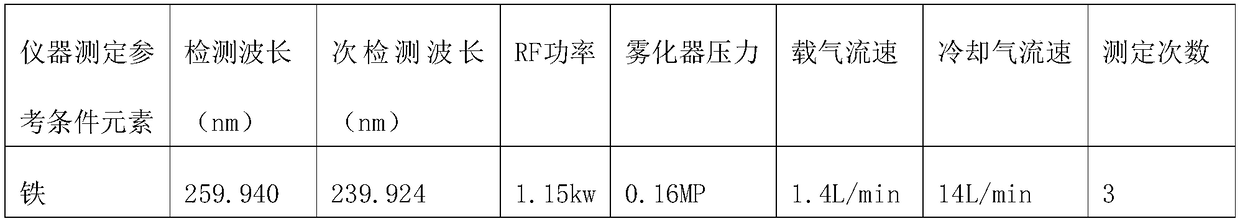

[0042] In the present embodiment, the whole measurement process is carried out according to the following steps:

[0043] 1. Prepare reagents and materials:

[0044]1.1 Iron standard stock solution: Weigh 1.0000g of spectroscopically pure metallic iron, put it in a 250ml beaker, add 20ml of water, 40ml of hydrochloric acid (1+1), add 1-2ml of nitric acid dropwise, heat on an electric heating plate, and heat at low temperature to make it completely Dissolve, boil for a few minutes, remove, cool to room temperature, transfer to a 1000ml volumetric flask, dilute to the mark with ultrapure water, shake well, the concentration of this solution is 1.0mg / ml;

[0045] 1.2 Hydrochloric acid ρ(HCl)=1.19g / ml, superior grade;

[0046] 1.3 Nitrate ρ(HNO3)=1.42g / ml, superior grade;

[0047] 1.4 Hydrochloric acid solution: 1+1, prepared with hydrochloric acid (1.2);

[0048] 1.5 Nitric acid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com